Steel structure for hydrogen, and method for manufacturing pressure accumulator for hydrogen and line pipe for hydrogen

A manufacturing method and hydrogen storage container technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of not easy hydrogen embrittlement, the inability to use low alloy steel, and the high price of hydrogen storage containers, and achieve hydrogen embrittlement resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

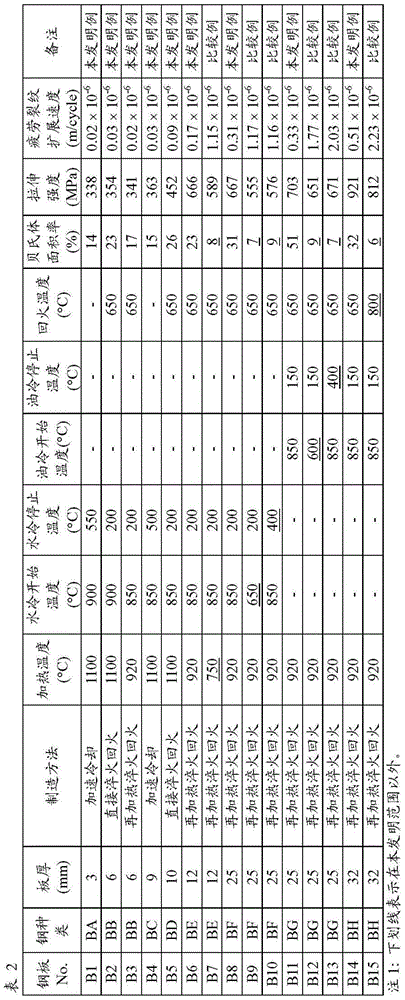

[0156] (invention 1)

[0157] Hereinafter, examples for verifying the effects of the present invention will be described regarding the invention (Invention 1) of a steel structure for hydrogen having a steel structure composed of bainite and a remainder substantially ferrite. In addition, in the following examples, the manufacturing method and characteristic evaluation of the steel plate were simulated (simulation) for the manufacturing method and characteristic evaluation of the hydrogen pipe and the hydrogen storage container. Specifically, when the manufacturing method is accelerated cooling or direct quenching and tempering, the case of hydrogen pipelines is simulated, and when reheating and quenching and tempering (reheating, quenching and tempering) are performed, hydrogen storage tanks are simulated Case.

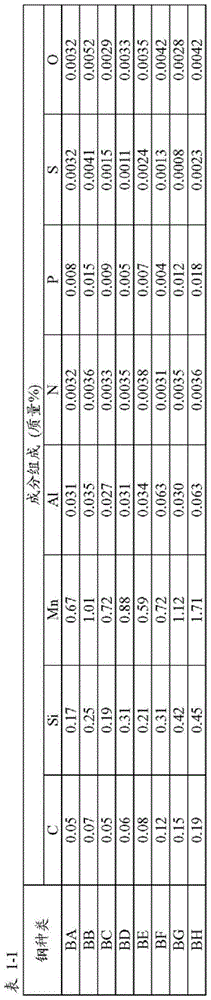

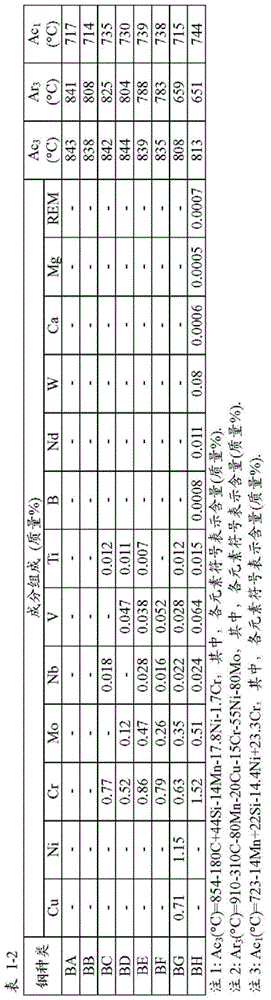

[0158] Steels BA to BH with the chemical compositions shown in Table 1 (Table 1-1, Table 1-2) were melted and cast into billets, heated to the heating temperature s...

Embodiment 2

[0173] (Invention 2)

[0174] Hereinafter, an example for verifying the effects of the present invention will be described regarding the invention (Invention 2) of a steel structure for hydrogen having a steel structure composed of martensite and the remainder substantially ferrite. In the following examples, the manufacturing method and characteristic evaluation of the steel plate were simulated in the same manner as in Example 1, and the manufacturing method and characteristic evaluation of the hydrogen pipe and the hydrogen storage container were simulated. Specifically, when the manufacturing method is accelerated cooling or direct quenching and tempering, the case of hydrogen pipelines is simulated, and when reheating and quenching and tempering (reheating, quenching and tempering) are performed, hydrogen storage tanks are simulated Case.

[0175] Steels MA to MH with the chemical compositions shown in Table 3 (Table 3-1, Table 3-2) were melted and cast into billets, hea...

Embodiment 3

[0190] (Invention 3)

[0191] Hereinafter, examples for verifying the effects of the present invention will be described regarding the invention (Invention 3) of a steel structure for hydrogen having a steel structure composed of pearlite and the remainder substantially ferrite. In the following examples, the manufacturing method and characteristic evaluation of the steel plate were simulated in the same manner as in Example 1, and the manufacturing method and characteristic evaluation of the hydrogen pipe and the hydrogen storage container were simulated. Specifically, when the manufacturing method is accelerated cooling or direct quenching and tempering, the case of hydrogen pipelines is simulated, and when reheating and quenching and tempering (reheating, quenching and tempering) are performed, hydrogen storage tanks are simulated Case.

[0192] Steels PA to PH with the chemical compositions shown in Table 5 (Table 5-1, Table 5-2) were melted and cast into steel slabs, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com