Underwater sound tester based on tunnel microscope

A microscope and tester technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of high price, complex structure of instruments and equipment, limited use occasions or application fields, etc., and achieve high precision and measurement accuracy. High and repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

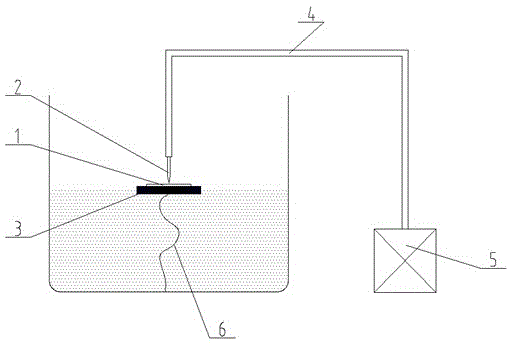

[0014] A specific embodiment of a tunnel microscope-based underwater acoustic tester according to the present invention will be described below with reference to the accompanying drawings.

[0015] Such as figure 1 As shown, an underwater acoustic tester based on a tunneling microscope includes a Z-direction nanoscale feed drive device, a tip electrode, a floating substrate, and a flat-end electrode. The floating substrate is placed on the flat end of the water surface, and the bottom of the floating substrate is provided with leads. Connected to the bottom of the water, the lead wire fixes the floating substrate, and the flat-end electrode is adhered to the surface of the floating substrate. The Z-direction nanoscale feed drive device is provided with an outer guide rod, and the end of the outer guide rod is placed above the flat-end electrode, and the tip electrode is set. At the end of the outer guide rod, the distance between the tip electrode and the flat end electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com