Small-caliber tube inner wall powder electrothermal explosion spraying device

A small-caliber tube and powder technology, which is applied in the direction of electrostatic spraying device, spraying device, liquid spraying equipment, etc., can solve the problems that the device cannot be extended into a longer tube for spraying, and the application range of electrothermal explosion spraying is limited, so as to simplify equipment, Guarantee the effect of stability and uniform explosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

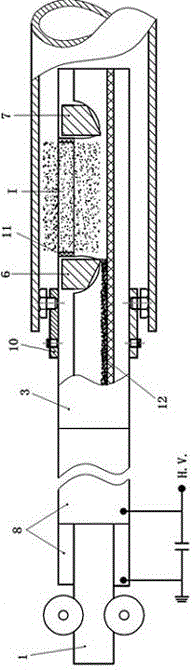

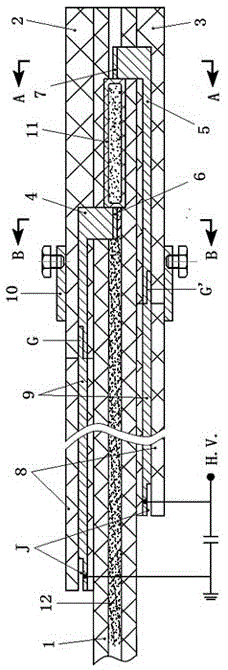

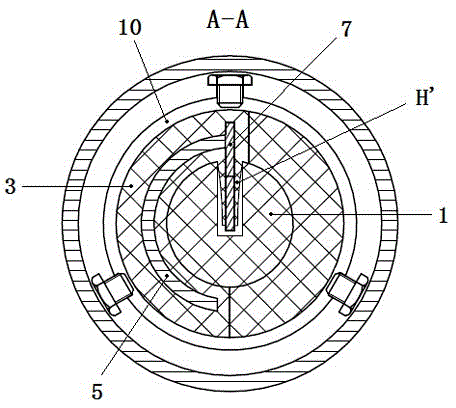

[0007] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a small-caliber pipe inner wall powder electrothermal explosion spraying device, which is composed of a conductive gun head, a low-voltage electrode 6, a high-voltage electrode 7, a conductive connector, a powder feeding pipe 1 and a support sleeve 10. The shape of the conductive gun head It is in the shape of a circular tube and is composed of a semi-circular low-voltage conductor and a semi-circular high-voltage conductor. The low-voltage electrode 6 is installed in the low-voltage conductor, and the high-voltage electrode 7 is installed in the high-voltage conductor. The low-voltage conductor is connected by a clamp connection. The conductor is tightly connected to the high-voltage conductor. The shape of the conductive connector is semicircular and coaxial with the conductive gun head. One end is connected to the conductive gun head, and the other end is connected to the two pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com