A prestressed steel carbon composite member

A strip steel and carbon composite technology, applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of cumbersome construction and complex structure, and achieve the effect of fast construction, simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

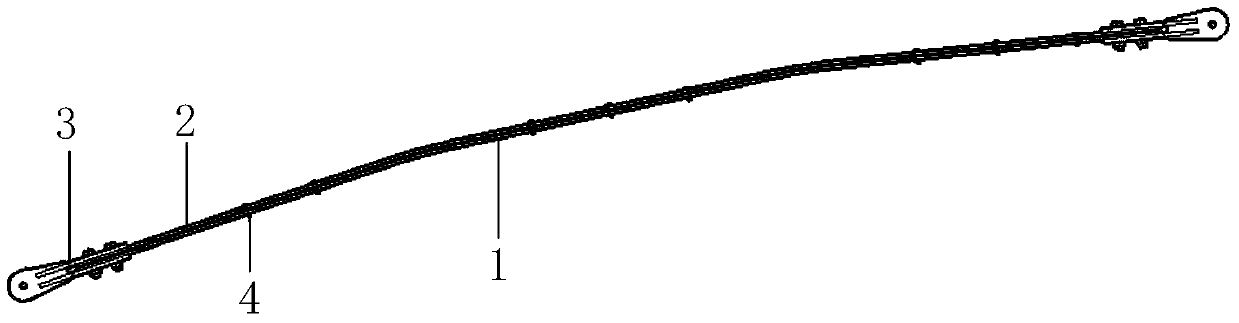

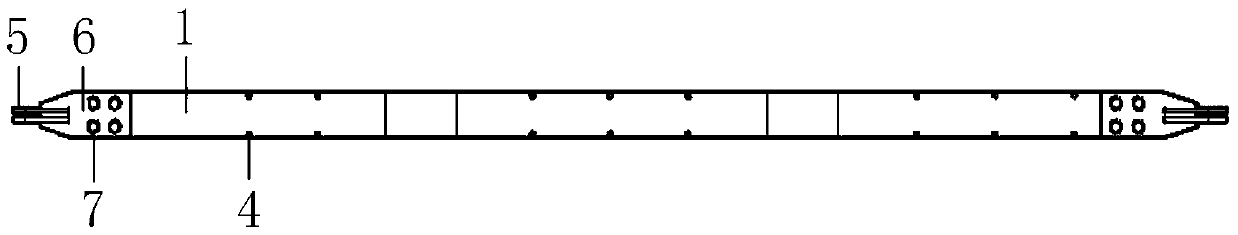

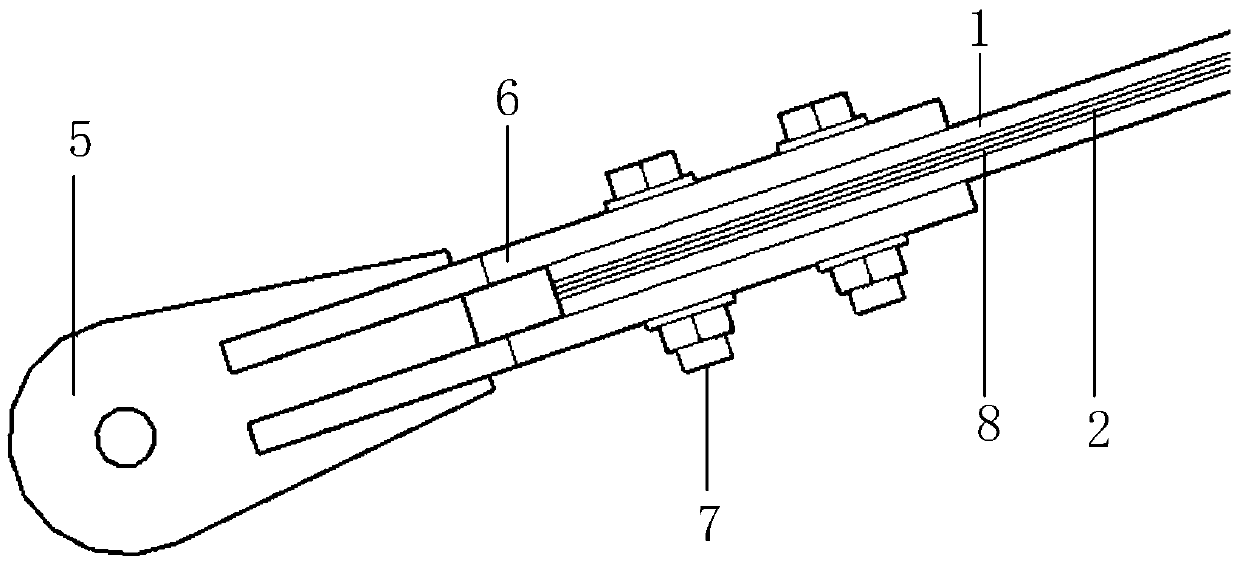

[0020] Such as Figure 1-4 As shown, a prestressed strip-shaped steel-carbon composite component includes a strip-shaped steel drawing plate 1, a strip-shaped carbon fiber plate 2, end nodes 3 and distribution bolts 4, and the strip-shaped steel drawing plate 1 is a high-strength hot-rolled steel plate The belt is stacked up and down in two layers, and a strip carbon fiber plate 2 is sandwiched between the two layers of strip steel tie plates 1. The distribution bolts 4 are two rows, distributed at intervals along the length direction of the strip steel tie plate 1, and passing through The bolt holes reserved on both sides of the strip-shaped steel tie plate 1 are fastened to the layered member; the length of the strip-shaped carbon fiber plate 2 is the same as that of the strip-shaped steel tie plate 1, and the width is between two rows of distributed bolts 4 distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com