A method for cleaning the surface of electrical components and precision hydraulic components with dry ice

A technology for dry ice cleaning and hydraulic parts, applied in chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of reducing equipment assembly accuracy, easily damaged equipment, low safety performance, etc., to reduce bump damage, save time, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

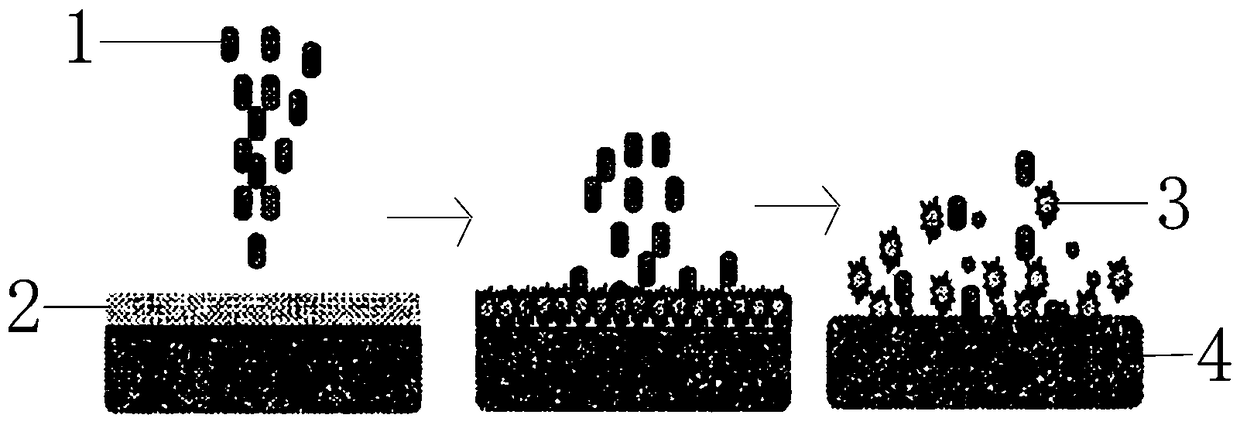

[0016] Embodiment 1: a kind of method of dry ice cleaning electric device and precision hydraulic parts surface, comprises the following steps:

[0017] (1) Pre-treatment of the workpiece: block the valve block, remove the oil on the surface of the workpiece; close the door of the electric control box;

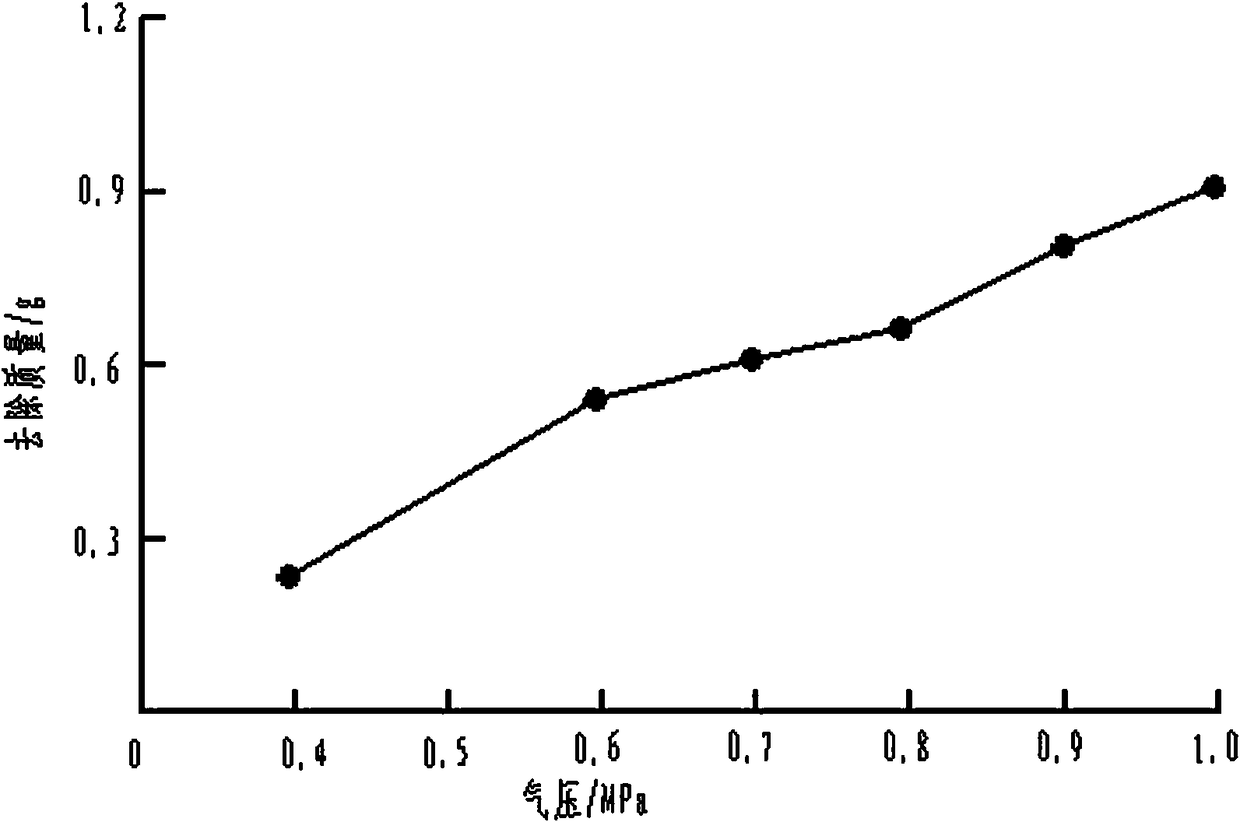

[0018] (2) The dry ice blasting machine is equipped with solid spherical dry ice particles with a diameter of 2mm. The dry ice blasting machine is connected to a voltage of 220V and connected to a pressure of ≥0.8MPA. After turning on the switch, set the pressure of the air compressor to 0.4MPa and the flow rate to 3.5 cubic meters / minute, the distance between the nozzle and the surface to be cleaned is 25mm, press the button of the spray gun, aim at the surface of the object to be cleaned and spray, adjust the distance between the nozzle and the cleaning surface according to the difficulty of cleaning the dirt, adjust the nozzle and the cleaning surface according to the clea...

Embodiment 2

[0024] Embodiment 2: a kind of method for cleaning the surface of electrical parts and precision hydraulic parts with dry ice, solid spherical dry ice particles with a diameter of 3mm in the dry ice cleaning machine, the pressure of the air compressor is set to 0.9MPa, and the flow rate is: 0.5 cubic meters per minute. The amount of ice is 50kg / h, the injection pressure is 7bar, and the rest of the steps are the same as those described in Example 1.

Embodiment 3

[0025] Embodiment 3: A kind of method for cleaning the surface of electrical parts and precision hydraulic parts with dry ice, solid spherical dry ice particles with a diameter of 4mm are installed in the dry ice cleaning machine, the pressure of the air compressor is set to 1MPa, and the flow rate is: 2.5 cubic meters per minute. Amount is 30kg / h, and injection pressure is 7.5bar, and all the other steps are with the step described in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com