Method for reducing partial heating of transformer shell

A transformer and local overheating technology, applied in the direction of transformer/inductor cooling, etc., can solve the problem of reducing local heating and overheating of the transformer shell, and achieve the effect of convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

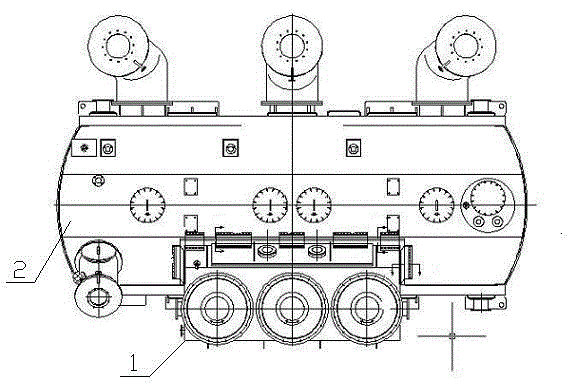

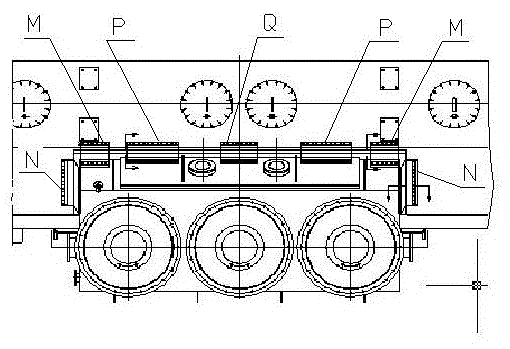

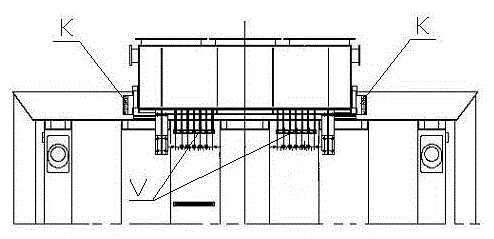

[0019] This embodiment is a method for reducing local heating of the transformer shell, see figure 1 , because limited by the internal conditions of the main transformer, it is impossible to install a magnetic shield in the low-voltage riser 1 on one side of the transformer shell 2, and the low-voltage riser 1 itself cannot be replaced. According to the current shunting principle of the parallel circuit, the branch with large resistance has small current, and the branch with small resistance has large current, leading the eddy current to the short-circuit copper bar with small resistance and non-magnetic conduction, thereby reducing the eddy current loss and making the transformer shell hot spot temperature get lowered.

[0020] Specifically, the local overheating part in the low-voltage riser 1 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com