Bowl Flange Submersible Thick Film Heater

A thick film heater and thick film heating technology, which is applied in immersion heating devices, ohmic resistance heating parts, etc., to improve convection efficiency and solve unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

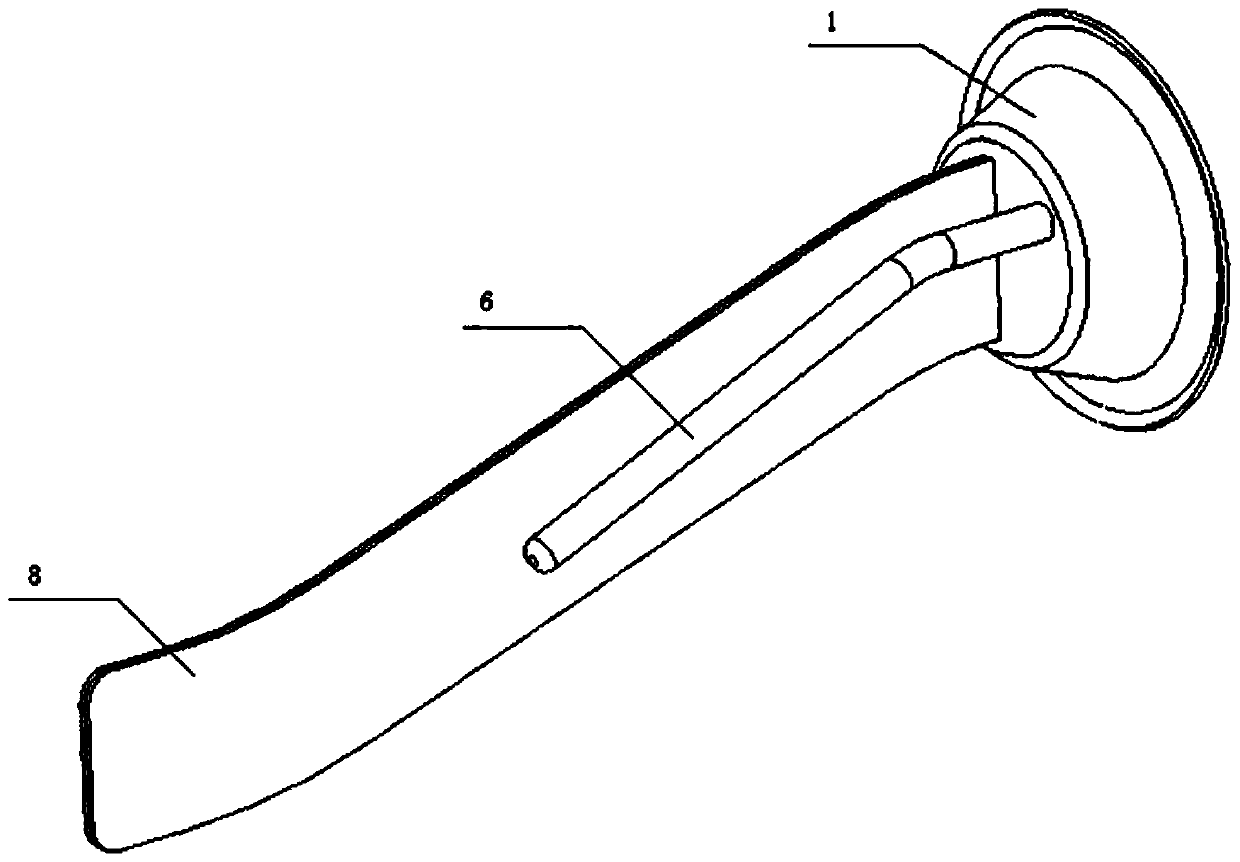

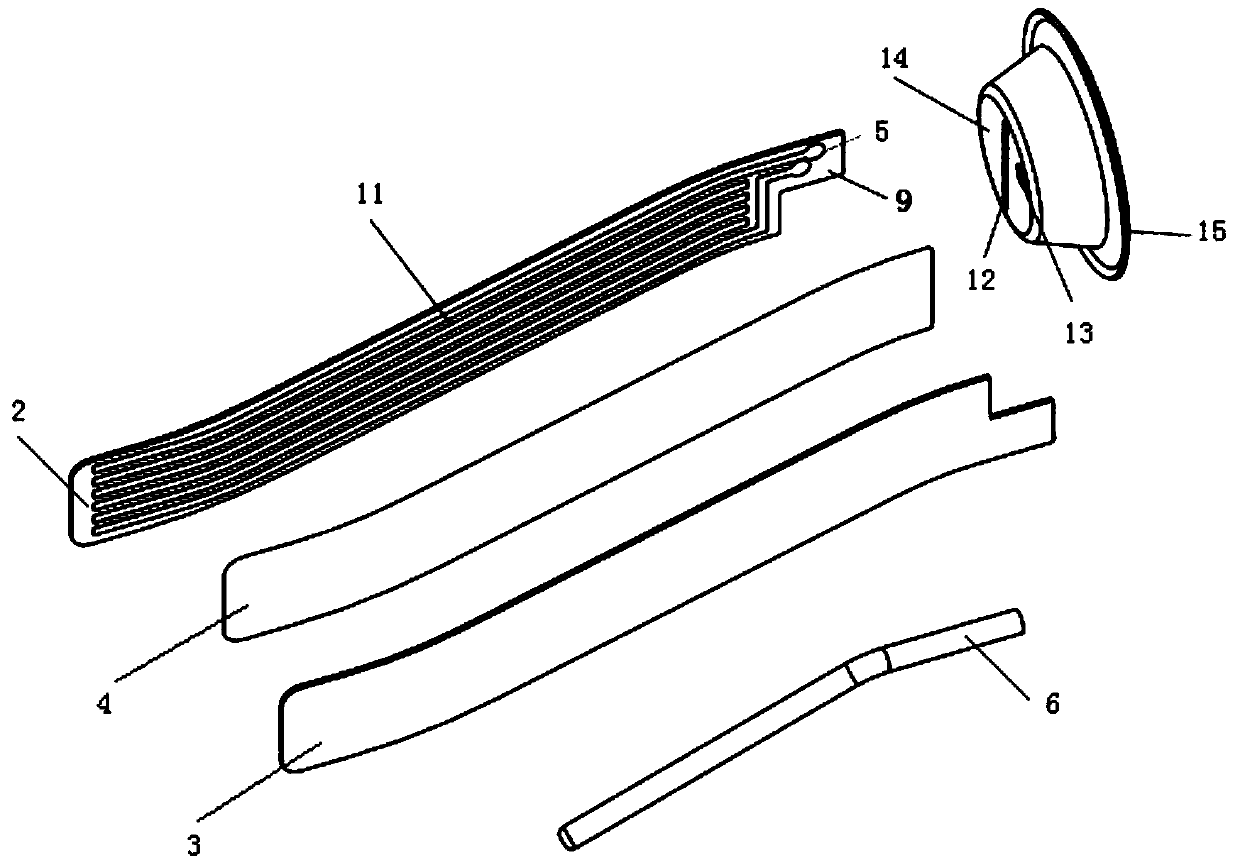

[0030] Such as figure 1 with figure 2 As shown, a bowl-type flange submerged thick-film heater includes a flange 1, a first heating substrate 2, a second heating substrate 3, insulating paper 4 and a temperature detection tube 6, and the first heating substrate , the second heating substrate, and insulating paper constitute the thick film heating body 8 . The lower edge of the thick film heater is offset from the axis of the flange by 15 cm.

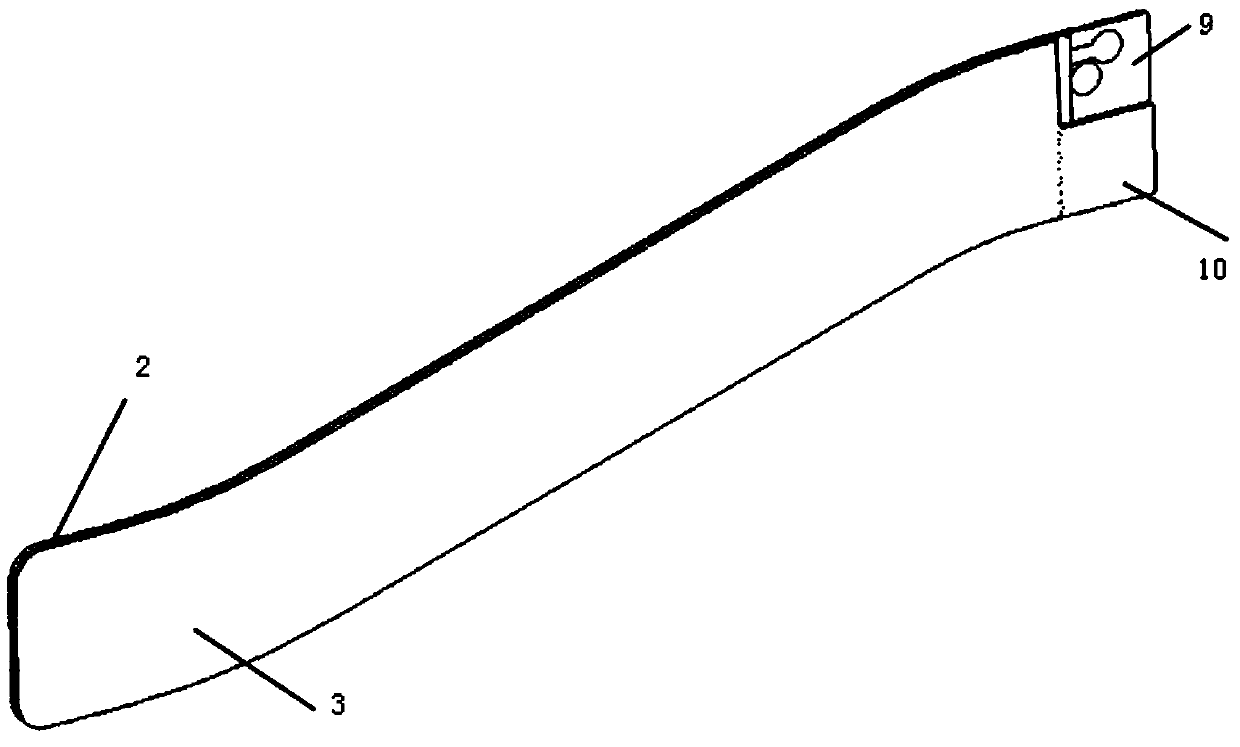

[0031] According to the requirements of the diving depth of the first heating substrate and the second heating substrate, both the first heating substrate and the second heating substrate are arc-shaped, and the single surface area of the first heating substrate and the second heating substrate is designed to be 250cm². One end of the first heating substrate has a first extending end 9, and one end of the second heating substrate has a second extending end 10. The mirror images of the substrates overlap, and the first protruding en...

Embodiment 2

[0036] Such as Figure 5 As shown, both the first heating substrate and the second heating substrate are S-shaped, with a large degree of curvature, and the others are the same as those in Embodiment 1.

Embodiment 3

[0038] Such as Image 6 As shown, on the basis of Embodiment 1, the preset positioning sheet 7 is added, and the ends of the first extension end 9 and the second extension end 10 of the thick film heating body are passed through the rectangular through hole 12 of the flange, so that the preset The positioning piece is closely attached to the lower end surface 14 of the flange, and the gap between the positioning piece and the lower end surface of the flange is preset by laser sealing welding thick film heating body; Laser sealing and welding the gap between the temperature detection tube and the lower end surface of the flange; spraying fluororesin on the lower end surface 14 of the flange, the outer surface of the thick film heating body, and the outer surface of the temperature detection tube. Finally, the power connection line and the lead connection end 5 are welded by soldering, and then the concave surface of the flange is potted with silica gel, so as to strengthen the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com