Method for recovering methanol from tail gas washing water in low-temperature methanol washing technology

A low-temperature methanol washing and tail gas washing technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of washing water corrosion of methanol/water separation towers, etc., and achieve wide industrial application value , the effect of reducing energy consumption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the present invention, preferred embodiments of the present invention are described below in conjunction with specific embodiments, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the scope of protection required by the present invention.

[0024] According to the method for recovering methanol from tail gas washing water in the low-temperature methanol washing process provided by the invention, the following flow process is adopted:

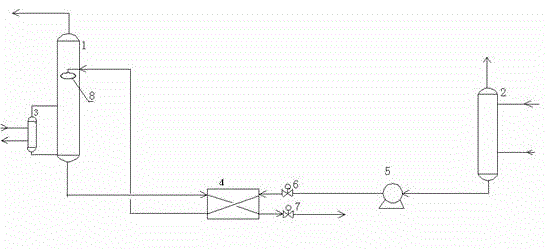

[0025] Such as figure 1 As shown, in the low-temperature methanol washing tail gas scrubbing, the desalted water enters the tail gas scrubber 2 to absorb the methanol and CO in the tail gas 2 and other acid gases, forming a dilute methanol solution, because CO 2 Soluble in it, so the washing water is acidic, with a pH value of about 5.5. After the washing water is pressurized by the pump 5, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com