Modal analysis method of static pressure main spindle at micro scale

A technology of hydrostatic spindle and modal analysis, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as different influences, air thinning effects, errors, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

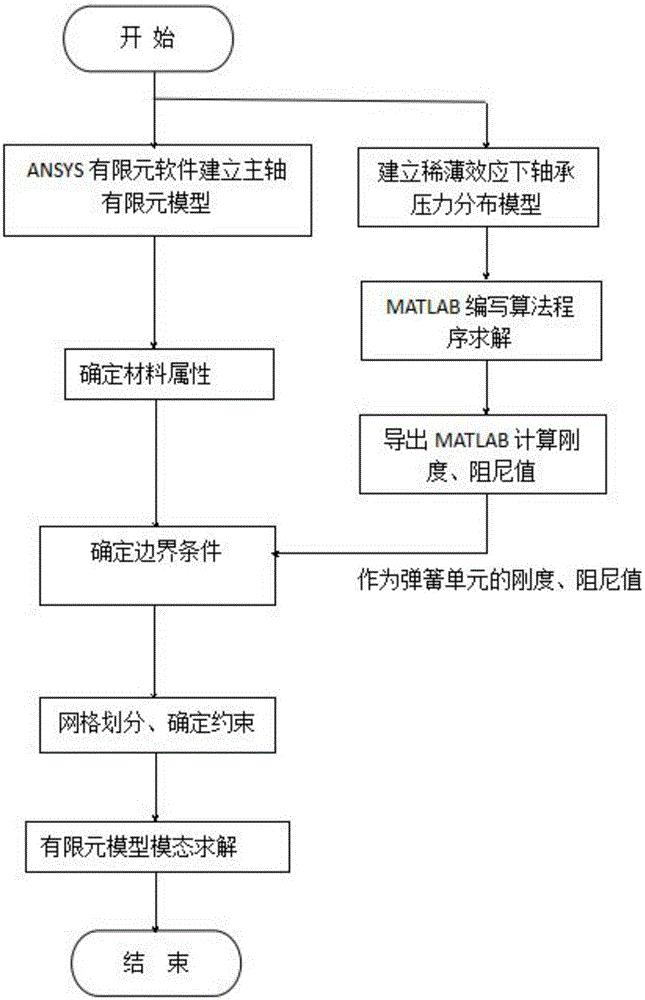

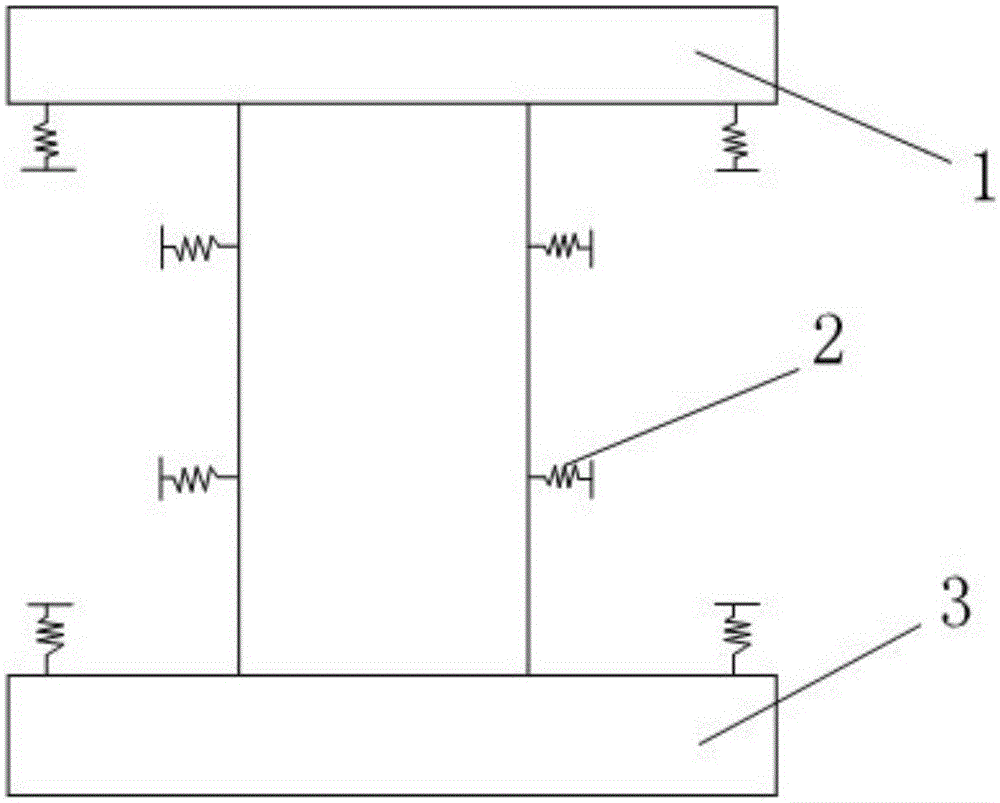

[0022] The method of the present invention is realized by a software program, including MATLAB and ANSYS software.

[0023] The flowchart of the method of the present invention is as figure 1 As shown, it specifically includes the following steps:

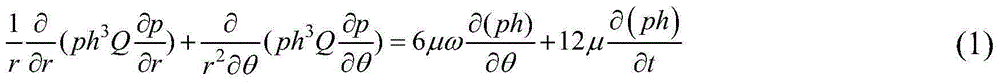

[0024] Step 1. According to the working condition of the static pressure spindle, the flow factor Q is used to simulate the rarefaction effect of the gas inside the bearing.

[0025] Step 2: Establishing the distribution model of the air film pressure of the hydrostatic bearing considering the rarefaction effect, taking the flow factor into account, and establishing the Reynolds equation at the microscale.

[0026] In step 3, the equation obtained in the previous step is dimensionless to facilitate further calculation and solution.

[0027] Step 4, write a program with MATLAB language, solve the dimensionless equation, and obtain the bearing air film pressure distribution.

[0028] Step 5, calculate the bearing stiffness and dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com