Biological sludge heating and thermal hydrolysis system and process

A technology of biological sludge and thermal hydrolysis, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment through temperature control, etc., can solve the problem of increasing the amount of sludge treatment and processing energy consumption, heating needs Long time, large steam consumption and other problems, to achieve the effect of improving mixing efficiency and heat transfer efficiency, reducing heating time and steam consumption, and enhancing heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

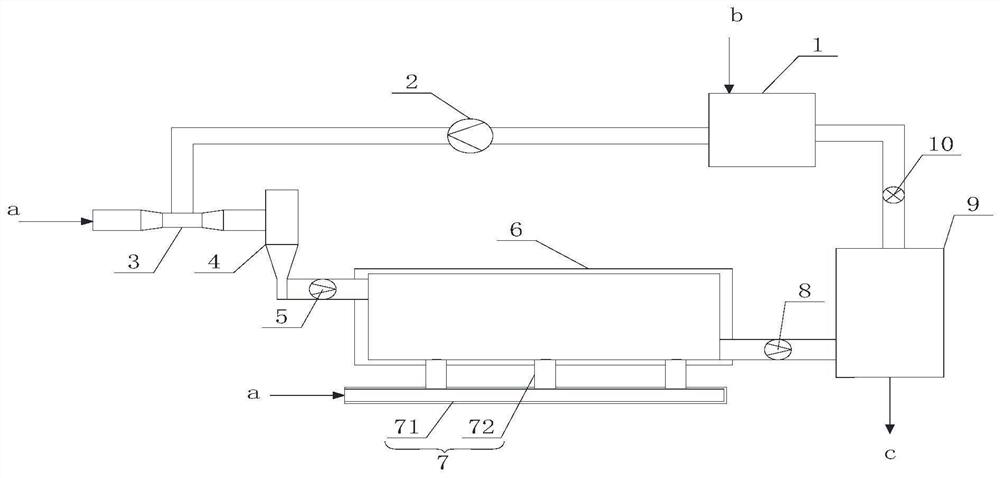

[0044] A biological sludge heating and thermal hydrolysis system, such as figure 1 As shown, it includes material preheater 1, material delivery pump 2, primary steam ejector 3, material storage 4, feed pump 5, thermal hydrolysis reactor 6, discharge pump 8, A steam flasher 9 and a pressure relief valve 10, as well as a secondary steam ejector 7 for heating the biological sludge in the thermal hydrolysis reactor 6.

[0045] In this embodiment, the secondary steam ejector 7 includes an external steam delivery pipe 71 and at least one external steam injection pipe 72. One end of the external steam injection pipe 72 communicates with the external steam delivery pipe 71, and the other end communicates with the external steam delivery pipe 71. The hydrolysis reactor 6 communicates.

[0046] In this embodiment, the thermal hydrolysis reactor 6 is a cylindrical structure arranged horizontally, and the biological sludge enters the thermal hydrolysis reactor 6 from the material inlet ...

Embodiment 2

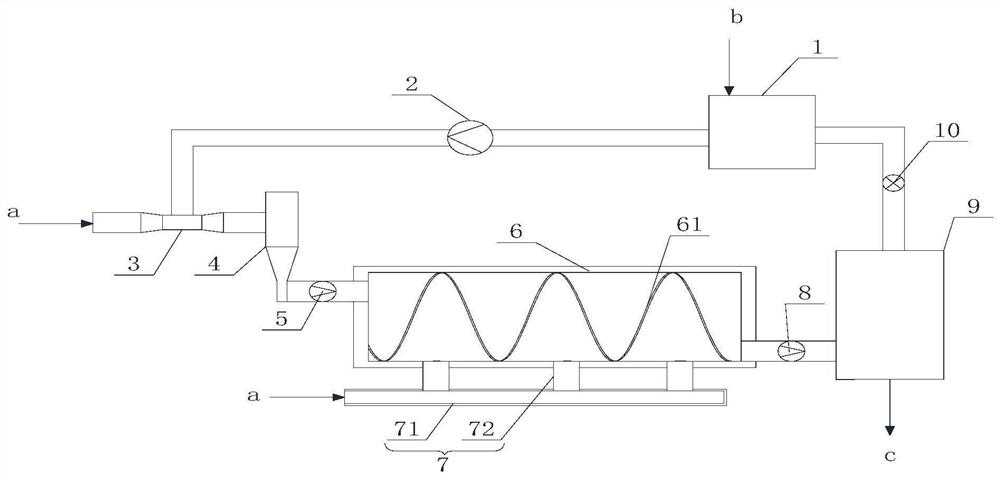

[0052] A biological sludge heating and thermal hydrolysis system, such as figure 2 and 3As shown, it includes material preheater 1, material delivery pump 2, primary steam ejector 3, material storage 4, feed pump 5, thermal hydrolysis reactor 6, discharge pump 8, A steam flasher 9 and a pressure relief valve 10, as well as a secondary steam ejector 7 for heating the biological sludge in the thermal hydrolysis reactor 6.

[0053] In this embodiment, the secondary steam ejector 7 includes an external steam delivery pipe 71 and at least one external steam injection pipe 72. One end of the external steam injection pipe 72 communicates with the external steam delivery pipe 71, and the other end communicates with the external steam delivery pipe 71. The hydrolysis reactor 6 communicates.

[0054] In this embodiment, the thermal hydrolysis reactor 6 is a cylindrical structure arranged horizontally, and a spiral deflector 61 is arranged inside the thermal hydrolysis reactor 6 . In...

Embodiment 3

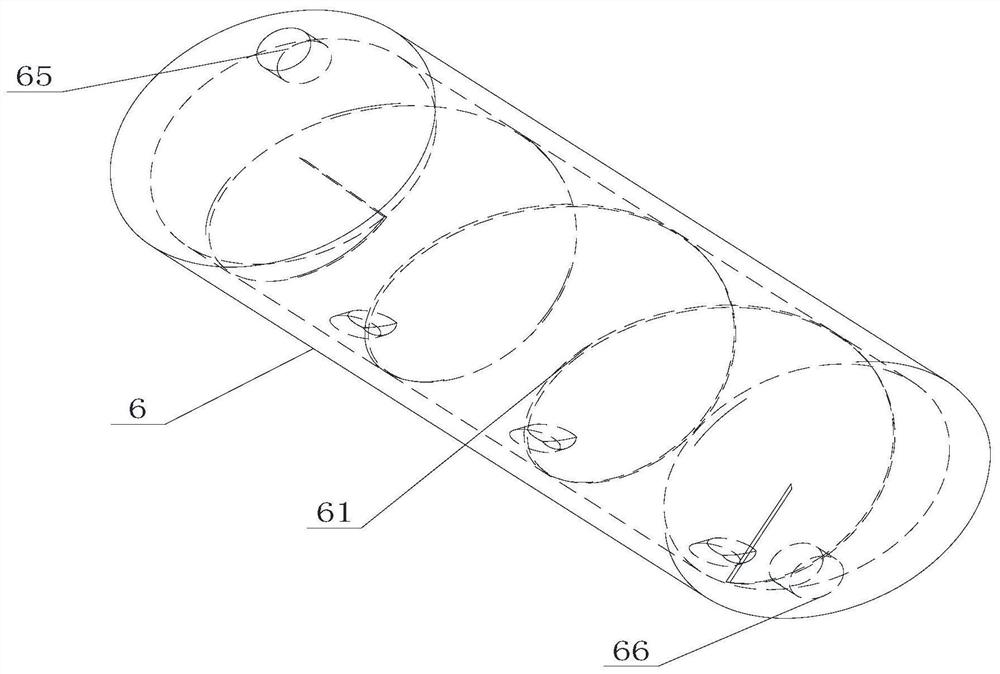

[0059] A biological sludge heating and thermal hydrolysis system, such as Figure 4 and 5 As shown, it includes material preheater 1, material delivery pump 2, primary steam ejector 3, material storage 4, feed pump 5, thermal hydrolysis reactor 6, discharge pump 8, A steam flasher 9 and a pressure relief valve 10, as well as a secondary steam ejector 7 for heating the biological sludge in the thermal hydrolysis reactor 6.

[0060] In this embodiment, the secondary steam ejector 7 includes an external steam delivery pipe 71 and at least one external steam injection pipe 72. One end of the external steam injection pipe 72 communicates with the external steam delivery pipe 71, and the other end communicates with the external steam delivery pipe 71. The hydrolysis reactor 6 communicates.

[0061] In this embodiment, the thermal hydrolysis reactor 6 is a cylindrical structure arranged horizontally, and the thermal hydrolysis reactor 6 is provided with an inclined guide plate 62 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com