Double-region sandwich-layer box water-cooling dynamic-balance hypocycloid reduction box

A technology of hypocycloid and reduction box, applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of reduction in thermal power of the reducer, inconvenient refueling, oil film damage, etc., to prevent oil leakage, simple structure, Ensure a balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0013] [Technical solution] The technical implementation plan is as follows:

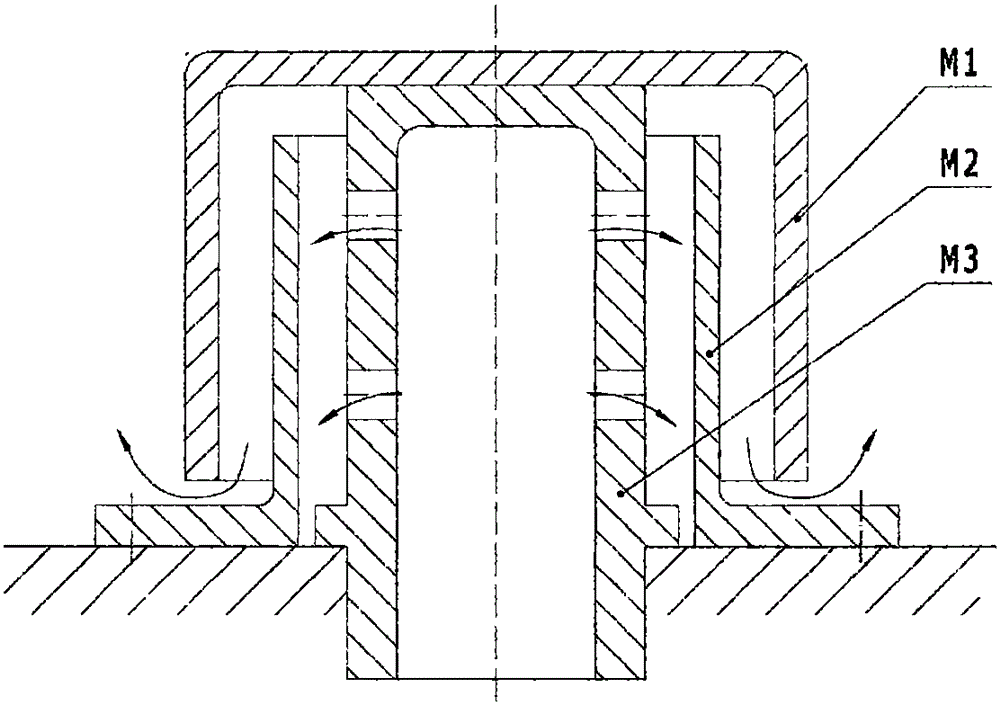

[0014] (Technical solution 1) The inner cylinder is a double-zone thin-walled cylinder, including an engaging area and a non-engaging area. The engaging area is loaded from the input end of the machine base, and the flange ring of the engaging area is connected with the inner flange ring of the machine base. The outer diameter is smaller than the outer diameter of the non-meshing area, and the outer diameter of the non-meshing area is equal to twice the height of the center of the gearbox. The non-meshing area is placed outside the machine base, and the circular wall of the non-meshing area is connected to the outer flange of the machine base. , the inner surface of the machine base and the outer surface of the meshing area are surrounded to form a closed interlayer, the top of the machine base is provided with a water inlet, and the bottom or side of the machine base is provided with a water outlet;...

specific Embodiment approach

[0025] [Specific embodiments] The present invention will be described in detail below in conjunction with the accompanying drawings:

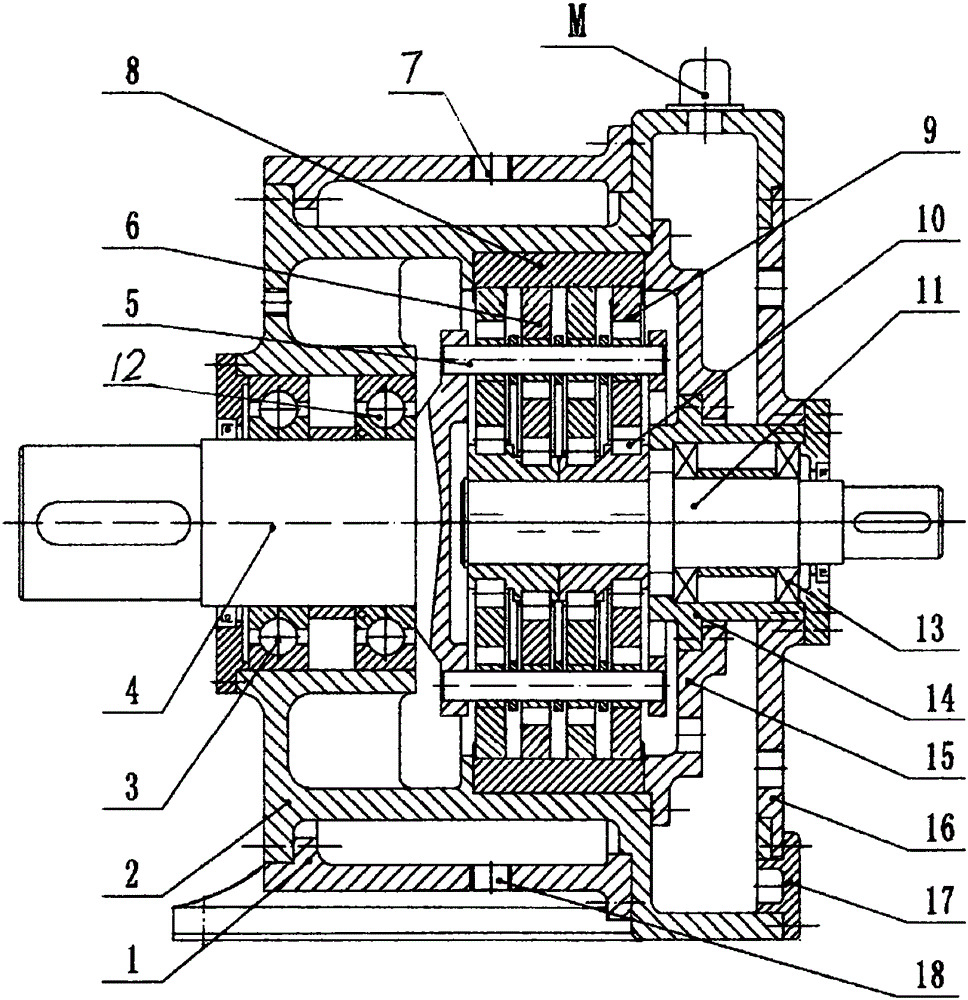

[0026] refer to figure 1 and 2 . A dual-zone interlayer box water-cooled dynamic balance hypocycloidal reducer, including a machine base 1, an inner cylinder and transmission parts in the inner cylinder, the transmission parts include an input shaft 11, an output shaft 4, a cycloidal wheel, Hypocycloid ring gear 8, column pin 5 and eccentric bearing 10, the input shaft 11 is supported by the first bearing 13 in the inner hole of the small cylinder 14, and the small cylinder 14 is connected to the inner end cover 15, its characteristic in:

[0027] The inner cylinder is a double-zone thin-walled cylinder 2, including an engaging area and a non-engaging area. The engaging area is loaded from the input end of the machine base 1, and the flange ring of the engaging area is connected with the inner flange ring of the machine base 1. The outer dia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap