Formation fluid separation analysis and evaluation method

A formation fluid, separation and analysis technology, applied in earth-moving drilling, wellbore/well components, construction, etc., can solve the problems of less analysis components and unquantified degassing, achieve accurate and timely analysis and interpretation, and improve the interpretation coincidence rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

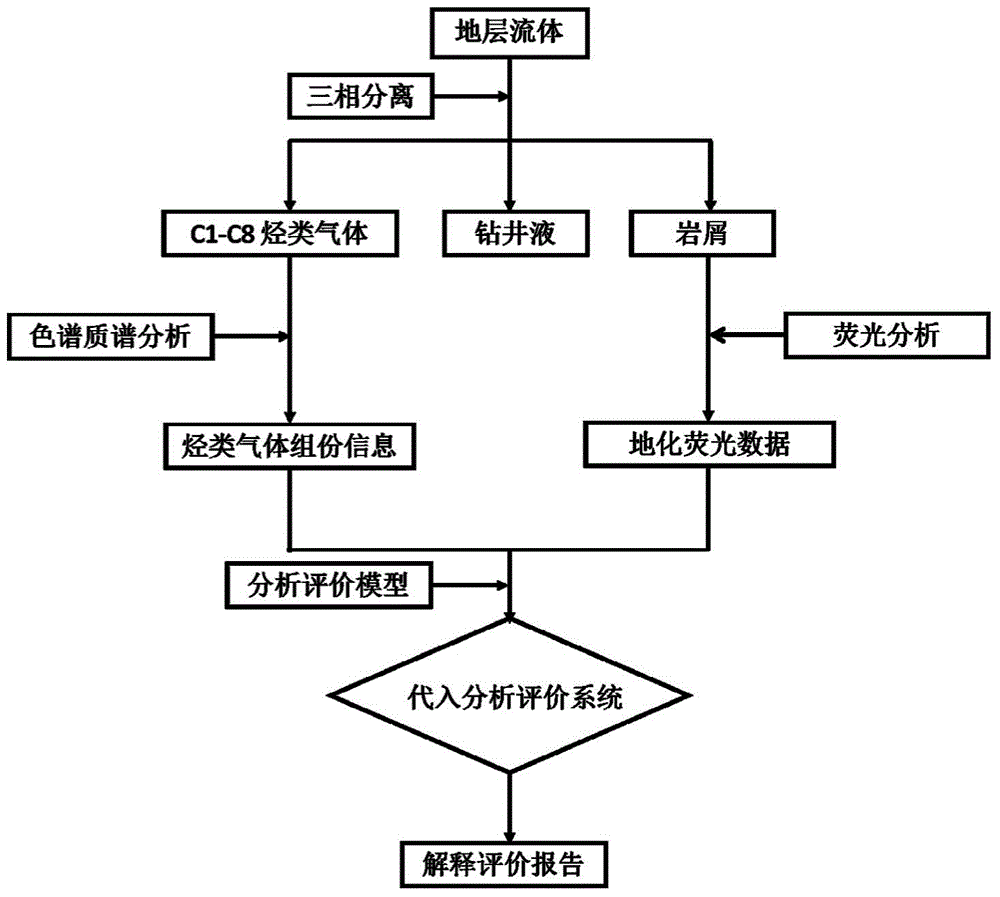

[0024] See figure 1 , The formation fluid separation analysis and evaluation method of the present invention includes the following steps:

[0025] 1) Three-phase separation; first, a high-efficiency and low-resistance multi-tube cyclone separator is used as the pre-separation. After the formation fluid enters the cyclone device from the side in a tangential direction at a certain speed, it rotates according to the shape of the cyclone tube. As the fluid moves to the bottom, the gradually reduced diameter increases the angular velocity and centrifugal force of the fluid. Under the action of the centrifugal force, phase separation occurs. Gas, light particles or liquid gather in the center of the cylinder and move toward the top of the cyclone. It flows out from the top, and the heavy particles and liquid flow out through the bottom of the cone; then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com