Transformer electromagnetic vibration noise calculating method based on finite element method

A finite element method and electromagnetic vibration technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of inaccurate models, difficult measurement, errors, etc., and achieve the effect of convenient data transmission and accurate and reliable calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

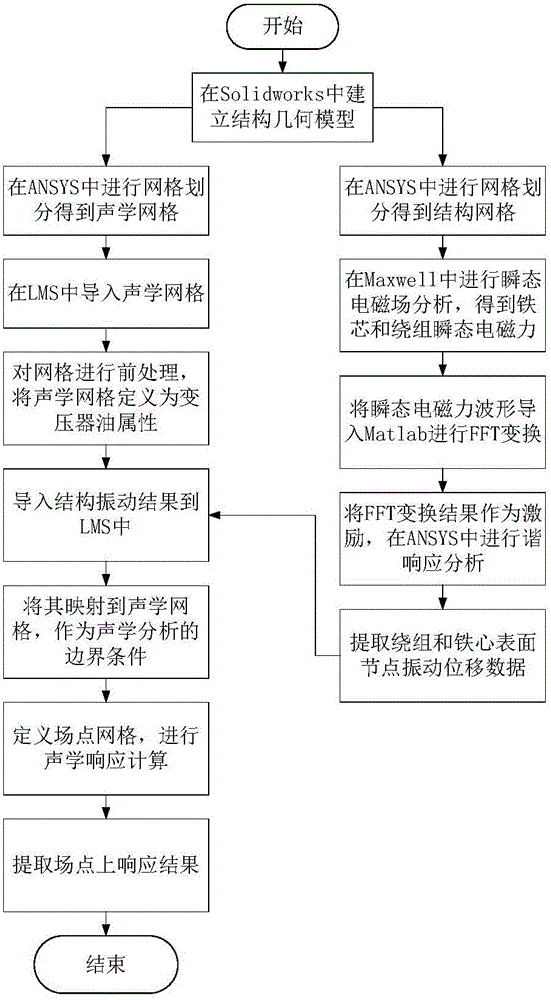

Method used

Image

Examples

Embodiment

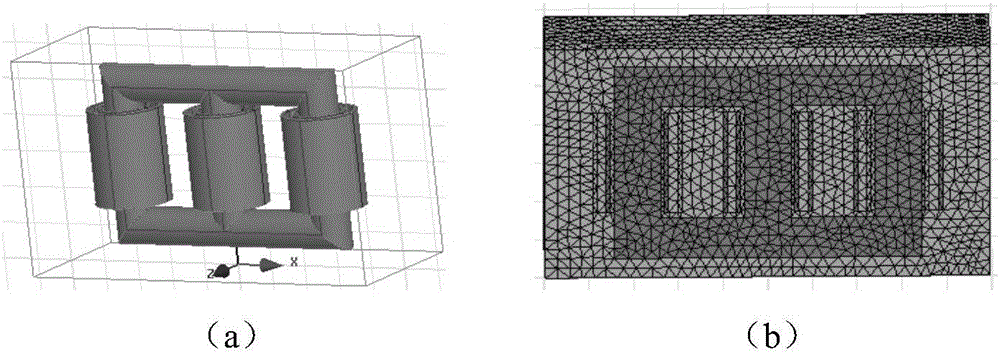

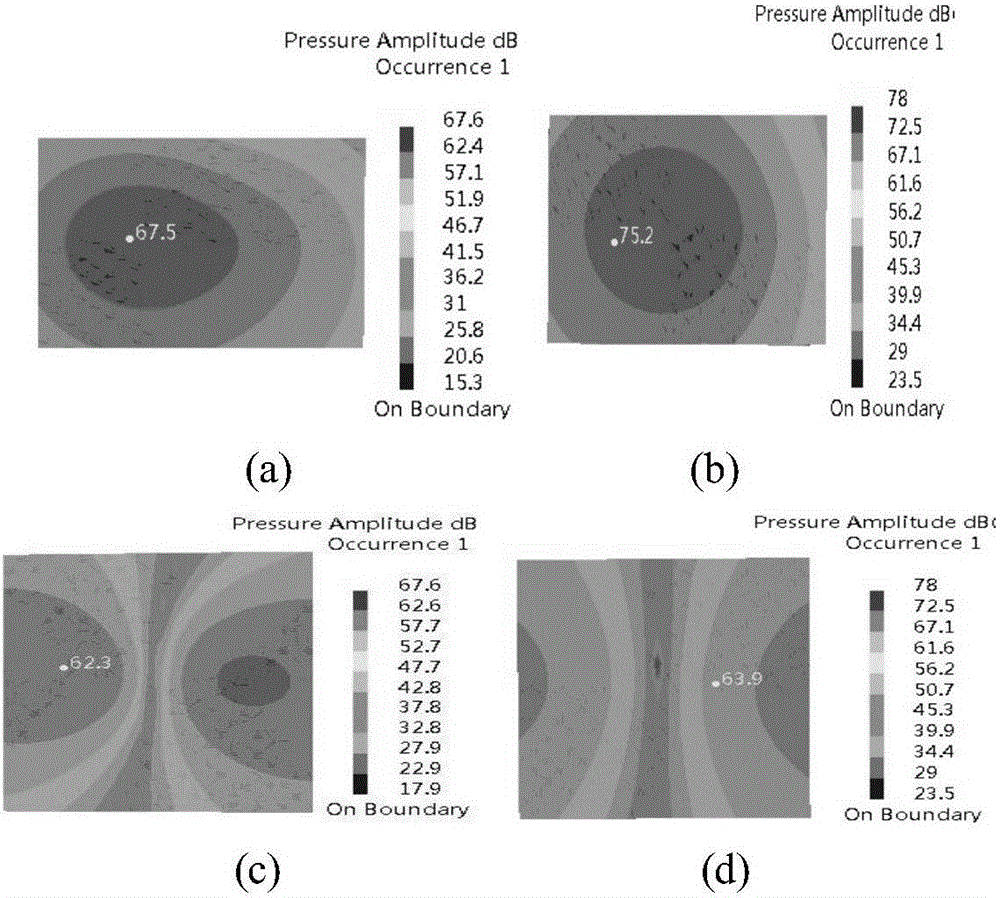

[0053] Taking a 110kV oil-immersed three-phase double-winding transformer as an example, the distribution of noise in the 100Hz and 200Hz frequency bands of the transformer on two different sides is calculated, and compared with the measured data.

[0054] In step 1, the rated current of the high-voltage winding is 165.3A, the rated current of the low-voltage winding is 1818.7A, the number of turns per phase of the high-voltage winding is 737 turns, the number of turns of each phase of the low-voltage winding is 116 turns, and the coil diameter of the high-voltage winding is 948mm to 1111mm. The diameter of the winding coil is 598mm-710mm, the height of the winding coil is 1216mm, the diameter of the iron core is 565mm, the height of the iron core yoke is 540mm, and the volume of the oil tank is 5m*2m*3m. Based on the above structural parameters, a three-dimensional geometric model of the transformer is established.

[0055] In step 2, set the stacking coefficient to 0.95, set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com