Preparation method for mixed hemimicelle solid-phase extraction agent based on DMSA@Fe3O4 magnetic nanoparticles

A technology of magnetic nanoparticles and mixed semimicelles, applied in chemical instruments and methods, alkali metal compounds, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

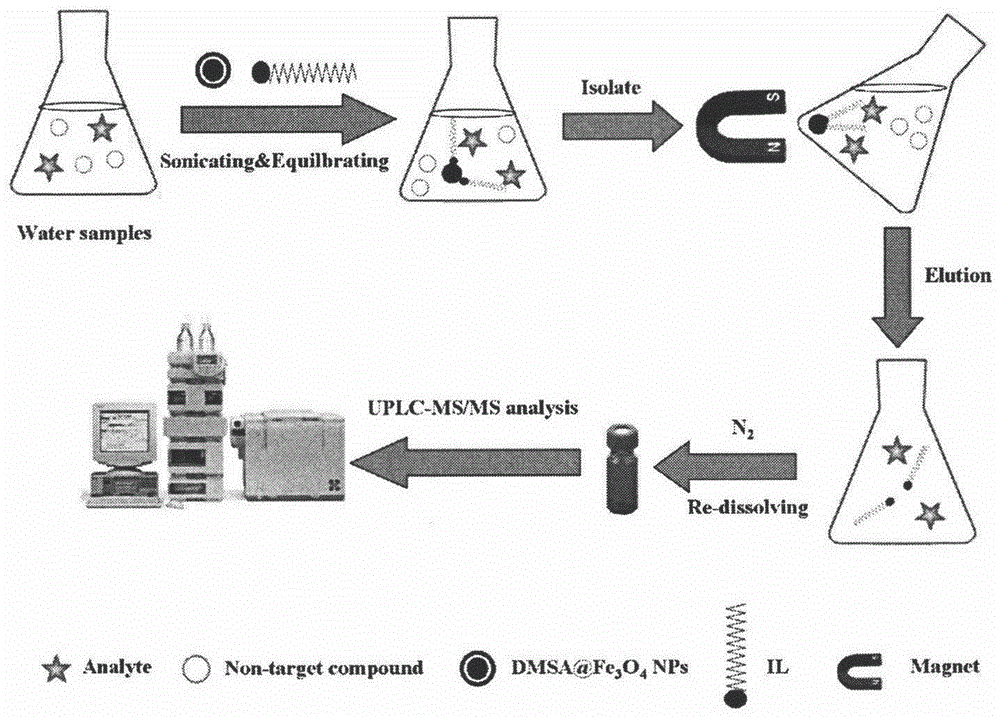

Method used

Image

Examples

Embodiment 1

[0027] After mixing 15mL oleylamine and 15mL benzyl ether, add 1.0596g iron acetylacetonate, and after ultrasonication for 20min, pour the mixed liquid into the lining of the reaction kettle, seal it, and place it in a muffle furnace for 2h at 185°C, and the reaction is over. After cooling to room temperature, washing with absolute ethanol several times, vacuum drying at 60°C to constant weight to obtain ferroferric oxide magnetic nanoparticles;

[0028] Disperse 10 mg of ferroferric oxide magnetic nanoparticles prepared above into 1 mL of toluene, add 1 mL of dimethyl sulfoxide solution dissolved with 10 mg of dimercaptosuccinic acid, sonicate for 2 h, place on a shaker at 25 ° C for 24 h, and then take it out. Wash with absolute ethanol, centrifuge 3 times, and finally disperse the obtained dimercaptosuccinic acid-modified ferroferric oxide magnetic nanoparticles in 1 mL of distilled water;

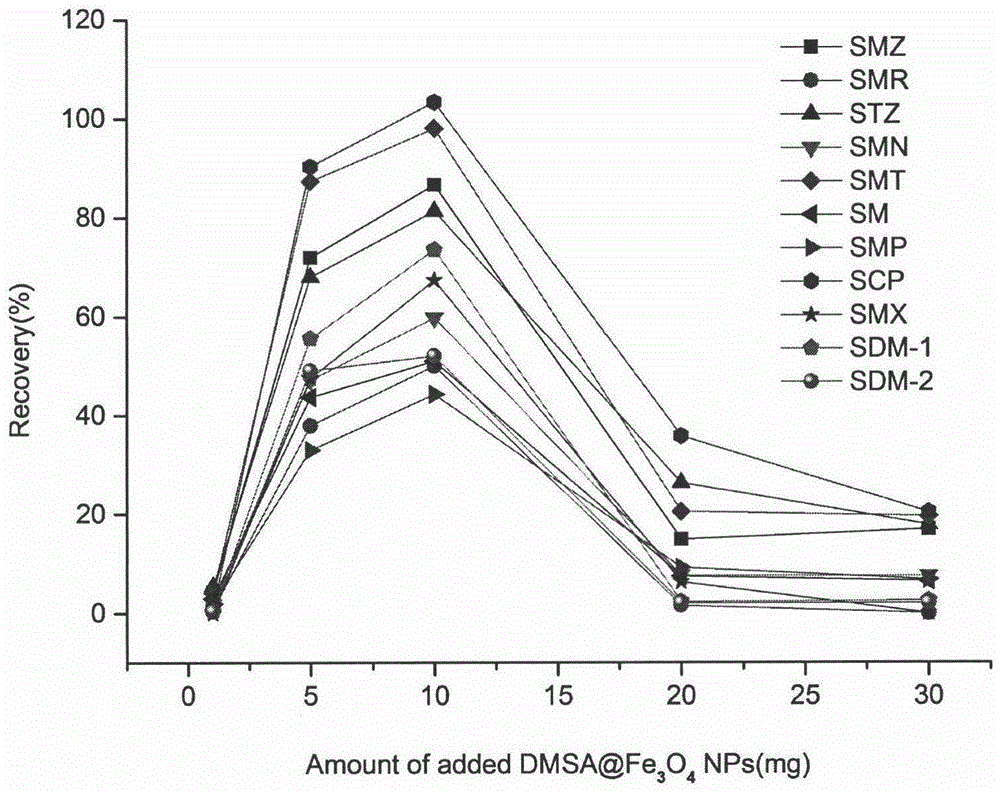

[0029] Take 50mL blank environmental water sample in the Erlenmeyer flask, adjust t...

Embodiment 2

[0031] After mixing 15mL oleylamine and 15mL benzyl ether, add 1.0596g iron acetylacetonate, and after ultrasonication for 20min, pour the mixed liquid into the lining of the reaction kettle, seal it, and place it in a muffle furnace for 2h at 185°C, and the reaction is over. After cooling to room temperature, washing with absolute ethanol several times, vacuum drying at 60°C to constant weight to obtain ferroferric oxide magnetic nanoparticles;

[0032] Disperse 10 mg of ferroferric oxide magnetic nanoparticles prepared above into 1 mL of toluene, add 1 mL of dimethyl sulfoxide solution dissolved with 10 mg of dimercaptosuccinic acid, sonicate for 2 h, place on a shaker at 25 ° C for 24 h, and then take it out. Wash with absolute ethanol, centrifuge 3 times, and finally disperse the obtained dimercaptosuccinic acid-modified ferroferric oxide magnetic nanoparticles in 1 mL of distilled water;

[0033] Take 100mL blank environmental water sample in the Erlenmeyer flask, adjust ...

Embodiment 3

[0035] After mixing 15mL oleylamine and 15mL benzyl ether, add 1.0596g iron acetylacetonate, and after ultrasonication for 20min, pour the mixed liquid into the lining of the reaction kettle, seal it, and place it in a muffle furnace for 2h at 185°C, and the reaction is over. After cooling to room temperature, washing with absolute ethanol several times, vacuum drying at 60°C to constant weight to obtain ferroferric oxide magnetic nanoparticles;

[0036] Disperse 10 mg of ferroferric oxide magnetic nanoparticles prepared above into 1 mL of toluene, add 1 mL of dimethyl sulfoxide solution dissolved with 10 mg of dimercaptosuccinic acid, sonicate for 2 h, place on a shaker at 25 ° C for 24 h, and then take it out. Wash with absolute ethanol, centrifuge 3 times, and finally disperse the obtained dimercaptosuccinic acid-modified ferroferric oxide magnetic nanoparticles in 1 mL of distilled water;

[0037] Take 50mL blank environmental water sample in the Erlenmeyer flask, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com