Directly-inserted power semiconductor module test clamp

A technology for power semiconductor and module testing, which is used in single semiconductor device testing, semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, etc. The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Design points of the present invention

[0015] 1) Overall structure design

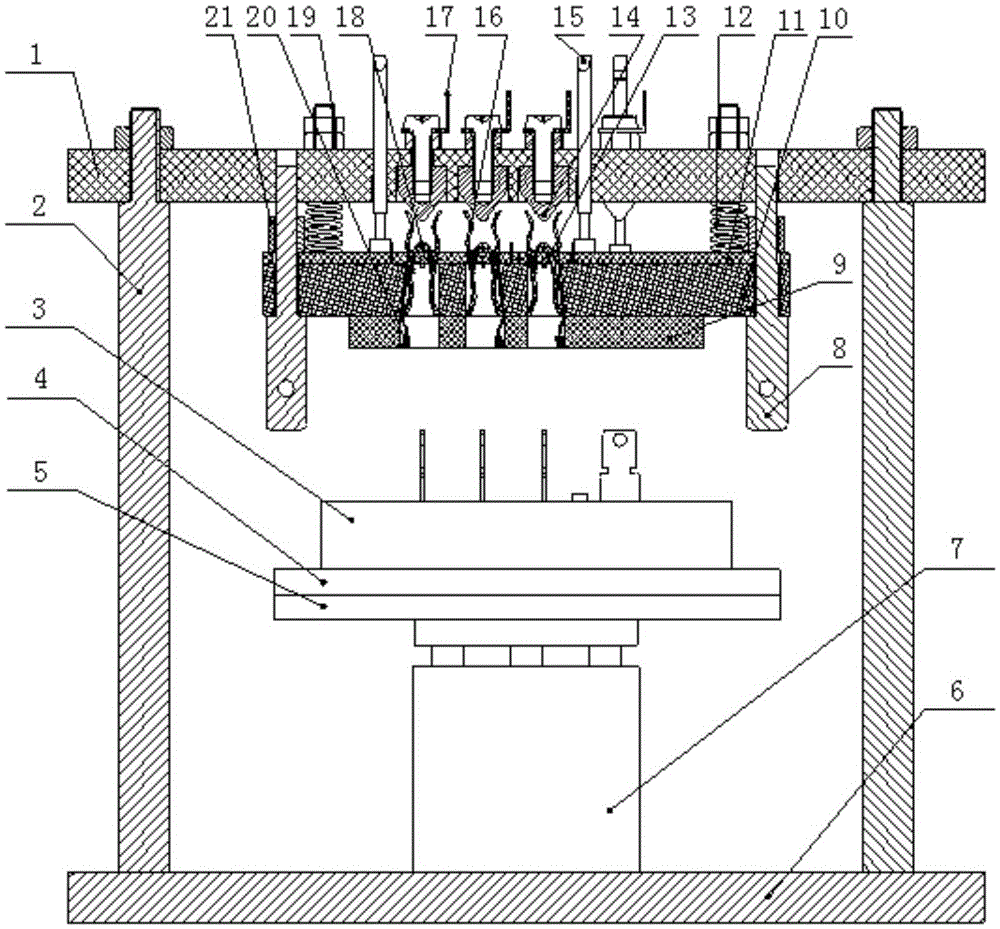

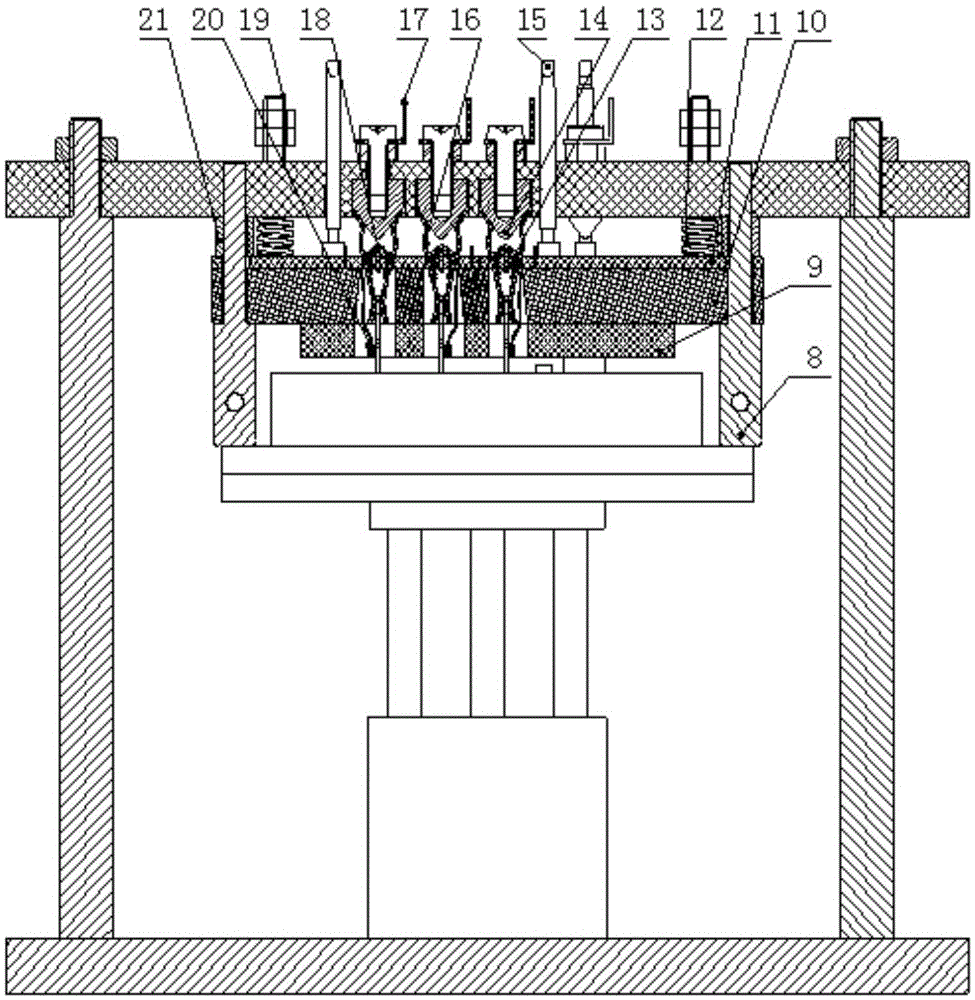

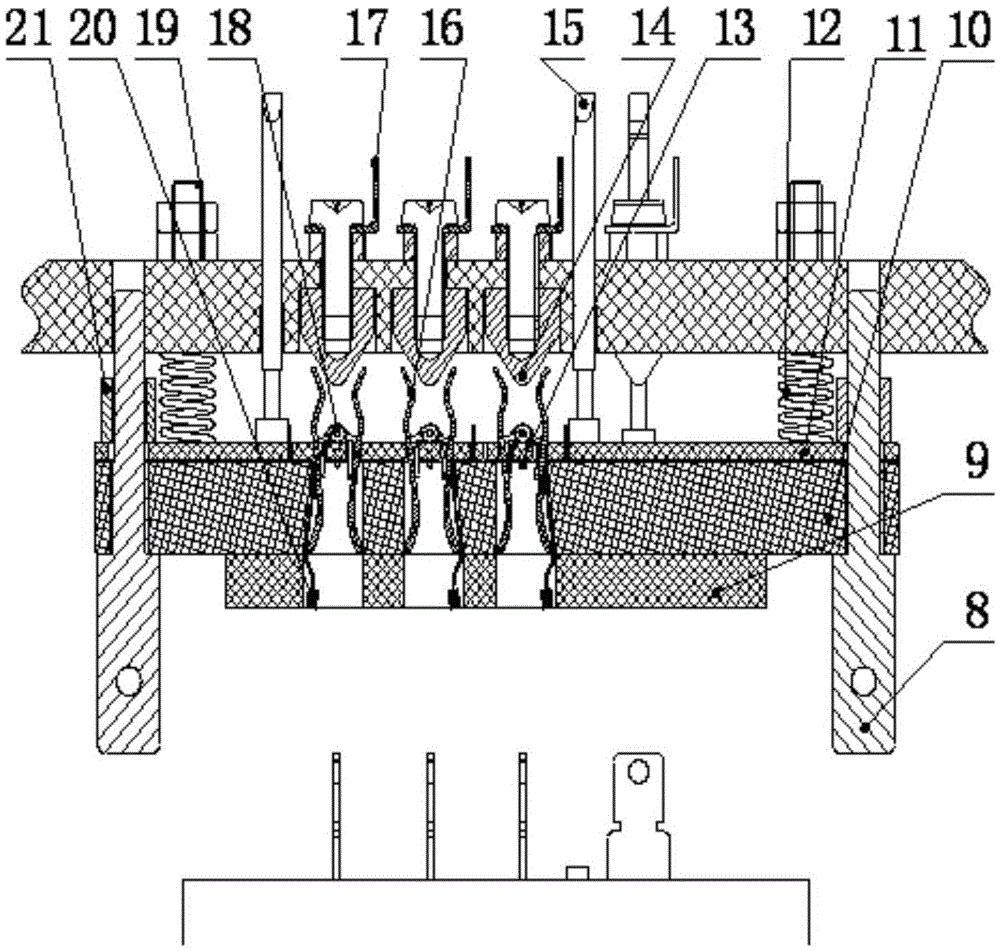

[0016] The basic overall structure of this fixture is a door-type box structure, and the main part is: upper fixed plate 1, support rod 2, bottom plate 6 and three-axis cylinder 7; two support rods 2 are fixed on the bottom plate 6, and the upper fixed plate 1 passes through The nuts are fixed on the two support rods 2 to form a portal frame structure; the three-axis cylinder 7 is installed on the bottom plate 6, and the module lifting table 5 is fixed on the three-axis cylinder 7, which is used to lift the measured module 3 to move up and down; A positioning plate 4 is installed on the module lifting platform 5, and the positioning plate 4 can be replaced according to the shape of the measured module 3 to ensure that the electrode position of the module is accurate; the entire electrode clamping and signal sampling mechanism assembly is located on the upper fixing plate 1.

[0017] 2) Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com