Meat-emulsion pill forming device

A forming device and a technology of minced meat balls, which are applied in the forming and slaughtering of processed meat and food, can solve the problems of not being able to meet the living needs of the masses, and achieve the goal of getting rid of poor sanitation conditions, ensuring consistency, and being convenient for installation, disassembly and washing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

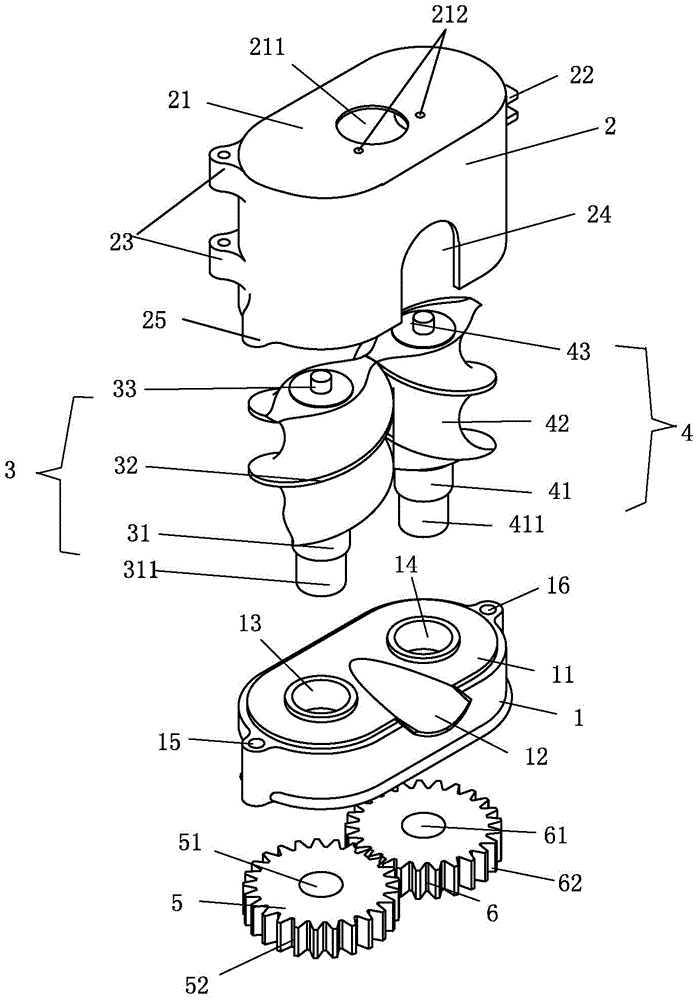

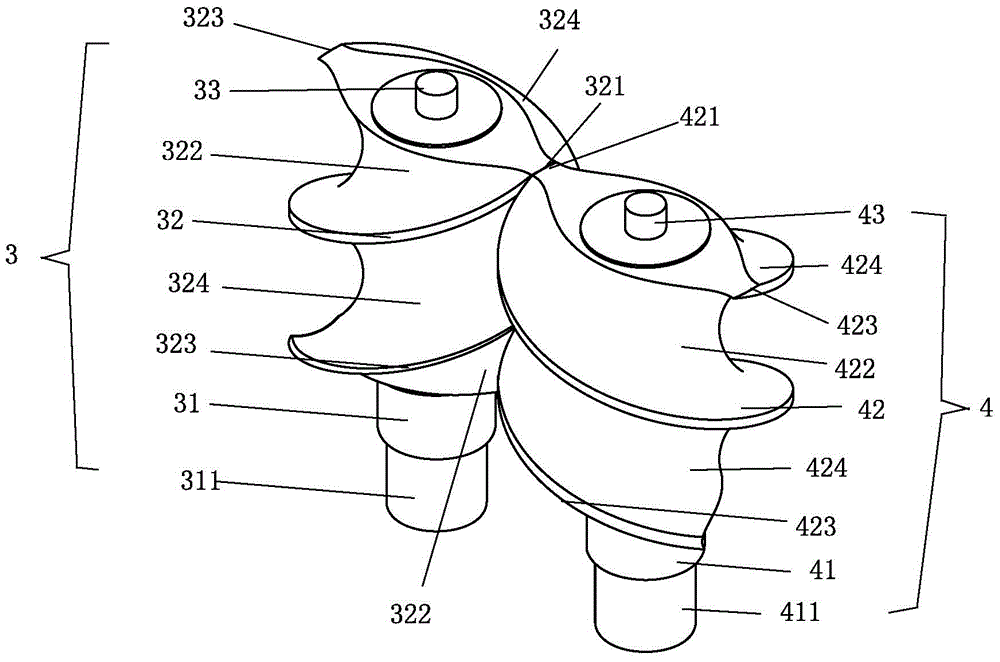

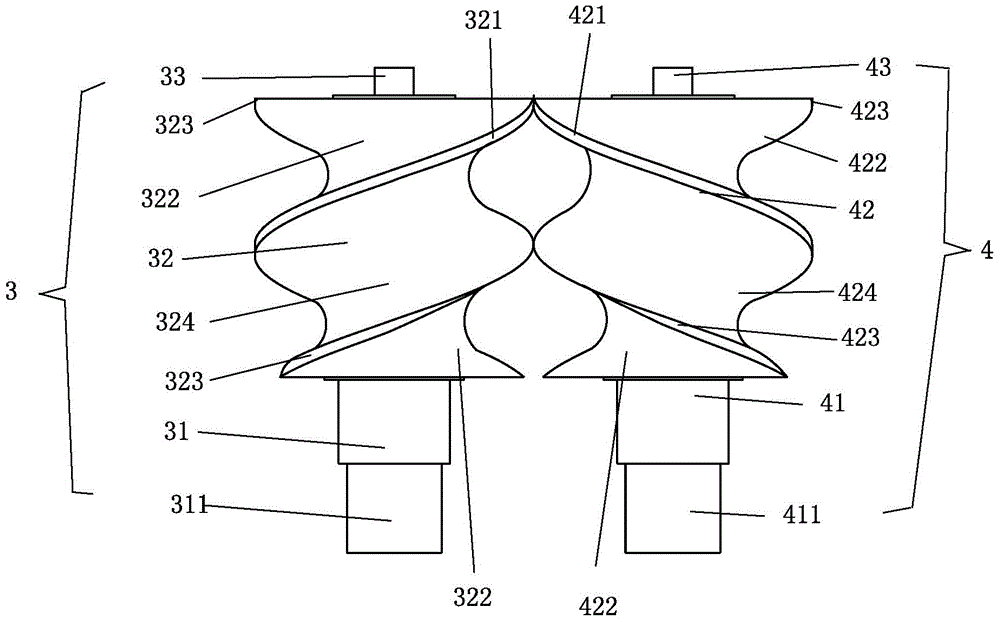

[0030] For the various components of the minced meat ball forming device of the present invention, please refer to figure 1 , it has base 1, housing 2, left cutting and pressing screw rod 3, right cutting and pressing screw rod 4, left driving gear 5 and right driving gear 6 these six main parts.

[0031] Base 1 is an oblong box with open bottom and rear side. In the middle of the flat upper wall 11 at the upper end of the base 1, there is a ball leading-out part 12 protruding forward. . The left and right sides of the upper wall 11 of the base 1 are respectively provided with a left support hole 13 and a right support hole 14 passing through the inner cavity thereof. The outer sides of the left and right ends of the vertical wall of the base 1 are respectively provided with an upright left lug 15 and a right lug 16, and the inner holes of the left lug 15 and the right lug 16 are through holes. Base 1 rear side is open abdication window 18 (seeing image 3 ).

[0032]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com