Water path collecting pipe for internal water cooling phase-shifting transformer

A phase-shifting transformer and water cooling technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of high water supply pressure, poor reliability, temperature rise, etc., and achieve low cooling water flow resistance, good cooling effect, and low water supply pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

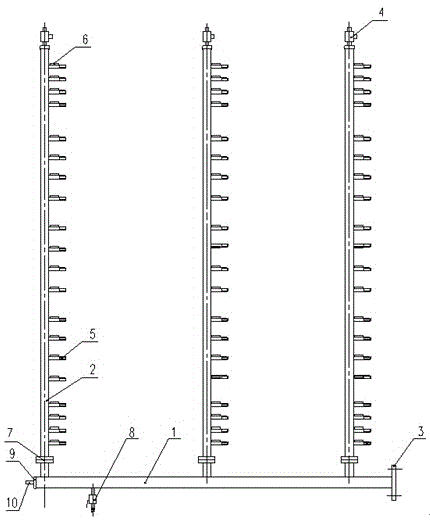

Embodiment 1

[0022] A water channel manifold for a water-internal cooling phase-shifting transformer, characterized in that it includes a manifold 1, a plurality of manifold branches 2, and a waterway joint 5; one end of the manifold branch 2 communicates with the manifold 1 through a loop flange 7 (It can also be connected by welding), the other end of the confluence branch pipe 2 is installed with a temperature and pressure safety valve (automatic exhaust valve can also be installed) 4; one end of the confluence main pipe 1 is sealed by welding end sealing plate 9, and the other end A flange 3 is provided, and a grounding bolt 10 is provided on the end sealing plate 9; multiple waterway joints 5 are welded on the confluence branch pipe 2, and a temperature measuring probe 6 is installed on the waterway joints 5; a drain valve is provided on the confluence main pipe 1 8; wherein the confluence main pipe 1, the confluence branch pipe 2 and the waterway joint 5 are made of stainless steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com