Preparation method of circle-oriented non-crystal magnetic powder core

A magnetic powder core, amorphous technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of easily destroying the insulating coating, reducing the magnetic permeability of the magnetic powder core, increasing the total loss of the magnetic powder core, etc. Significant anisotropy, increase in permeability, increase in product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

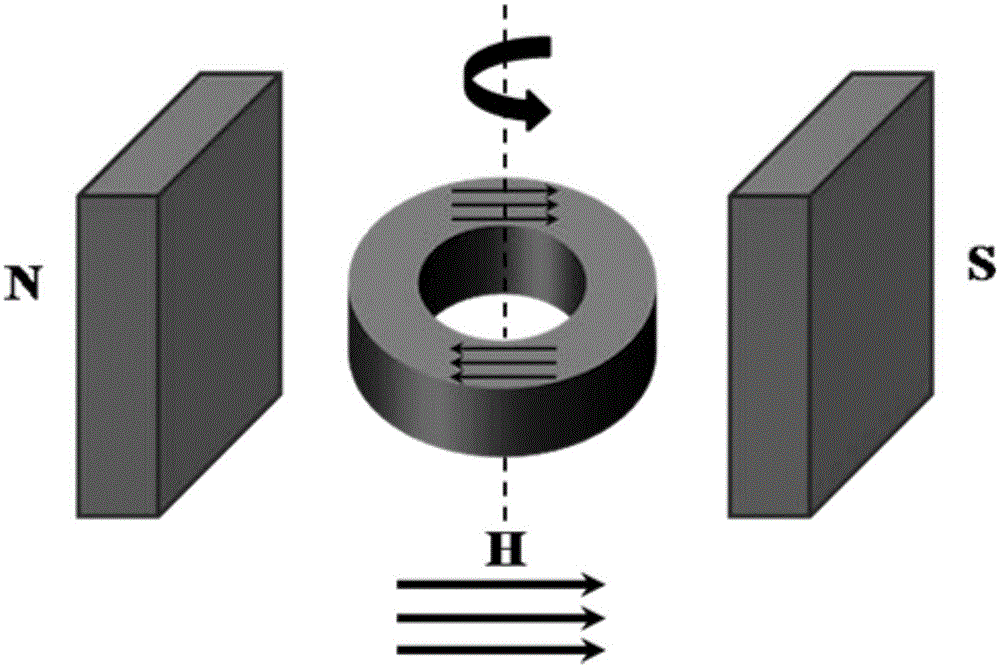

Embodiment 1

[0024] will be composed of Fe 78 Si 9 B 13 The scaly amorphous magnetic powder is sieved and mixed into a powder consisting of 10% of the first powder passing through -100 to +200 mesh, 55% of the second powder passing through -200~+300 mesh and 35% of the third powder passing through -300 mesh Proportioned powder, passivate the proportioned amorphous powder, then dry the powder, add binder and insulating agent to the passivated amorphous powder and mix evenly, among them, the scaly amorphous magnetic powder The dosage is 90% of the total weight of the compound; the insulating coated amorphous magnetic powder is evenly loaded into a non-magnetic permeable mold, and then the mold is placed in a horizontal external magnetic field of 0.8T and vibrated, and then rotated at 45° Rotate the mold, and pre-press and fix the oriented magnetic powder along the circular direction successively, and then place the pre-pressed magnetic powder core in a powder tablet press for pressing at a...

Embodiment 2

[0026] will be composed of Fe 78 Si 9 B 13 The scaly amorphous magnetic powder is sieved and mixed into a powder consisting of 10% of the first powder passing through -100 to +200 mesh, 55% of the second powder passing through -200~+300 mesh and 35% of the third powder passing through -300 mesh Proportioned powder, passivate the proportioned amorphous powder, then dry the powder, add binder and insulating agent to the passivated amorphous powder and mix evenly, among them, the scaly amorphous magnetic powder The dosage is 80% of the total weight of the compound; the insulating coated amorphous magnetic powder is evenly loaded into a non-magnetic permeable mold, and then the mold is placed in a horizontal external magnetic field of 0.5T and vibrated, and then the mold is vibrated at 60° Rotate the mold, and pre-press and fix the oriented magnetic powder along the circular direction successively, and then place the pre-pressed magnetic powder core in a powder tablet press for ...

Embodiment 3

[0028] will be composed of Fe 78 Si 9 B 13 The scaly amorphous magnetic powder is sieved and mixed into a powder consisting of 10% of the first powder passing through -100 to +200 mesh, 55% of the second powder passing through -200~+300 mesh and 35% of the third powder passing through -300 mesh Proportioned powder, passivate the proportioned amorphous powder, then dry the powder, add binder and insulating agent to the passivated amorphous powder and mix evenly, among them, the scaly amorphous magnetic powder The dosage is 95% of the total weight of the compound; the insulating coated amorphous magnetic powder is evenly packed into a non-magnetic permeable mold, and then the mold is placed in a horizontal external magnetic field of 1.0T and vibrated, and then rotated at 30° Rotate the mold, and pre-press and fix the oriented magnetic powder along the circular direction successively, and then place the pre-pressed magnetic powder core in a powder tablet press for pressing at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com