Plate surface grinding equipment

A plate and equipment technology, applied in the field of plate surface grinding equipment, can solve the problems of long processing cycle and delay in production process, and achieve the effect of high film removal efficiency, simple and reasonable structure design, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

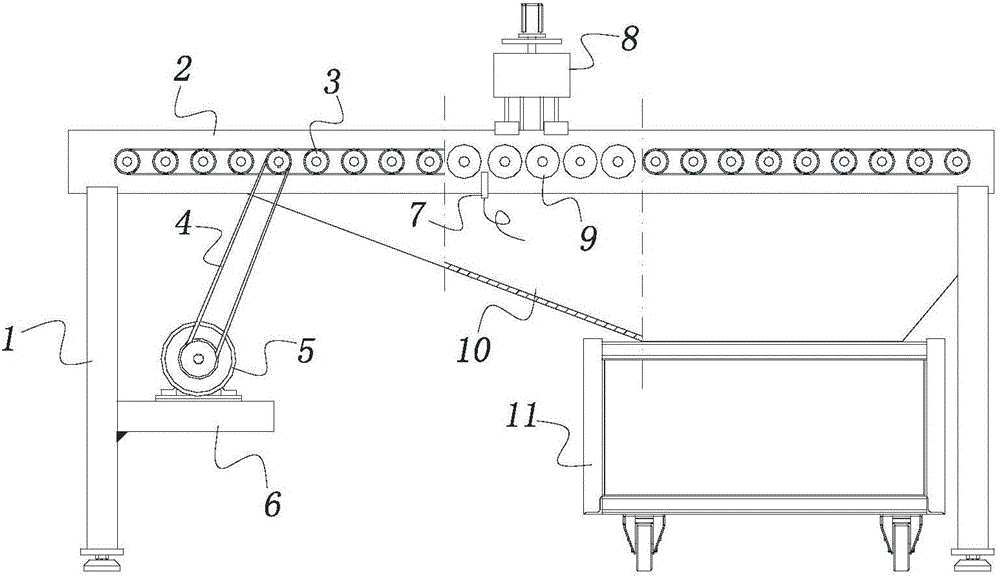

[0013] See figure 1 , the present invention includes two front and rear side plates 2 supported by a plurality of columns 1 and oppositely arranged, between the two side plates 2, a plurality of idler rollers 9 of equal height are erected and installed along the length direction, and each idler roller The end of the same side of the mandrel 9 is provided with a driven sprocket 3, and a chain 4 is sleeved on each driven sprocket 3, and a crossbeam 6 is fixedly connected to the column 1, and a deceleration gear is installed on the crossbeam 6. Machine 5, the driving sprocket on its output shaft adopts chain 4 to connect transmission with wherein a driven sprocket 3. Driven by the reducer 5, each idler roller 9 rotates synchronously and slowly.

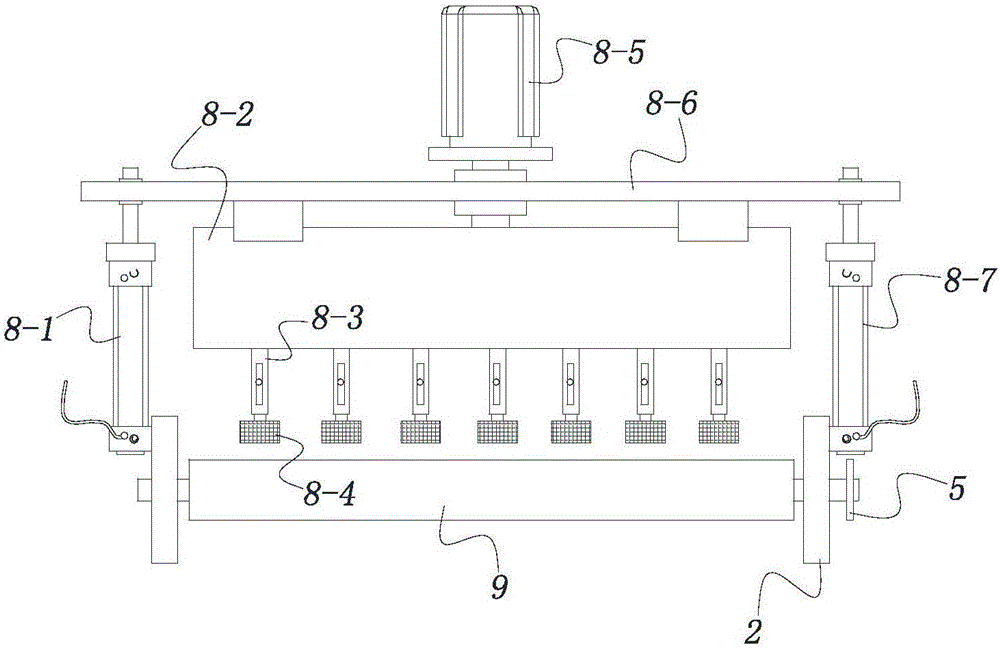

[0014] A grinding mechanism 8 is installed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com