Engine control unit for a self-igniting internal combustion engine and method for operating a self-igniting internal combustion engine

An automatic ignition, internal combustion engine technology, applied in engine control, internal combustion piston engine, engine components, etc., can solve problems such as expensive, large number of components and control devices, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

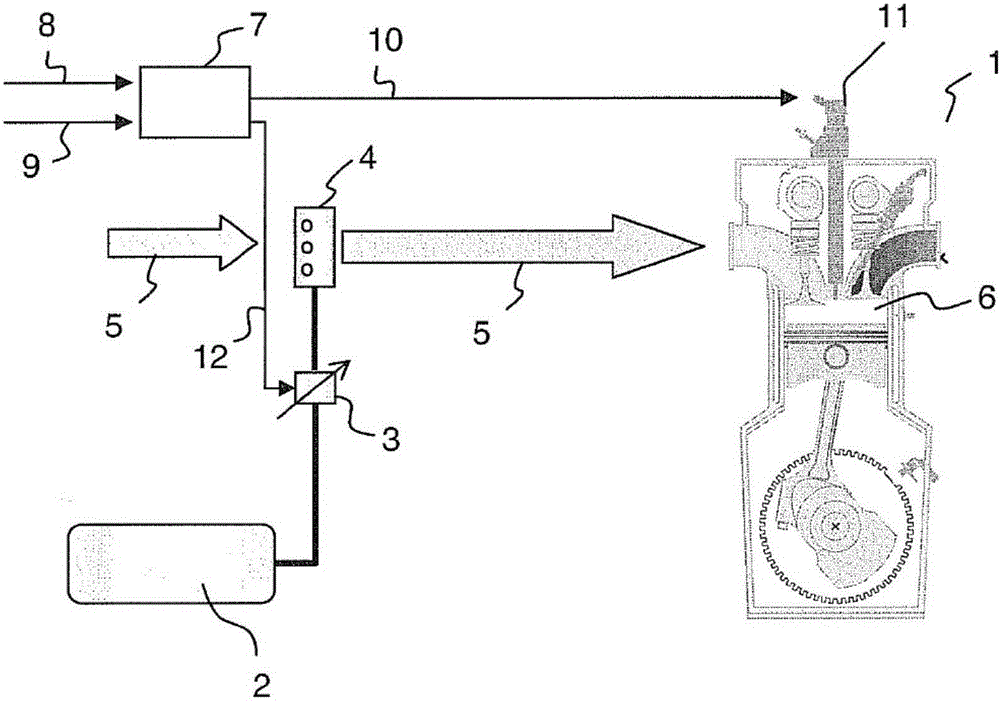

[0022] In addition to auto-ignition diesel fuel, internal combustion engines may also be used with a second non-auto-ignition fuel supply, for example comprising compressed natural gas (CNG). CNG is stored in fuel tank 2 . With the help of a pressure regulator 3 CNG can be supplied to a Venturi mixer 4 . The Venturi mixer 4 is integrated into the intake tract 5 of the internal combustion engine. Thus, combustion chamber 6 of cylinder 1 is supplied with a mixture of air, diesel fuel and CNG.

[0023] The composition of the air-fuel mixture is regulated by the engine control 7 in a closed loop or in an open control system. Like any conventional engine control device 7, this unit also includes several analog and digital input and output interfaces to sensors and brakes. In addition, a CAN bus interface (not shown) is provided on the engine control device 7 for communication with other control devices in the vehicle.

[0024] The input signals of the engine control unit 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com