Test system and test method for real-time detection of cement content in cement mixing pile pile body

A cement mixing pile, real-time detection technology, applied in the field of underground engineering, can solve the problems of infrastructure safety hazards, long cycle, cutting corners, etc., to achieve the effect of avoiding cutting corners, short time period, and good supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention. Ordinal numbers such as "first", "second", "third", etc., used in the claims and the specification, are used to modify a claim term and not by themselves implying any priority, prior or order of a claim The chronological order in which a method step is performed before another claim is used only as a label to distinguish, for example, an element of a claim bearing a certain name from another element bearing the same name (rather than a term used for order).

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

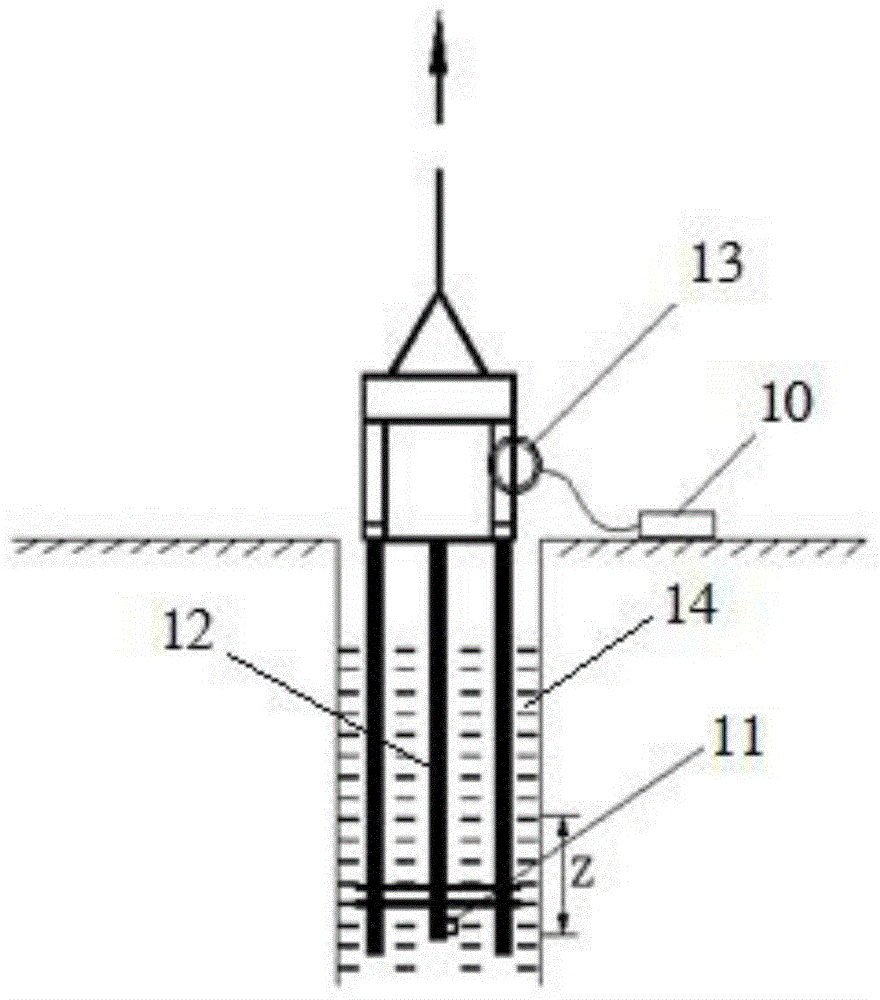

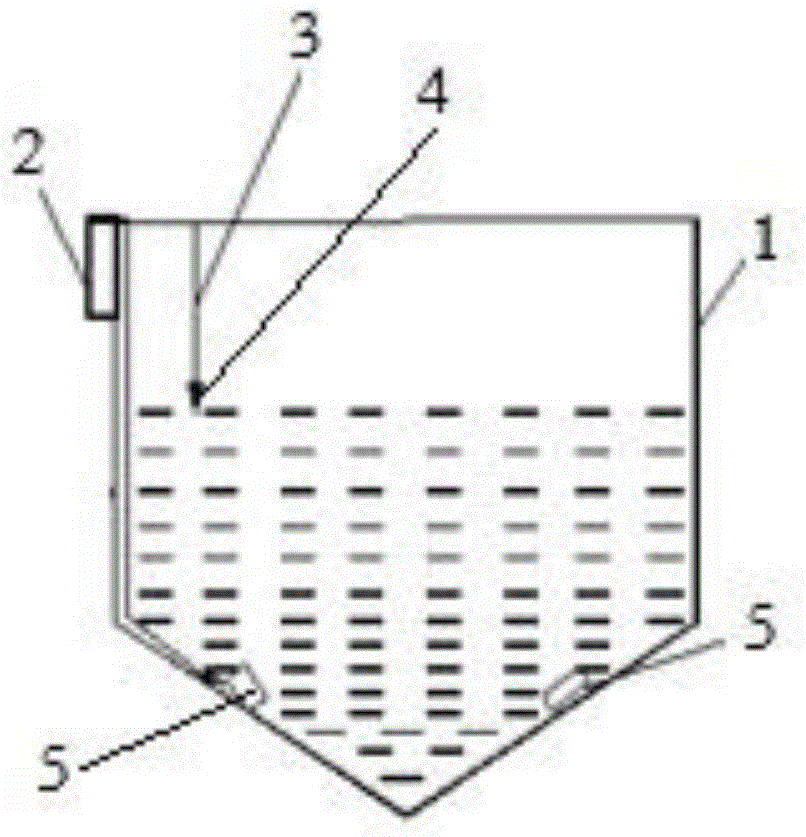

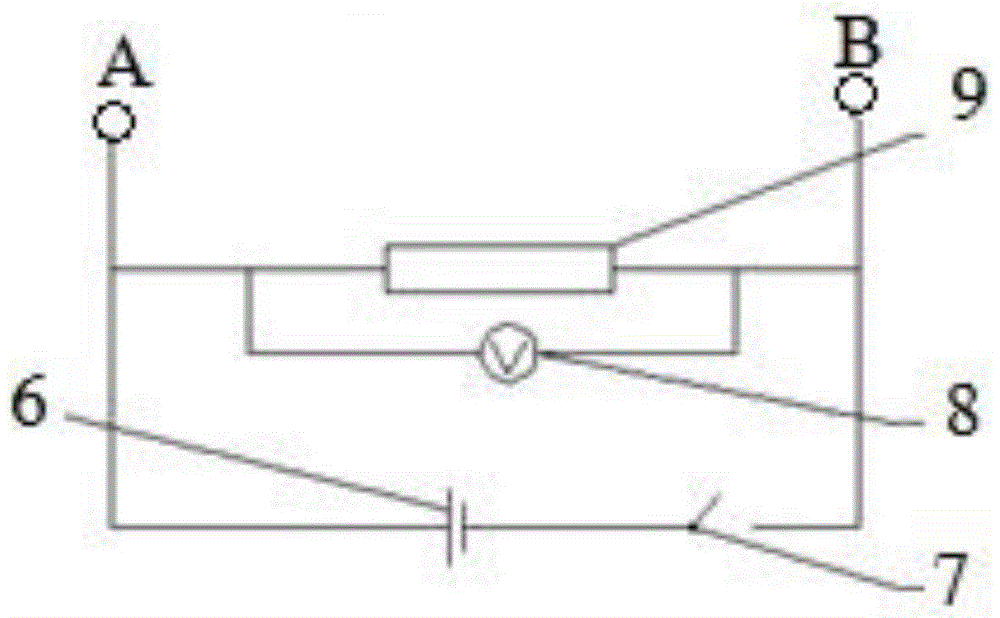

[0027] see figure 1 with figure 2 , the present invention first discloses a test system for real-time detection of cement content in the cement mixing pile body 14, the test system specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com