Device and method for inserting magnet into rotor core magnet insertion hole

A technology of rotor iron core and insertion device, which is applied in the manufacture of stator/rotor body, electromechanical device, magnetic circuit, etc., can solve problems such as magnet pieces hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

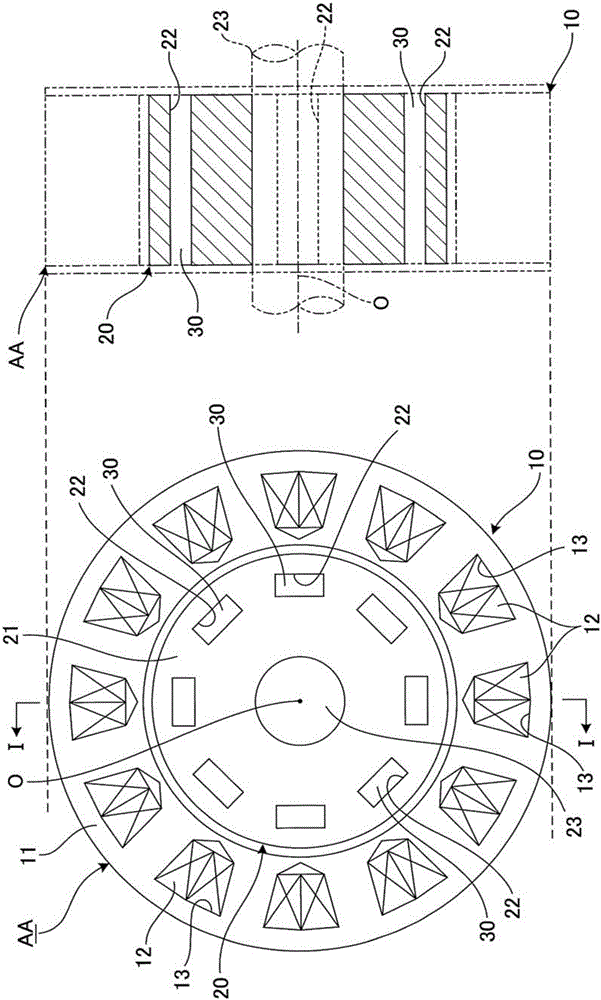

[0020] figure 1 It is a schematic configuration diagram showing the configuration of a main part of a rotating electrical machine provided with a rotor in which magnets are inserted into rotor core magnet insertion holes according to the present embodiment. exist figure 1 In , the figure on the left is a cross-sectional view of the rotating electrical machine, and the figure on the right is a side view. The rotary electric machine AA includes: an annular stator 10 constituting a part of an unillustrated casing; and a cylindrical rotor 20 arranged coaxially with the stator 10 . The rotary electric machine AA is, for example, an electric motor, and is used as a driving source of an electric vehicle or a hybrid vehicle. However, the rotating electric machine can also be a generator, and its use is not limited to automobiles.

[0021] The stator 10 includes a stator core 11 and a plurality of coils 12 . The plurality of coils 12 are accommodated in slots 13 formed at equal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com