Stepping sliding moving support with increased step distance

A sliding frame and sliding technology, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of increased labor intensity, production efficiency, and production efficiency impact, so as to reduce support investment and save The effect of height space and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

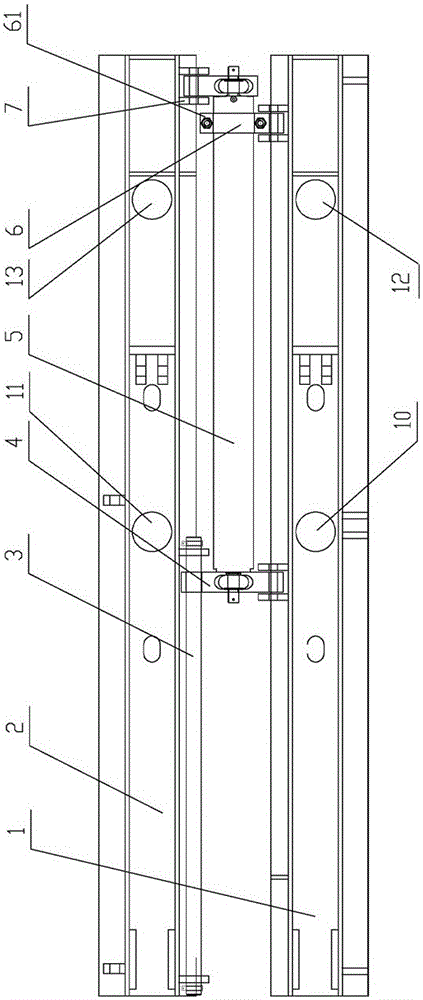

[0012] Such as figure 1 As shown, the present invention includes a main beam 1, an auxiliary beam 2, a guide rod 3, a carriage 4, a stepping jack 5, a carriage holder 7 and the like. Set guide rod 3, carriage fixing seat 7 on subbeam 2, arrange carriage 4, large carriage 6 on main beam 1, the other end of carriage 4 is located on guide rod 3, large carriage 6 includes and The two half-ring guide sleeves 61 that step jack 5 cooperates, and the large slide frame 6 is fixed on the outer circle of step jack 5 by two half-ring guide sleeves 61; The fixed seat 7, the carriage 4 slides on the guide rod 3.

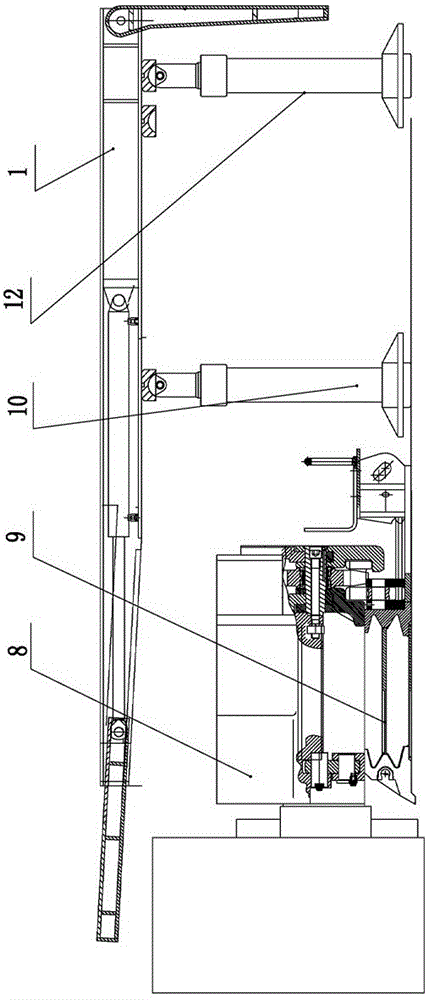

[0013] figure 2 Shown is the supporting schematic diagram of coal shearer 8, scraper machine 9 and the present invention. When the stepping sliding support needs to be moved, the auxiliary beam 2 is in the supporting state (the adjacent frame is also in the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com