Device for conserving power in a piston compressor

A power-saving, compressor technology, applied in piston pumps, mechanical equipment, machines/engines, etc., can solve the problems of lubricating oil concentration, affecting compressor efficiency, etc., to achieve the effect of power saving and power saving optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

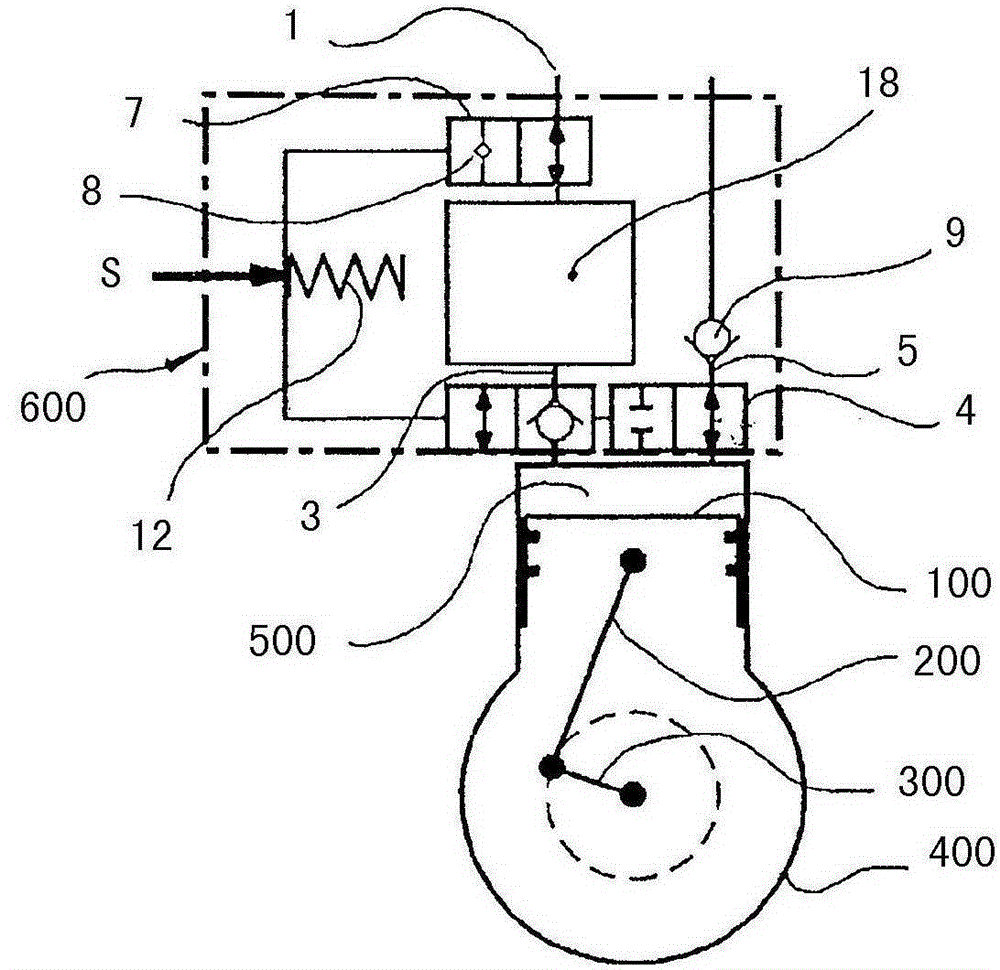

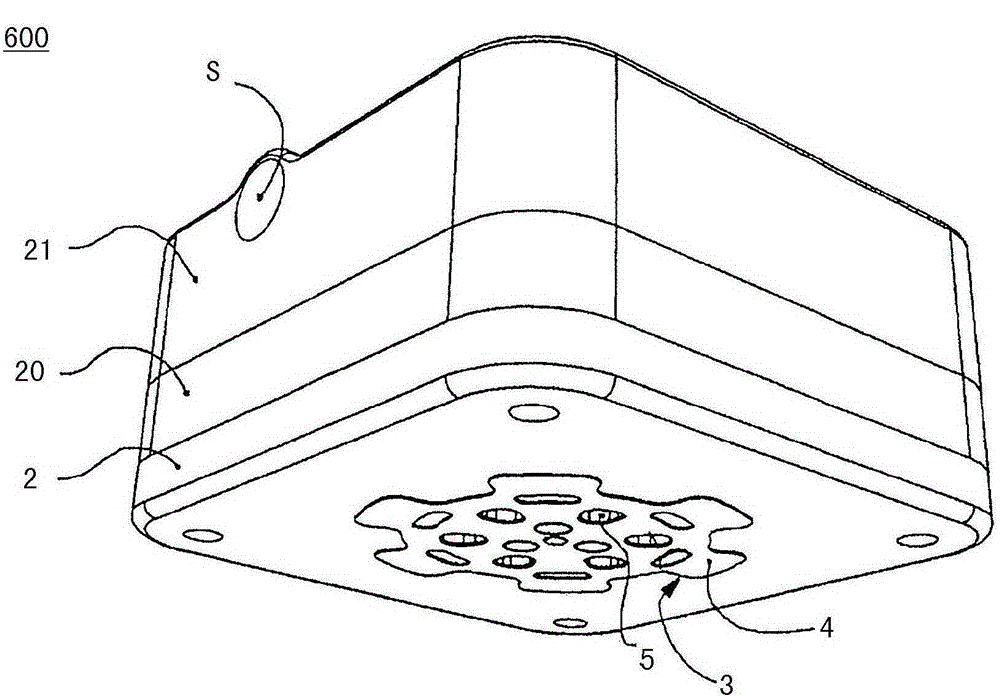

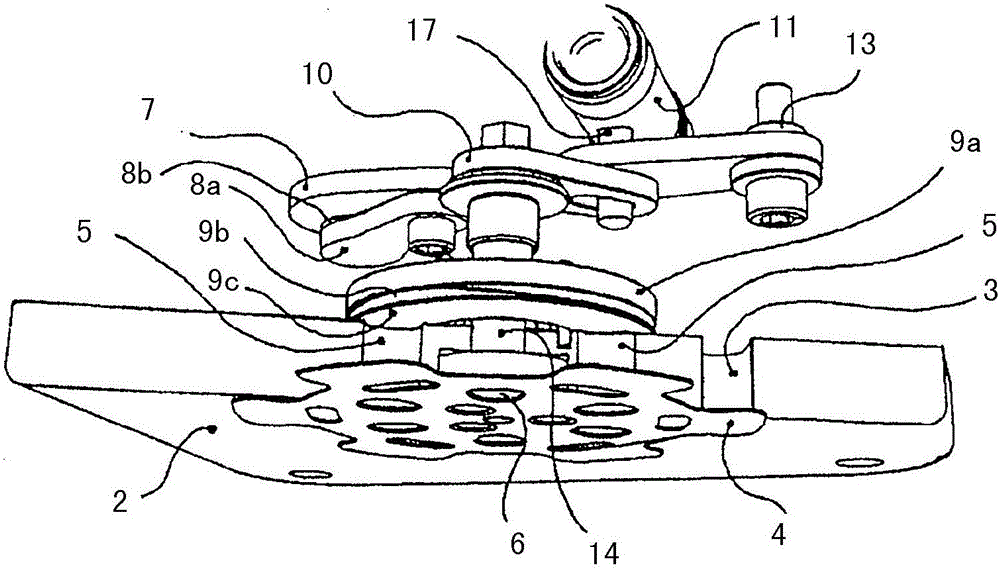

[0033] according to figure 1 , a piston compressor for generating compressed air basically comprises a piston 100 articulated to a driven crankshaft 300 via a connecting rod 200 . Crankshaft 300 is rotatably supported in crankcase 400 . The crankcase 400 comprises a cylinder which together with the piston 100 forms a compression chamber 500 which is provided at the end with a cylinder head 600 which is only schematically shown here and which has a power-saving lever integrated into the cylinder head. installation.

[0034] The cylinder head 600 comprises a slide 7 with an integrated minimum air valve 8 which acts as a 2 / 2-way valve and controls the suction connection 1 of the piston compressor. The ambient air sucked in via the suction connection 1 passes via the slide 7 in the cylinder head 600 to the suction chamber 18 which is formed in the cylinder head and serves as a connectable clearance space. In the direction of the compression chamber 500 , the suction chamber 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com