Light source structure of automotive LED headlamp

A technology of LED light source and automobile headlight, which is applied in the direction of light source, headlight, electric light source, etc., can solve the problems of high cost, technical difficulty and high cost, and achieve the effect of low cost and difficult selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

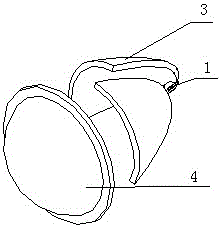

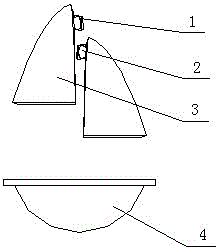

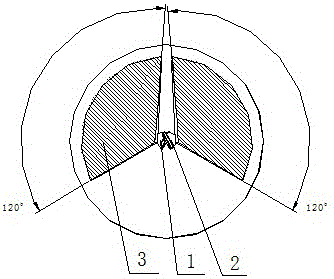

[0030] A light source structure of an LED automobile headlight, such as figure 1 and figure 2 , including LED light source one 1, LED light source two 2, reflective bowl 3, optical lens 4 and light blocking sheet 5, reflective bowl 3 adopts reflective bowl 3 with at least two or more optical centers, LED light source one 1 is arranged on reflective bowl 3 One of the optical centers, the second LED light source 2 is located at the other optical center of the reflective bowl 3, and the first LED light source 1 and the second LED light source 2 are staggered to meet the size of the LED light source. image 3 , the optical lens 4 is located at the light outlet of the reflective bowl 3, the light blocking sheet 5 and the optical lens 4 are distributed along a line with the optical lens 4 as the axis, the optical lens 4 is located at the light outlet of the axis, and the light blocking sheet 5 is located inside the optical lens 4 .

[0031] The first LED light source 1 and the se...

Embodiment 2

[0040] The structure of embodiment two is basically the same as that of embodiment one. The difference between embodiment two and embodiment one is that the reflective bowl 3 of embodiment two adopts an integral reflective bowl 3, LED light source one 1, LED light source two 2 Stagger the setting in the direction perpendicular to the central axis of the optical lens 4, such as Figure 5 .

[0041] In Embodiment 1 and Embodiment 2, the light energy emitted by LED light source one 1 and LED light source two 2 is refracted into a required light pattern through a unified optical lens 4, and the reflective bowl 3 is a reflective surface of light. LED light source one 1, LED The light emitted by the light source 2 is respectively reflected by the reflective bowl 3, and then refracted by the optical lens 4, and the optical lens 4 is located on the outer surface of the light outlet for refraction and appearance effects.

[0042] The LED automobile headlight optical module structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com