Diesel engine automatic preheating device

A technology of preheating device and diesel engine, which is applied in the heat treatment device of fuel, starting of engine, machine/engine, etc., can solve the problems of excessive structural installation size, difficulty in precise control, low preheating power, etc., and achieve ingenious installation position. Reasonable, reduce wear and tear, work smoothly and softly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

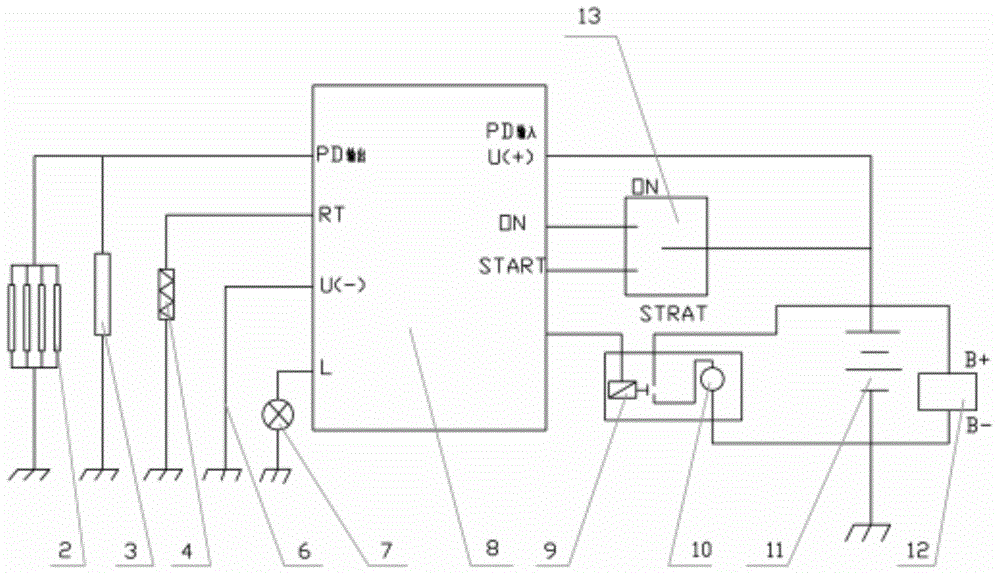

[0011] The structure and principle of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

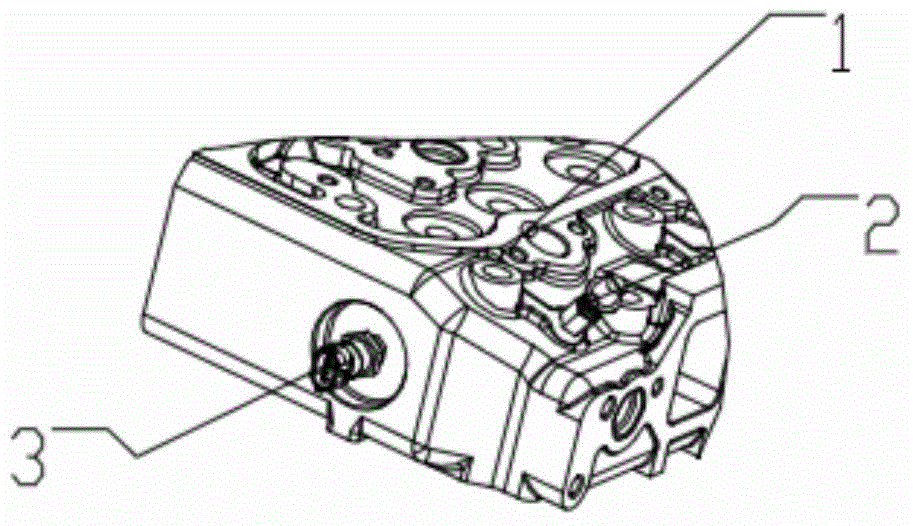

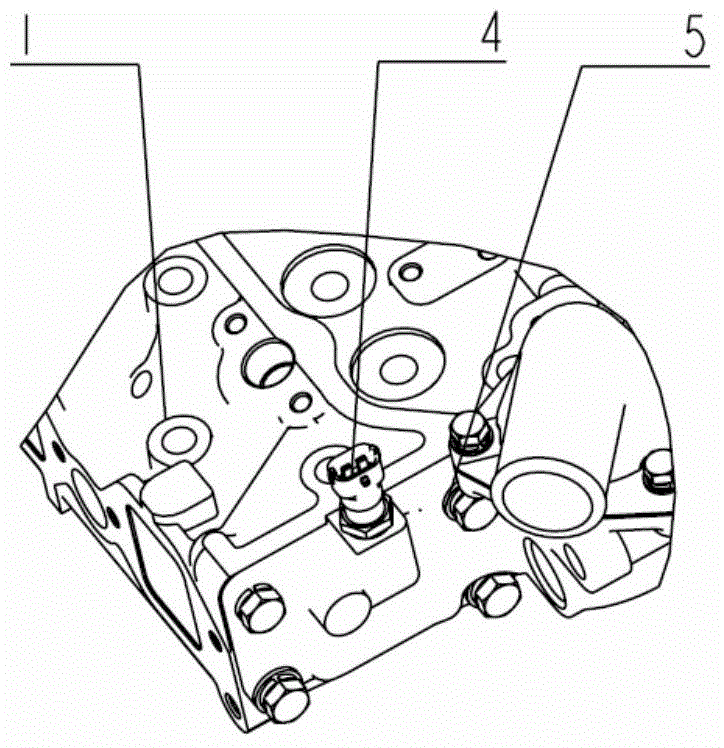

[0012] Diesel engine automatic preheating device, including: cylinder head water jacket, glow plug, water jacket heater, temperature sensor, thermostat body, grounding wire, preheating indicator light, controller, relay, starter, battery, generator and keyed doors etc. Its structural composition is as follows: a preheat plug 2 is installed at the lower left end of the cylinder head water jacket 1, a water jacket heater 3 is installed on the left end side wall of the cylinder head water jacket, and a water temperature sensor 4 is assembled in the small circulation of the thermostat body 5. in the waterway. The controller 8 is respectively connected to the power supply interfaces of the glow plug, the water jacket heater and the temperature sensor through the circuit harness.

[0013] The connection scheme of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com