Sectional pressurized organic waste gasifier

An organic waste and gasifier technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low gas quality, incomplete redox reaction, unsatisfactory gasification effect, etc. Secondary pollution, the effect of improving gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

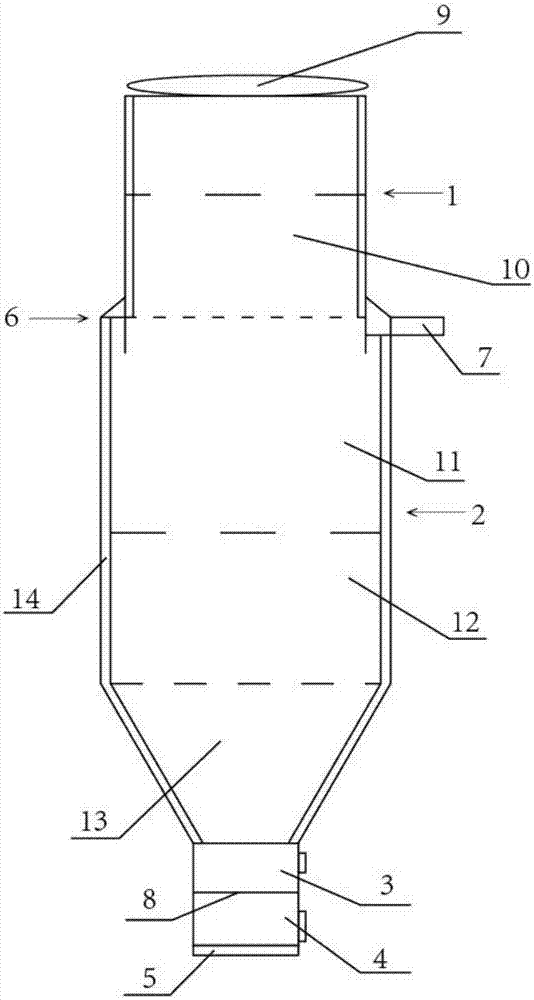

[0017] Embodiment 1 is a preferred embodiment of the present invention, as attached figure 1 Shown: a segmented pressurized organic waste gasification furnace, including an upper furnace body 1, a lower furnace body 1, an ignition area 3, an air supply area 4 and an ash outlet 5 which are sequentially combined and connected, and the upper and lower furnace bodies are two concentric cylinders. The total height of the furnace body is 4000 mm, the height of the lower furnace body 2 is 2000 mm, the diameter is 1500 mm, the height of the upper furnace body 1 is also 2000 mm, and the diameter is reduced to 80% of the diameter of the lower furnace body 2 1 diameter is 1200mm. The bottom of upper furnace body 1 stretches into lower furnace body 2 top slightly, and about 20 centimeters is deep, with the steel plate of same material with furnace body as a whole with certain inclination welding upper and lower two furnace bodies. The difference in diameter between the upper furnace bod...

Embodiment 2

[0024] Embodiment 2 is another preferred embodiment of the present invention. In embodiment 2, the diameter of the lower furnace body 2 is 2000 mm, and the diameter of the upper furnace body 1 is 1500 mm. The bottom end of the upper furnace body 1 slightly extends into the lower furnace body 2 top. , about 10 centimeters deep, it is the same as embodiment 1.

[0025] The working principle of the present invention is: in the gasification process of garbage organic matter, due to the narrowing of the upper furnace body 1, the gas in the furnace moves from bottom to top, the gas density in the upper furnace body 1 increases, and the gas in the upper furnace body 1 rises to After the top, under the greater pressure, the rising gas returns quickly, so the density of the middle pyrolysis zone 11 will increase correspondingly, and the pyrolysis rate will also increase accordingly. The reduction zone 12 and oxidation zone 13 in the lower part The speed is also accelerated accordingly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com