Gas turbine combustion system online monitoring method based on exhaust temperature measuring point correlation

A combustion system and correlation technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as inability to realize early warning of combustion systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

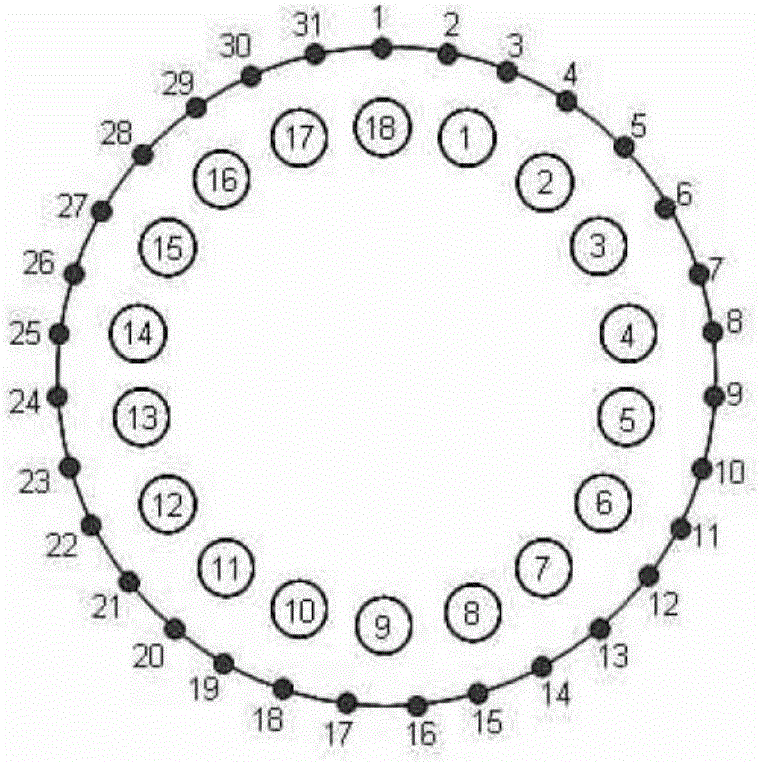

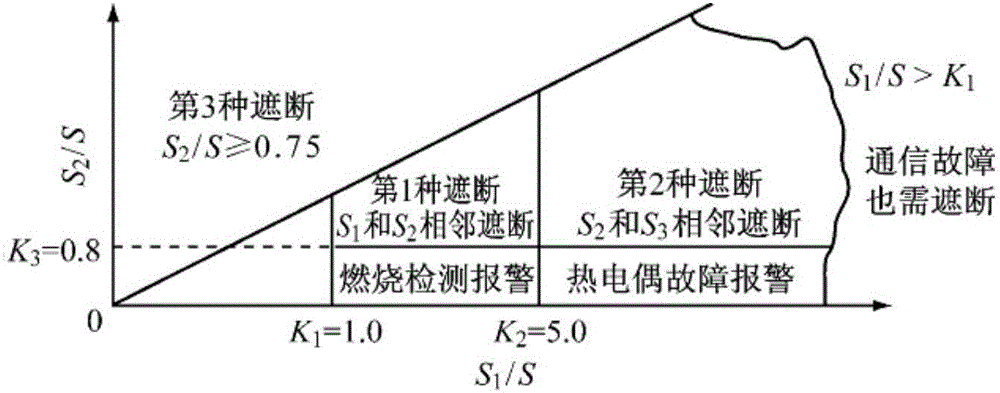

[0035] Specific implementation mode 1: An online monitoring method of gas turbine combustion system based on the correlation of exhaust temperature measurement points in this implementation mode is specifically implemented according to the following steps:

[0036] Step 1. Arrange n temperature measuring points evenly in the circumferential direction of the exhaust end of the gas turbine, and the temperature measured by the n temperature measuring points at time t is T t1 , T t2 ,...,T tn ;

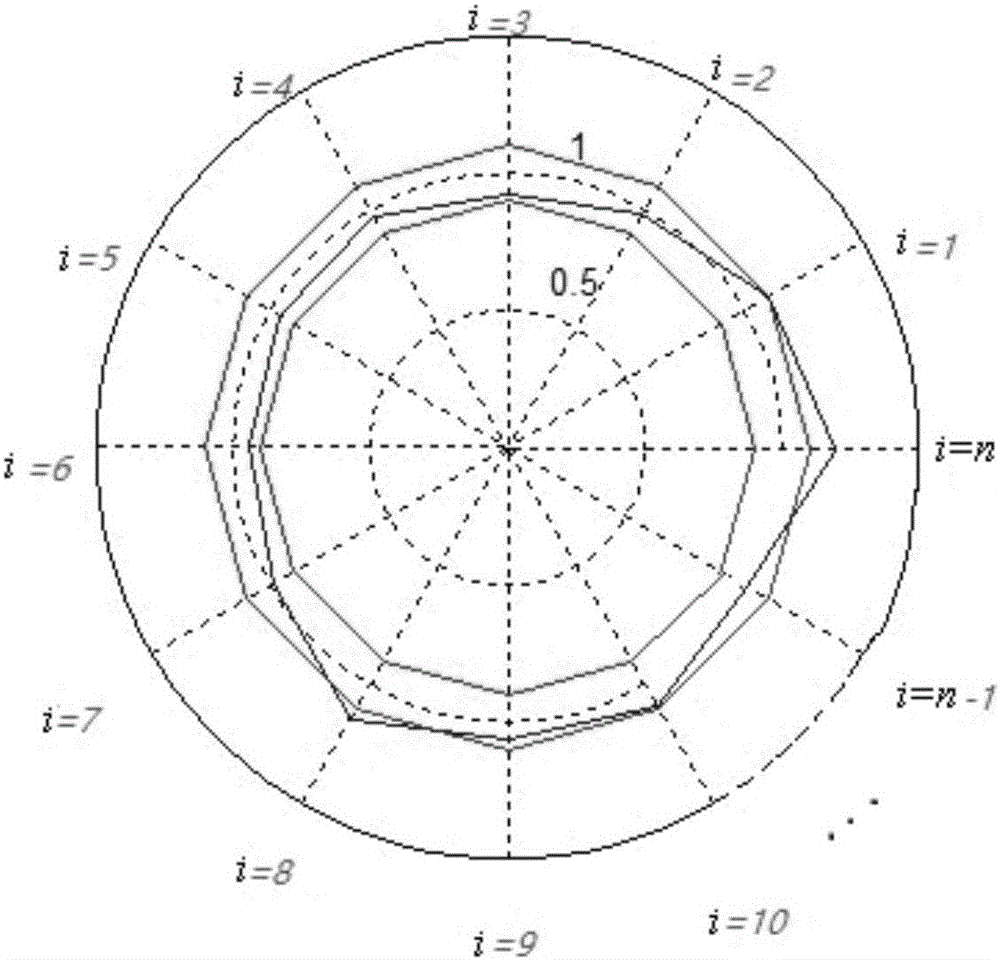

[0037] Step 2. During the period of normal operation of the gas turbine unit t 1 ~t 2 (The temperature measured at the temperature measuring point is t 1 ~t 2 The temperature at a limited number of moments, the specific number is related to the sampling frequency), according to the temperature T measured at time t by n temperature measuring points t1 , T t2 ,...,T tn , T t1 , T t2 ,...,T tn average temperature And the i-th temperature measuring point is at t 1 ~t 2 The aver...

specific Embodiment approach 2

[0057] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: in step five, α i1 =μ i -3σ i , μ i is the mathematical expectation, σ i is the standard deviation. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0058] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: in step five, α i2 =μ i +3σ i , μ i is the mathematical expectation, σ i is the standard deviation. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com