Lifting and pressing pin control device of sewing machine

A control device and presser foot lifting technology, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of labor-saving manual operation of the presser foot lifter, and achieve the effect of increasing work efficiency, reducing labor intensity, and simple work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

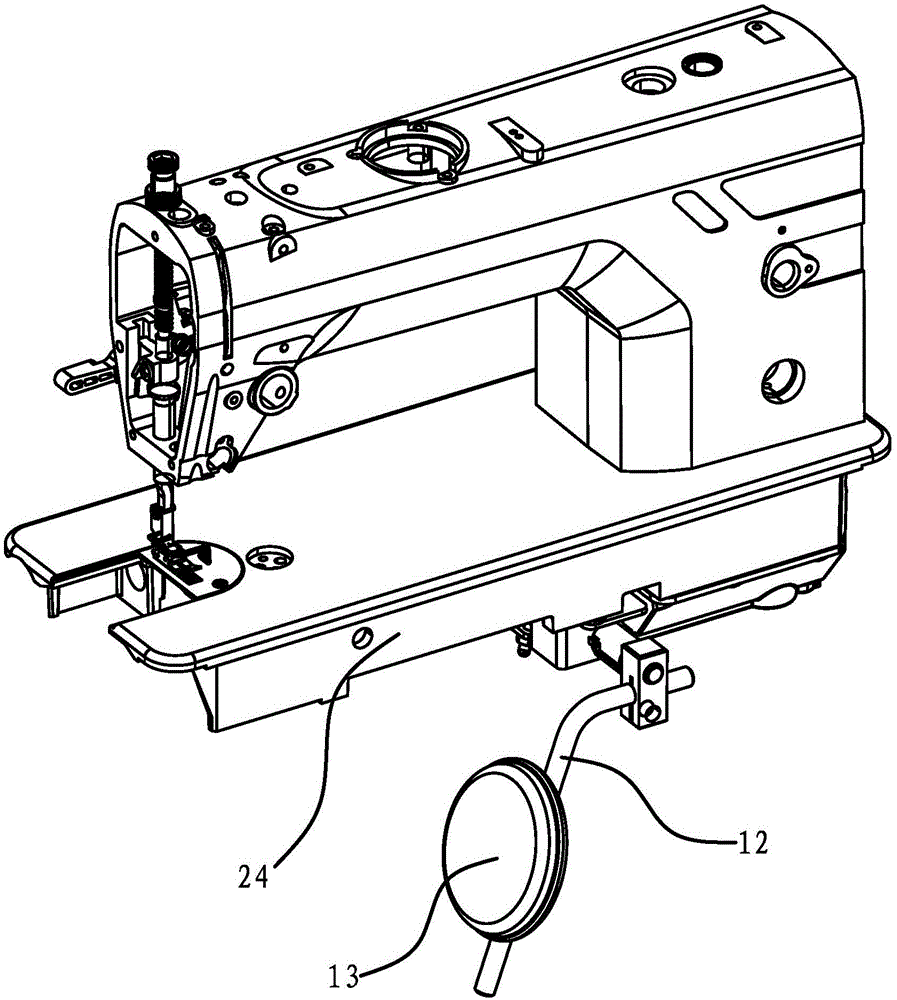

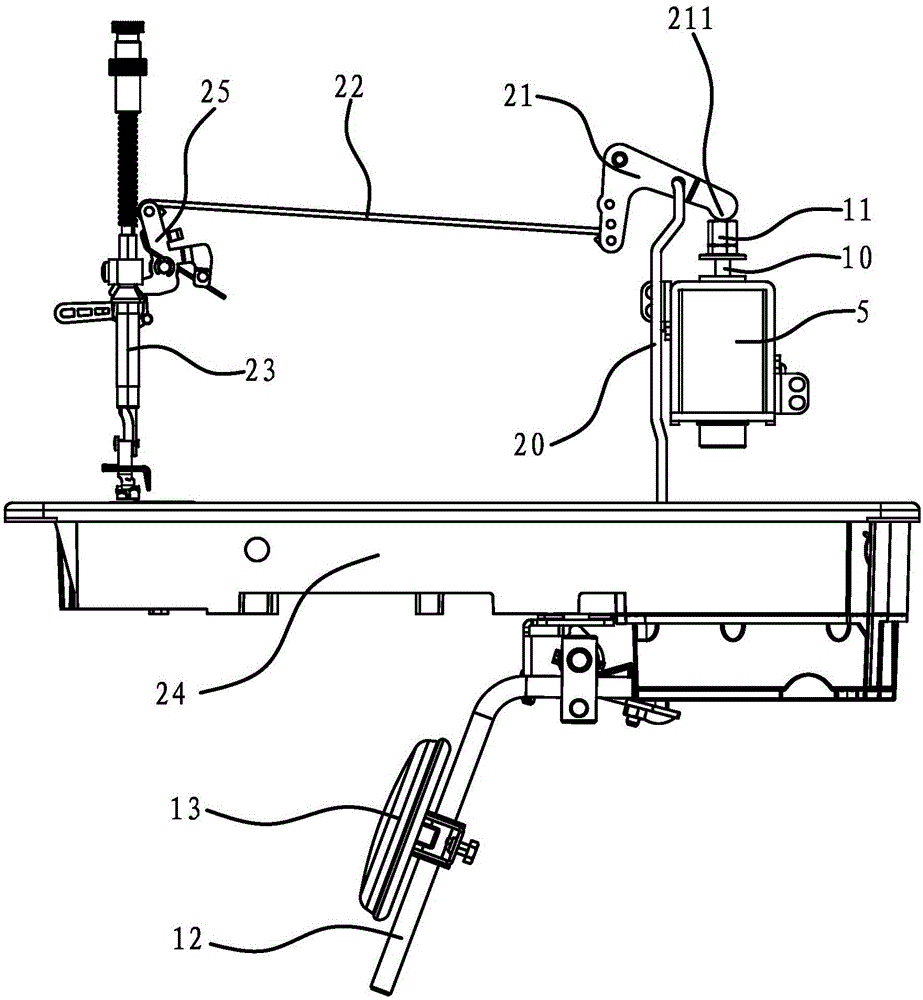

[0031] Such as Figures 2 to 5 As shown, the sewing machine includes a presser foot 23, a rear lever 21, a manipulator for manually lifting the presser foot 23 and an electromagnet 5 for automatically lifting the presser foot 23, and the manipulator and electromagnet 5 can drive the rear lever 21 to make the presser foot 23 moves. Back lever 21 connects presser foot 23 by pull bar 22 and front lever 25, and pull bar 22 one end connects back lever 21, and the other end connects front lever 25, and front lever 25 connects presser foot 23.

[0032] The electromagnet 5 has a telescopic push rod 10 up and down, the upper end of the push rod 10 is screwed with a push nut 11, the upper end surface of the push nut 11 is a straight and smooth push surface, and the rear end of the rear lever 21 has The abutting portion 211 protrudes downward in an arc shape, and the abutting portion 211 of the rear lever 21 abuts against the pushing surface of the pushing nut 11 .

[0033] The preferr...

Embodiment 2

[0052] The structure and working process in this embodiment are basically the same as those in Embodiment 1, the difference in structure is that the sensor 2 is a position sensor.

[0053] Its working process is different in that:

[0054]The position sensor is used to detect the amount of change in the position of the manipulator and send the signal to the controller 1, and the controller 1 outputs a corresponding control signal to the electromagnet control circuit according to the signal sent by the position sensor, and the electromagnet control circuit controls the operation of the electromagnet 5, Working power is less than the power of electromagnet 5 when automatic presser foot lifter 23 works.

[0055] When the operator manually lifts the presser foot with his knee against the control panel 13, the sensor 2 detects the position change of the control panel 13 and can obtain the position change of the control panel 13, and send the detected position of the control panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com