Method for preparing and constructing primer of waterproof coating and primer of waterproof coating

A waterproof coating film and waterproof coating technology, which is applied in the field of materials, can solve the problems of low surface strength, detachment of waterproof coating from concrete base, hindering the bonding of waterproof coating and concrete base, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The waterproof film primer is composed of A component, B component and C component;

[0069] Described A component is epoxy resin E51, and described epoxy resin E51 is 15kg;

[0070] The B component is Mannich modified diethylenetriamine with emulsifying function, and the Mannich modified diethylenetriamine is 25kg;

[0071] Described C component is water, and described water is 50kg.

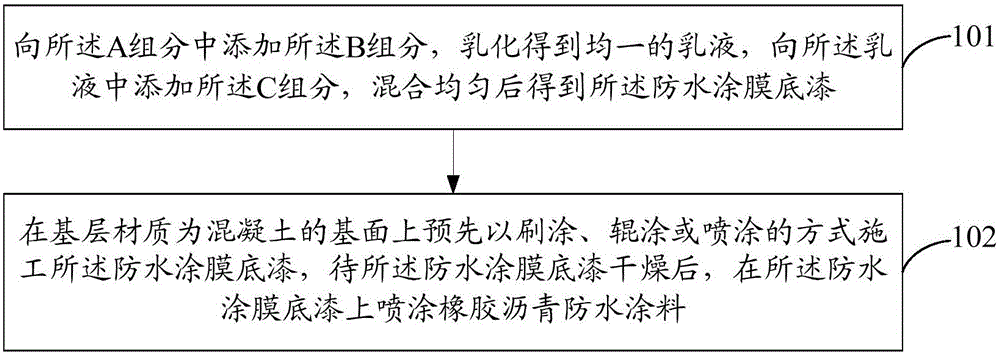

[0072] 15kg of the epoxy resin E51 and 25kg of the Mannich modified diethylenetriamine were mixed, and stirred for 3min at a speed of 500r / min with a mechanical stirrer, so that the Mannich modified diethylenetriamine curing agent Fully emulsify the epoxy resin E51 to obtain a uniform emulsion, then add 50 kg of the water to the uniform emulsion according to the formula, and stir for 2 minutes at a speed of 400 r / min with a mechanical mixer to obtain a uniform waterproof coating. Membrane primer.

[0073] On the base surface where the base material is concrete, spray 0.2kg of the wate...

Embodiment 2

[0075] The waterproof film primer is composed of A component, B component and C component;

[0076] Described A component is epoxy resin E51, and described epoxy resin E51 is 20kg;

[0077] The B component is a Mannich-modified diethylenetriamine and a Mannich-modified triethylenetetramine mixed amine curing agent with an emulsifying function, and the two mixed amine curing agents are 30kg;

[0078] Described C component is water, and described water is 60kg.

[0079] 20kg described epoxy resin E51 and 30kg described two mixed type amine curing agents are mixed, stir 3min at the speed of 500r / min with mechanical mixer, make described two kinds of mixed type amine curing agents to epoxy resin E51 was fully emulsified to obtain a uniform emulsion, and then 60kg of the water was added to the uniform emulsion according to the formula amount, and stirred at a speed of 400r / min for 2min with a mechanical stirrer to obtain a uniform waterproof coating primer.

[0080] On the base s...

Embodiment 3

[0082] The waterproof film primer is composed of A component, B component and C component;

[0083] Described A component is epoxy resin E51, and described epoxy resin E51 is 17.5kg;

[0084] The B component is Mannich modified triethylenetetramine and isophorone diamine two mixed amine curing agents with emulsifying function, and the two mixed amine curing agents are 27.5kg;

[0085] Described C component is water, and described water is 55kg.

[0086] Mix 17.5kg of the epoxy resin E51 and 27.5kg of the two mixed-type amine curing agents, and stir for 3min at a speed of 500r / min with a mechanical stirrer, so that the two kinds of mixed-type amine curing agents Oxygen resin E51 is fully emulsified to obtain a uniform emulsion, then add 55kg of the water to the uniform emulsion according to the formula, and stir for 2min at a speed of 400r / min with a mechanical mixer to obtain a uniform waterproof coating. paint.

[0087] On the base surface where the base material is concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com