Electroplating method

A technology of electroplating layer and seed layer, applied in the field of electroplating, can solve the problem of easy existence of holes, and achieve the effect of reducing the discontinuity of the electroplating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

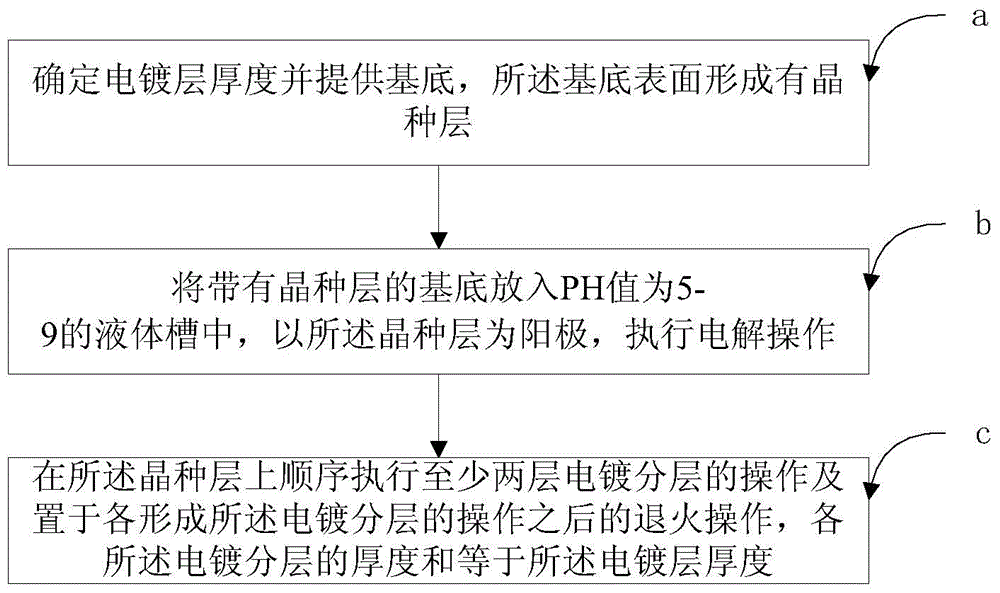

[0016] Combine below figure 1 The technical solutions of the present invention are further described through specific implementation methods.

[0017] figure 1 It is a flow chart of an electroplating method provided by a specific embodiment of the present invention.

[0018] A method of electroplating, comprising:

[0019] Step a, determining the thickness of the electroplating layer and providing a substrate, and a seed layer is formed on the surface of the substrate;

[0020] Step b, putting the substrate with the seed layer into a liquid tank with a pH value of 5-9, using the seed layer as an anode, and performing an electrolysis operation;

[0021] Step c, sequentially performing at least two electroplating layered operations on the seed layer and annealing operations placed after the operations of forming the electroplating layers, the sum of the thicknesses of each of the electroplating layers is equal to the electroplating layer thickness.

[0022] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com