A displacement and unloading structure and construction method of vertical components

A technology of vertical components and construction methods, applied in building construction, building maintenance, construction, etc., can solve the problems of high cost, long construction period, affecting building space, etc., and achieve cost reduction, construction period shortening, and occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

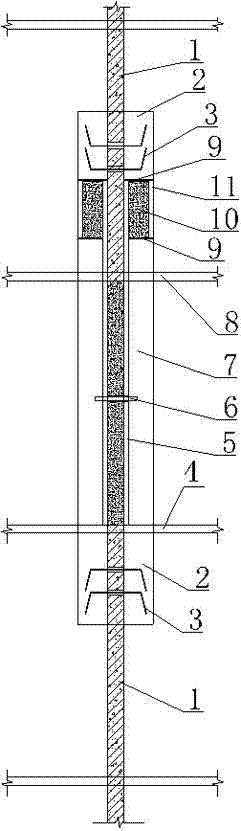

[0032] Such as figure 1 As shown, a replacement and unloading structure and construction method of a vertical member of the present invention, taking a one-story structural column of a certain project as a vertical member for replacement as an example, the construction is carried out according to the following procedures:

[0033] (a) Chisel away the concrete on the floor slab 4 and roof slab 8 of the vertical member 1 that needs to be replaced at the position of the unloading column 7 to ensure that the unloading column 7 is completely separated from the components to be replaced;

[0034] (b) Chisel the surface of the support corbel 2 in contact with the vertical member 1 to increase the reserve of shear resistance, drill holes on the vertical member 1 that needs to be replaced, place the shear reinforcement 3, and the lower support corbel 2 The shear reinforcement 3 is bent downward, and the upper shear reinforcement 3 supporting the corbel 2 is bent upward, which can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com