Online solutionizing treatment production line for U-shaped heat exchange pipes

A technology of solid solution treatment and heat exchange tubes, which is applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of fragile workpieces, low efficiency, and high labor intensity, so as to improve production efficiency, save production man-hours, and guarantee The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below in conjunction with specific drawings.

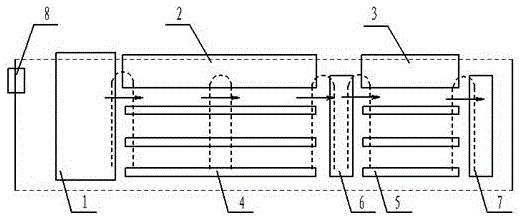

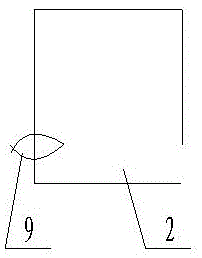

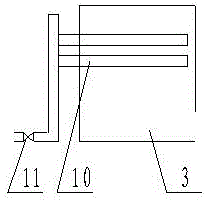

[0024] like figure 1 , figure 2 As shown: the U-shaped heat exchange tube online solution treatment production line, the equipment in order from left to right is the workpiece placement area 1, the heating furnace area 2, and the spray cooling area 3, which are set before the heating furnace area 2 Conveyor belt 4 in the heating furnace area. Set the conveyor belt 5 in the spray cooling area before the spray cooling area 3. The transfer trolley 6 transfers workpieces between the two conveyor belts. There is an infrared detection system on it. The conveyor belt in the spray cooling area A discharge mechanism 7 is arranged on the 5 side; an electric hoist 8 is installed above the conveyor belt 4 / 5.

[0025] Using method of the present invention, its technological process is:

[0026] ① Lift the U-shaped heat exchange tube to be processed to the workpiece plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com