Detection method for sphere similarity of machine-made sand

A technology of sphere similarity and detection method, which is applied in the field of detection of machine-made sand sphere similarity, can solve problems such as inconvenient operation, unguaranteed accuracy, and inaccuracy, and achieve the effect of simple and accurate method, avoiding inconvenience, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

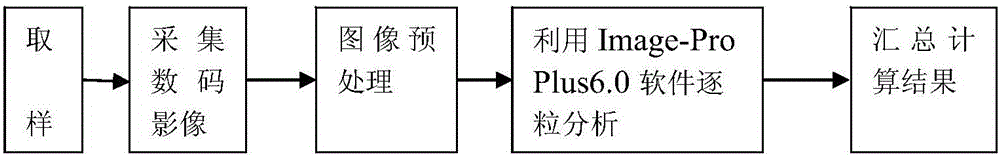

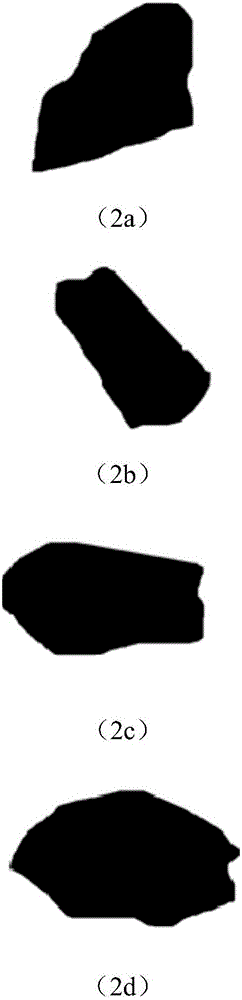

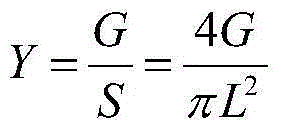

[0038] like figure 1 As shown, the test operation uses four projection figures in different directions as comparison objects. In fact, as many projection figures in different directions as possible should be selected for comparison. Using the method of particle sphere similarity, the present invention compares the particle morphology of machine-made sand with different qualities and river sand, including the following steps:

[0039] (1) Sampling

[0040] Randomly extract machine-made sand and river sand particles one by one, and place the selected particles on a clean glass plate.

[0041] (2) Acquisition of digital images

[0042] Use a digital camera to take pictures of machine-made sand and river sand particles from different directions. When taking pictures, care should be taken to ensure the quality of the pictures.

[0043] (3) Image preprocessing

[0044] Use image processing software to preprocess the picture, and process the digital image into a two-dimensional g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com