Multi-station full-automatic feeding device

A feeding device and fully automatic technology, which is applied in the field of multi-station automatic feeding devices, can solve problems such as affecting the quality of die-casting products, spilling molten liquid in the spoon, and being prone to safety accidents, so as to increase the traveling speed and operation. Stability, avoid melt splash, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

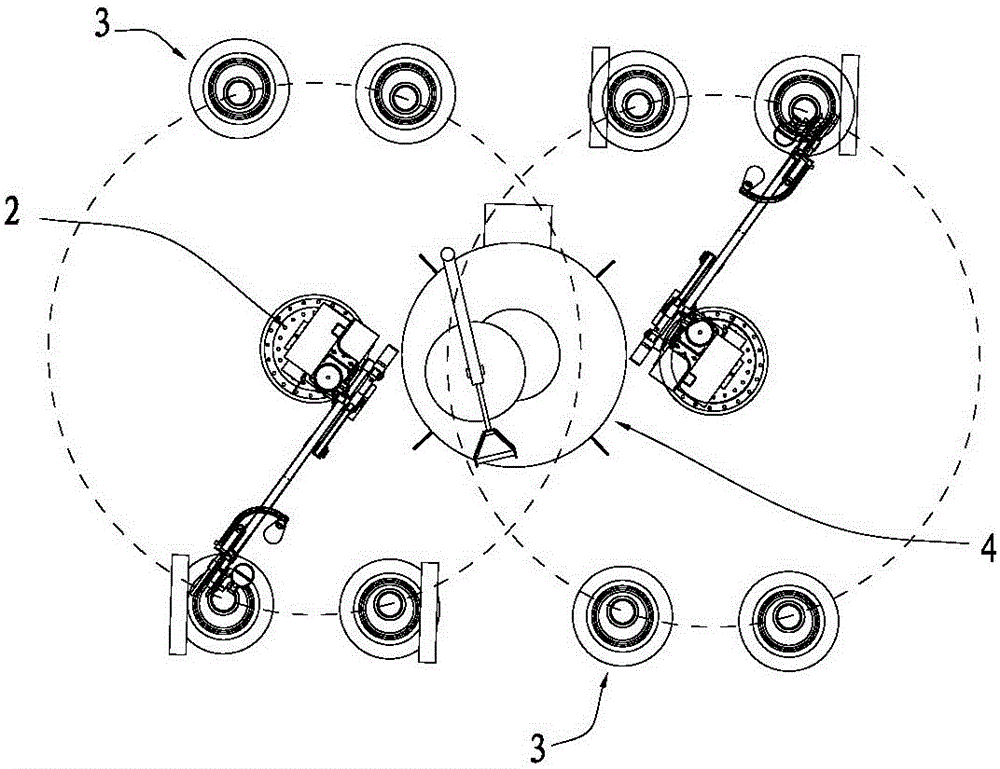

[0017] see figure 1 , a multi-station fully automatic feeding device provided in this embodiment, which includes a rotary table 1, a soup feeder 2, a bin body 3 and a furnace 4, the rotary table 1 is arranged on one side of the furnace 4, A plurality of bins 3 are distributed on the periphery of the turntable 1 , and the soup dispenser 2 is set on the turntable 1 , and can scoop up the melt in the furnace 4 and pour it into the bins 3 . in figure 1 The dotted line in is the soup feeding rotation track line of the soup feeding machine 2. In this embodiment, preferably, there are two soup dispensers 2 , each of which is symmetrically arranged on both sides of the melting furnace 4 through a rotating table 1 .

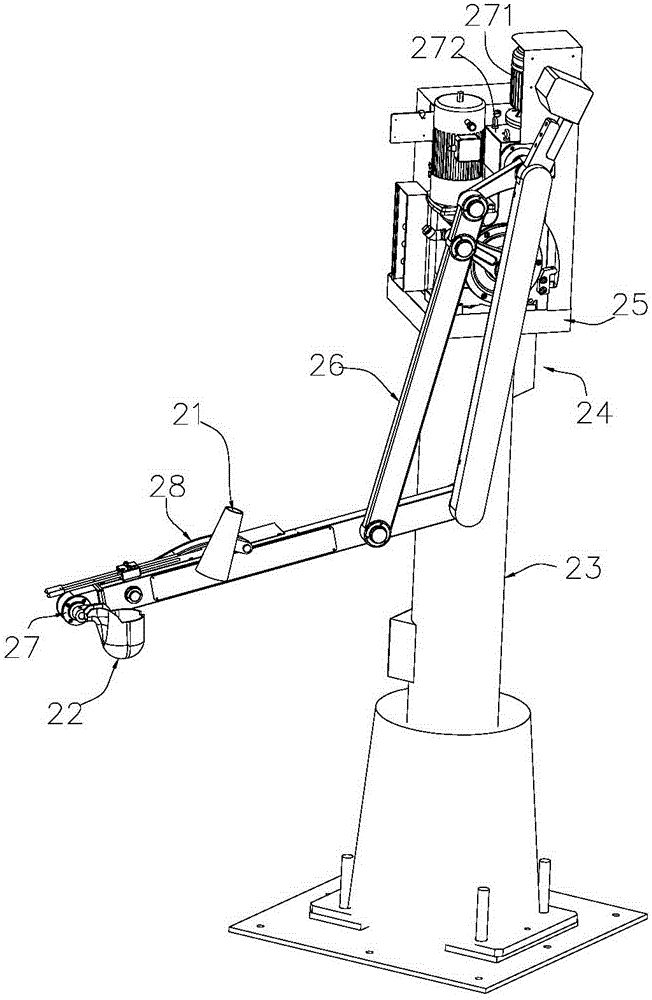

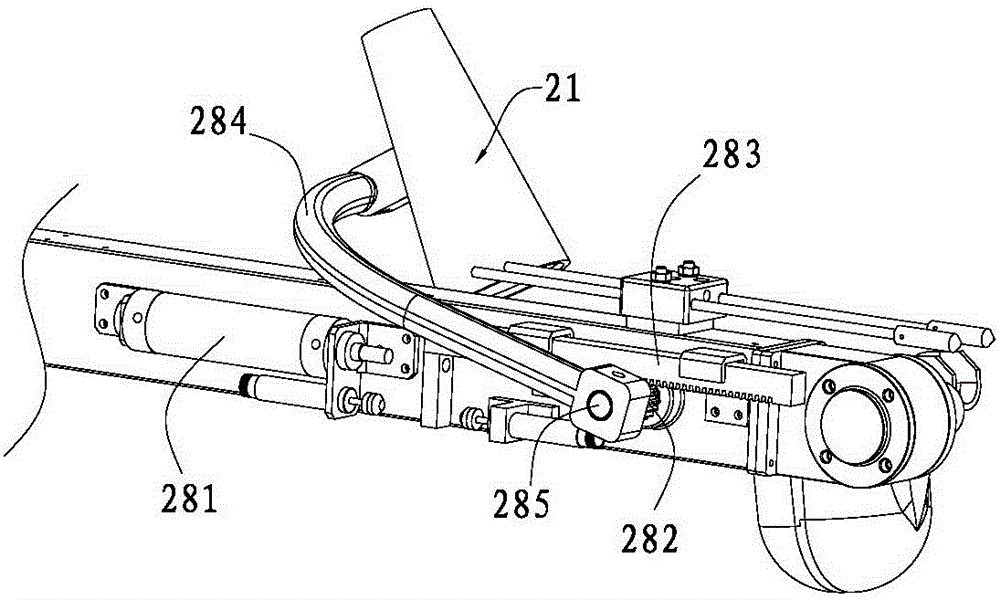

[0018] see figure 2 , the soup dispenser 2 includes a funnel 21, a soup ladle 22, a fixed seat 23, a rotary drive device 24, a rotary seat 25 and a link type manipulator 26, and the fixed seat 23 is fixed on the top of the rotary table 1, so The rotating seat 25 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com