Automatic feeding mechanism

A technology of automatic feeding and feeding board, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high production cost and complex structure of the feeding mechanism, and achieve the effects of low production cost, easy manufacture and anti-skid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

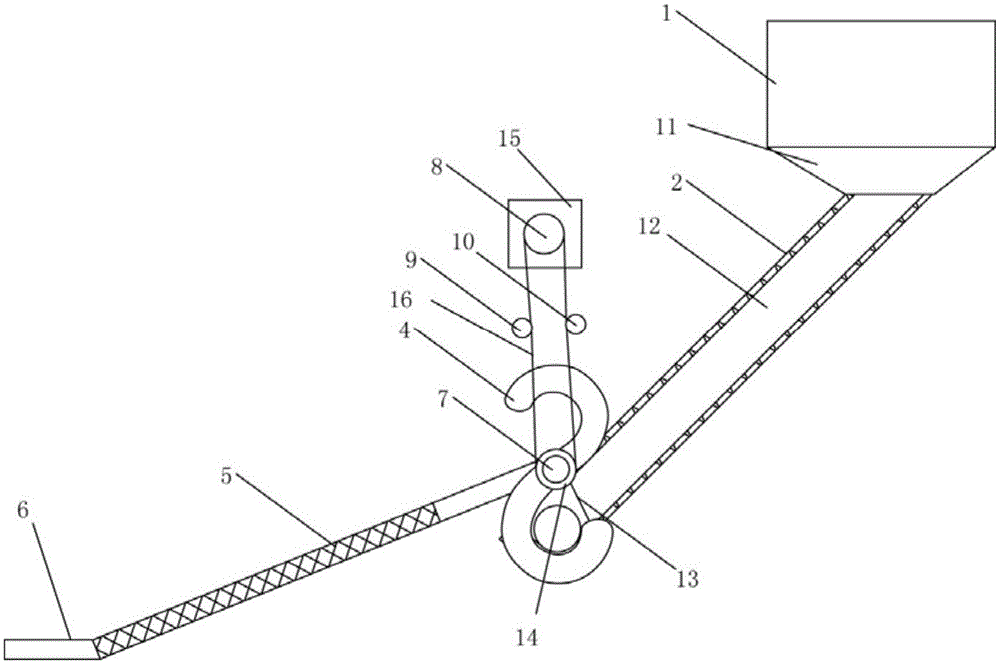

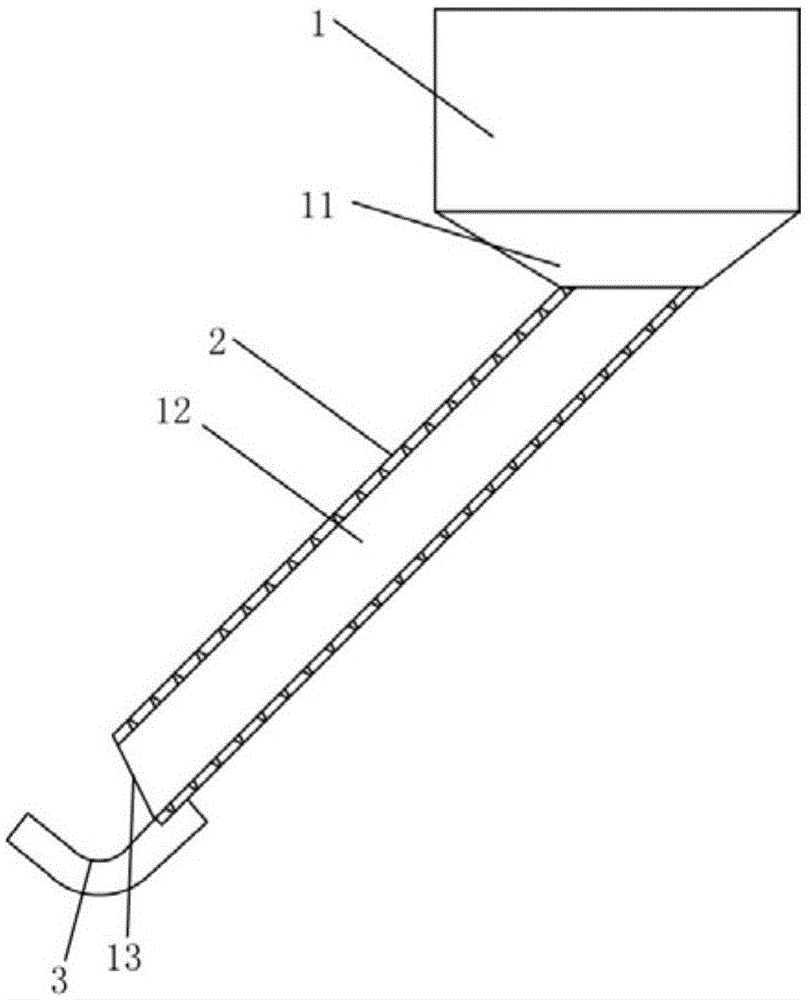

[0020] Such as Figure 1-2 As shown, an automatic feeding mechanism includes a storage box 1, a feeding guide box 2, a material blocking plate 3, a feeding plate 4, an inclined plate 5, a horizontal plate 6, a first runner 7, a second runner 8, The first pressure roller 9, the second pressure roller 10, the motor 15, the bottom of the material storage box 1 is equipped with a material storage box outlet 11, the material delivery guide box 2 is inclined, and the inside of the material delivery guide box 2 is provided with a material delivery Channel 12, the lower end of the material delivery guide box 2 is provided with a material delivery guide box outlet 13, the upper end of the material delivery channel 12 communicates with the material storage box outlet 11 and its lower end communicates with the material delivery guide box outlet 13, The blocking plate 3 is arc-shaped and is installed at the end of the discharge port 13 of the feeding guide box. The feeding plate 4 is S-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com