Silencing device for drainage pipeline of air compressor

A technology for draining pipes and mufflers, which is applied to mechanical equipment, machines/engines, and liquid-variable-capacity machinery, etc., can solve the problems of continuous and sharp noise, influence on-site working environment, and loud noise, and achieve simple structure and improve work efficiency. Environment, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

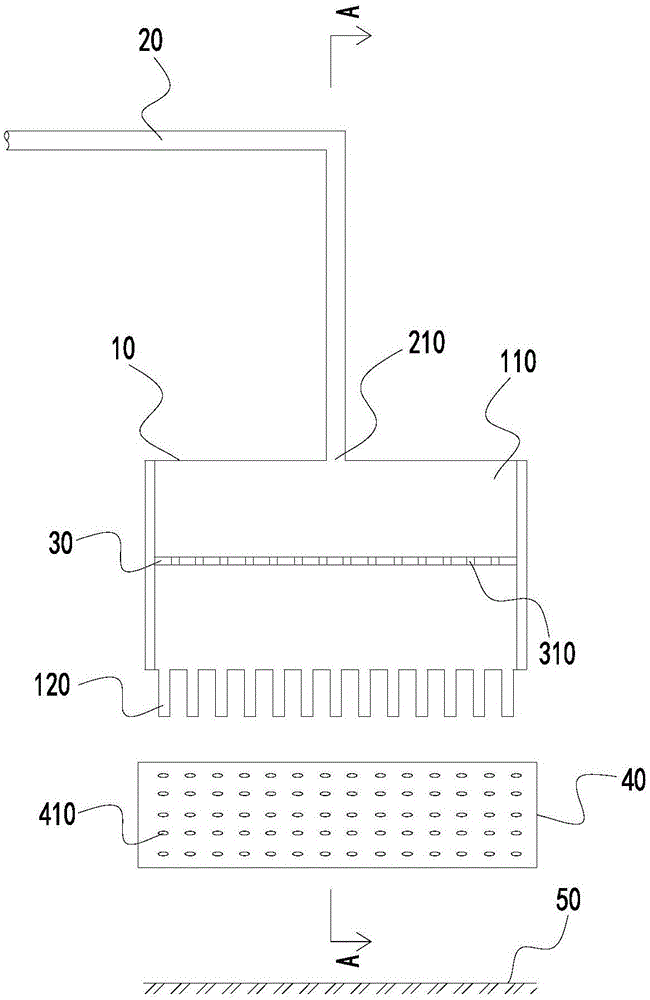

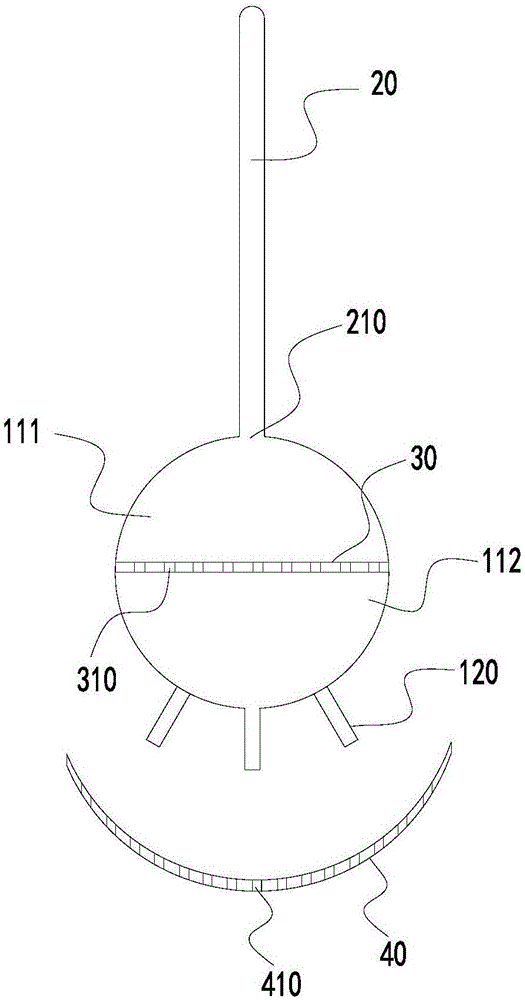

[0019] Such as figure 1 with figure 2 As shown, a kind of silencer device for air compressor drain pipeline includes a muffler 10 provided with a cavity 110, the drain opening 210 of the drain pipeline 20 is communicated with the cavity 110, and the bottom of the muffler 10 is provided with a drain connected to the cavity 110. For the hole 120 , the cross-sectional area of the cavity 110 is larger than the cross-sectional area of the hydrophobic port 210 .

[0020] The condensed water of the air compressor is discharged through the drain pipe 20, and when it flows into the cavity 110 of the muffler 10 from the drain port 210, the condensed water expands in the cavity 110 of the muffler 10 to reduce noise and condense after noise reduction The water is discharged through the drain hole 120 at the bottom of the muffler 10, which meets the requirement that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com