Slagging device of crude benzene regenerator and slagging method

A regenerator and residue technology, applied in organic chemistry, absorption purification/separation, petroleum industry, etc., can solve problems such as blockage of regenerator slag discharge pipeline, economic loss, environmental hazards, etc., to reduce steam consumption and optimize oil washing quality , harm reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

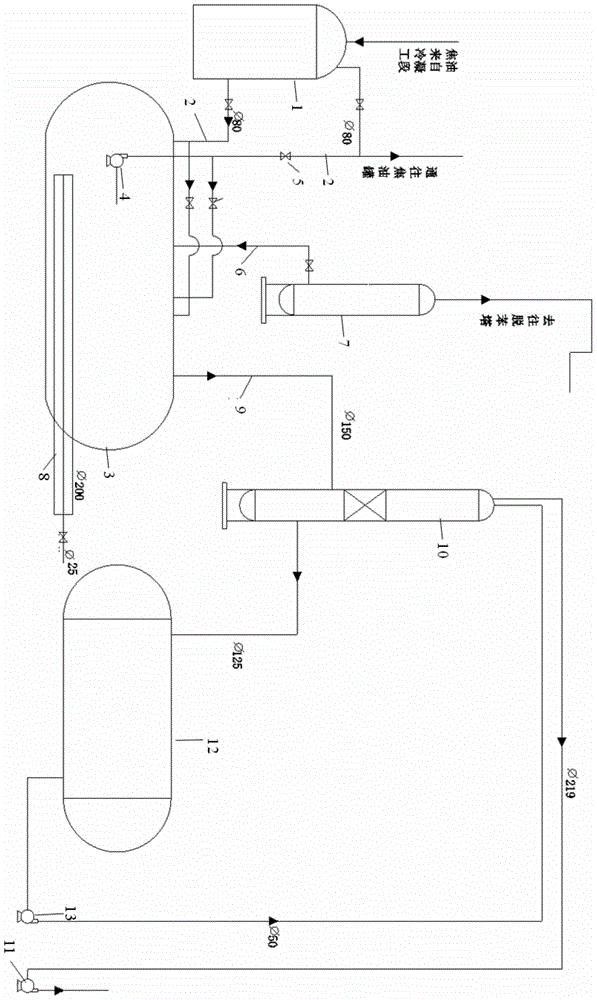

[0017] as attached figure 1 As shown, a crude benzene regenerator slagging device includes a tar tank 1, a tar pipeline 2, a residue tank 3, a residue pump 4, an external delivery valve 5, a slag discharge pipeline 6, a regenerator 7, a heater 8, and a discharge Pipe 9, spray tower 10, induced draft fan 11, circulating water tank 12, spray pump 13, steam purging device;

[0018] The tar tank 1 receives the tar from the condensing section, and the bottom is connected with the residue tank 3 through the tar pipeline 2, the residue tank is provided with a slag discharge tank, and the residue tank is connected to the top of the tar tank through another tar pipeline. A tar pipeline is provided with a residue pump 4 and an outgoing valve 5 to send the residue diluted with tar back to the tar tank 1, and the residue tank is connected to the valve at the bottom of the regenerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com