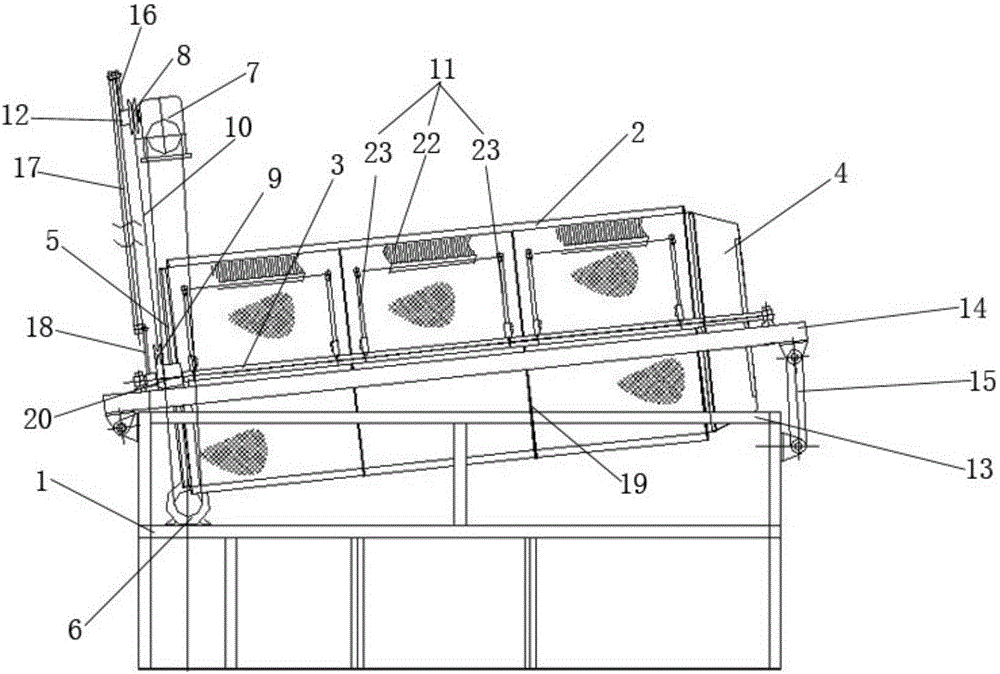

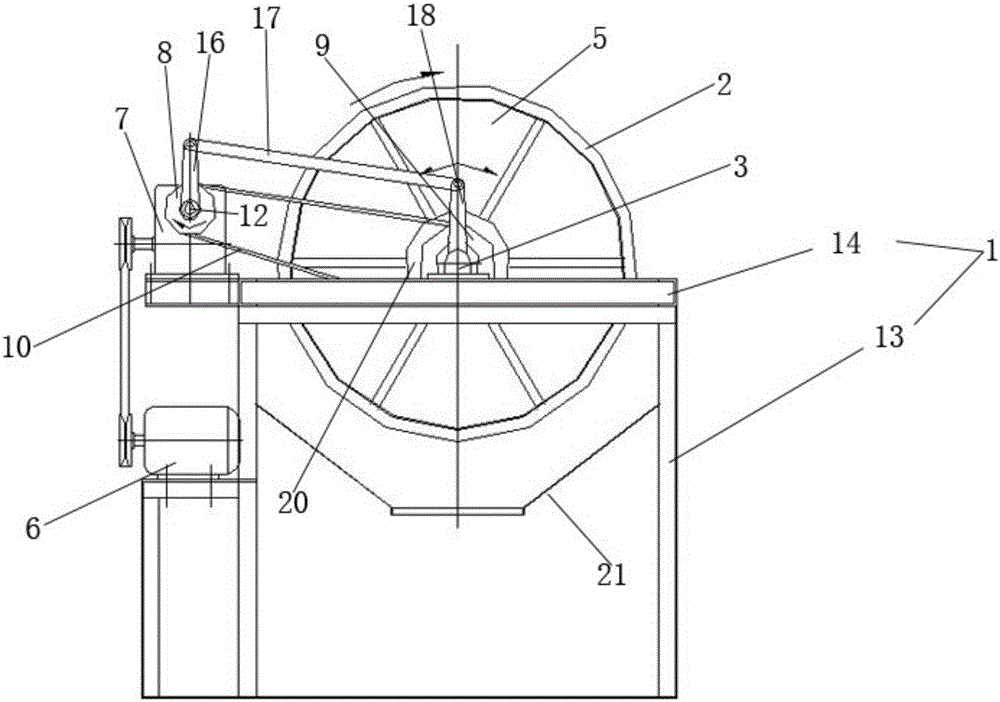

Fresh leaf sorting machine

A sorting machine, fresh leaf technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of high production and maintenance cost, easy damage, poor stability, etc., achieve high production efficiency, save equipment cost, and run smoothly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] The screen cleaning mechanism is a leaf cleaning sweep 11 horizontally arranged in the circular screen cylinder 2 to keep flexible contact with the screen. The leaf cleaning sweep 11 is fixedly connected to the rotating shaft 3 and keeps moving synchronously. The leaf cleaning sweep 11 can be connected with each classification and screening section One-to-one correspondence setting, make the length of leaf-cleaning sweep 11 match with the horizontal width of the screen cloth on each grading and screening section, so as to refine the cleaning and blocking operation of each grading and screening section, make the cleaning work more thorough, and improve the efficiency and efficiency of grading and screening. quality. As an embodiment, the leaf cleaning sweep 11 includes a flexible brush head 22 and a support rod 23, one ends of the two support rods 23 are respectively connected to the two ends of the flexible brush head 22, and the other ends of the two support rods 23 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com