Automobile exhaust manifold small-head end drilling tool

A technology for drilling tooling and automobile exhaust, which is used in boring/drilling, drilling/drilling equipment, manufacturing tools, etc. The effect of convenient and quick disassembly and assembly, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

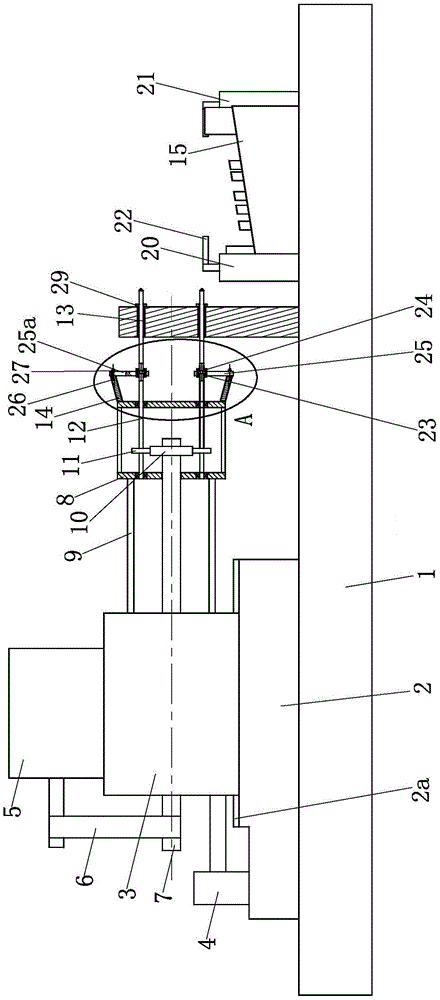

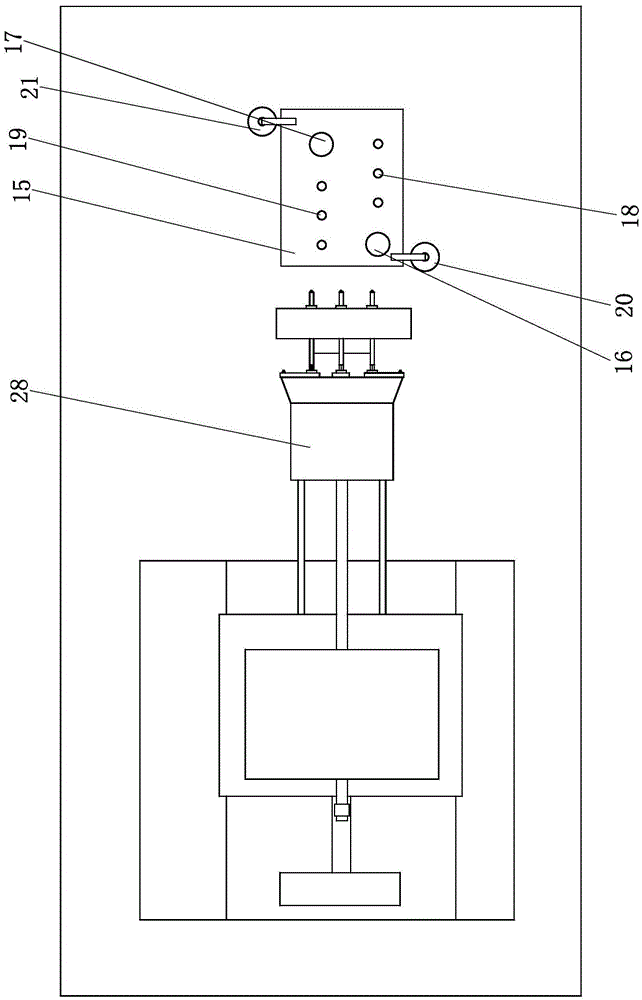

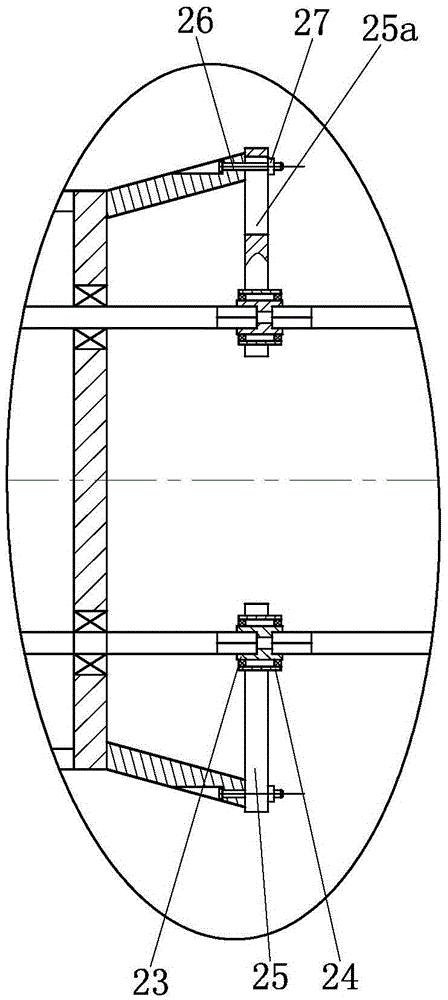

[0019] Such as figure 1 , 2 , 3, a kind of automobile exhaust manifold small head end drilling tool, mainly consists of a horizontal base plate 1, a mounting seat 2, a transmission box 3, a driving cylinder 4, a motor 5, a transmission belt 6, a transmission shaft 7, and a connection box 8 , horizontal connecting column 9, driving bull gear 10, driven pinion 11, drive shaft 12, drill bit 13 and conical connecting bucket 14 etc. constitute. Wherein, the horizontal bottom plate 1 is a rectangular plate, and the horizontal bottom plate 1 is fixed on the base by T-shaped bolts. A mounting base 2 is fixed on the left side of the horizontal base plate 1, and a transmission box 3 is arranged on the top surface of the mounting base 2. It can move left and right along the guide rail 2a. A push cylinder 4 is horizontally installed on the mounting seat 2 on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com