A kind of plc control system and plc expansion bus realization method

A technology for expanding the bus and control system, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as poor anti-interference ability, prone to errors, and impermissibility, etc., and achieve strong anti-interference ability and high data speed The effect of improving and stabilizing data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

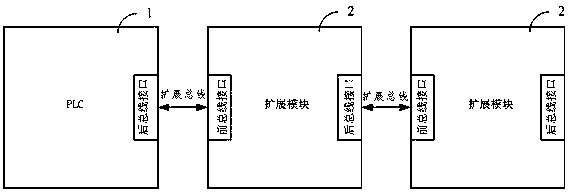

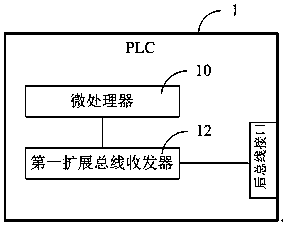

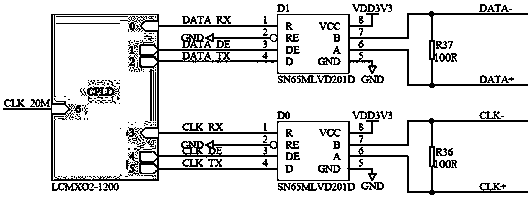

[0046] Such as figure 1 As shown in FIG. 1 , a schematic structural diagram of an embodiment of a PLC control system provided by the present invention is shown. In this embodiment, the PLC control system includes a PLC1 and a plurality of expansion modules 2, and the expansion bus is used to cascade between the PLC1 and the plurality of expansion modules 2 to form a bus topology; wherein, in one embodiment, in this In one embodiment of the invention, the expansion bus adopts MLVDS (Multipoint low Voltage Differential Signaling, multi-point low voltage differential signal) expansion bus, and the MLVDS bus belongs to the half-duplex communication of bus type topology, and the expansion bus mentioned later All are described with the MLVDS extension bus, but it should be understood that in other embodiments, other types of buses may also be used. The exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com