Constant-current-source-based high-efficiency eddy current power measuring system

A technology of constant current source and dynamometer system, applied in the field of detection system, can solve the problem of inability to collect comprehensive parameters of internal combustion engine in real time, and achieve the effect of strong data processing ability, avoiding temperature drift, and ensuring reliability and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

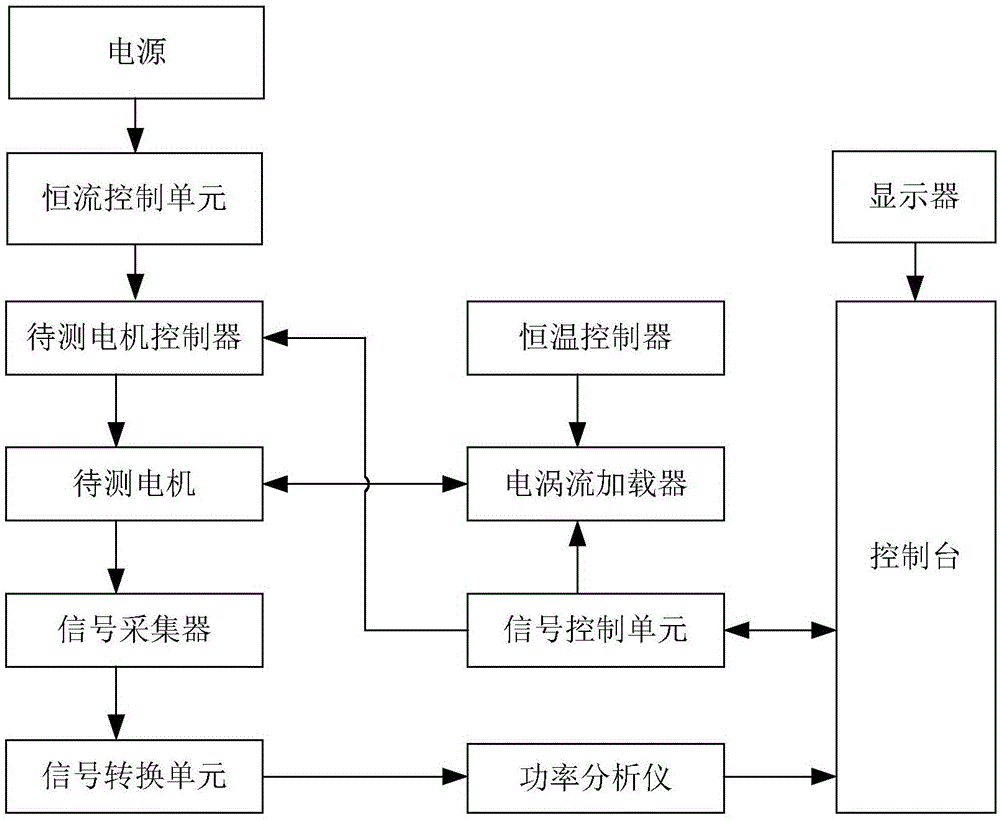

[0021] Such as figure 1 As shown, the high-efficiency eddy current dynamometer system based on a constant current source of the present invention includes a motor to be tested, a motor controller to be tested, an eddy current loader, a signal control unit, a constant temperature controller, a console, a signal collector, Signal conversion unit, constant current control unit, power supply, power analyzer and display 12 parts.

[0022] Wherein, the constant current control unit is connected with the power supply, and the power supply is used to provide working power for the system, and the constant current control unit can ensure that the system has a constant working current. The motor to be tested is connected to the constant current control unit, and the motor controller to be tested is connected to the motor to be tested to control the speed, start and stop of the motor to be tested. The eddy current loader is connected with the motor under test through a coupling, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com