Method for baking silkworm cocoons

A baking method and silkworm cocoon technology, which is applied in the field of baking silkworm cocoons, can solve the problems of uneven heating of silkworm cocoons, affecting the baking quality, etc., and achieve the effect of convenient picking and placing, reducing heat energy waste, and convenient picking and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

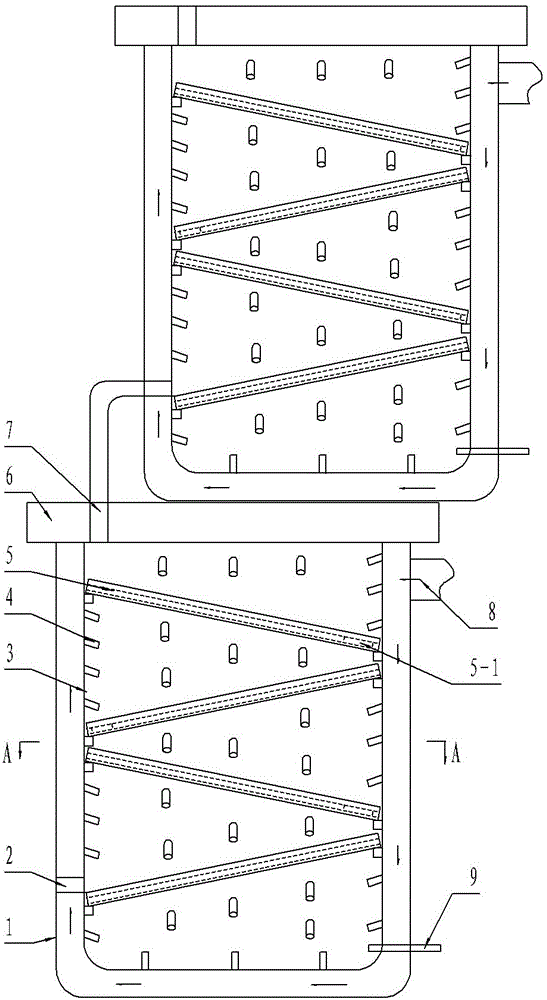

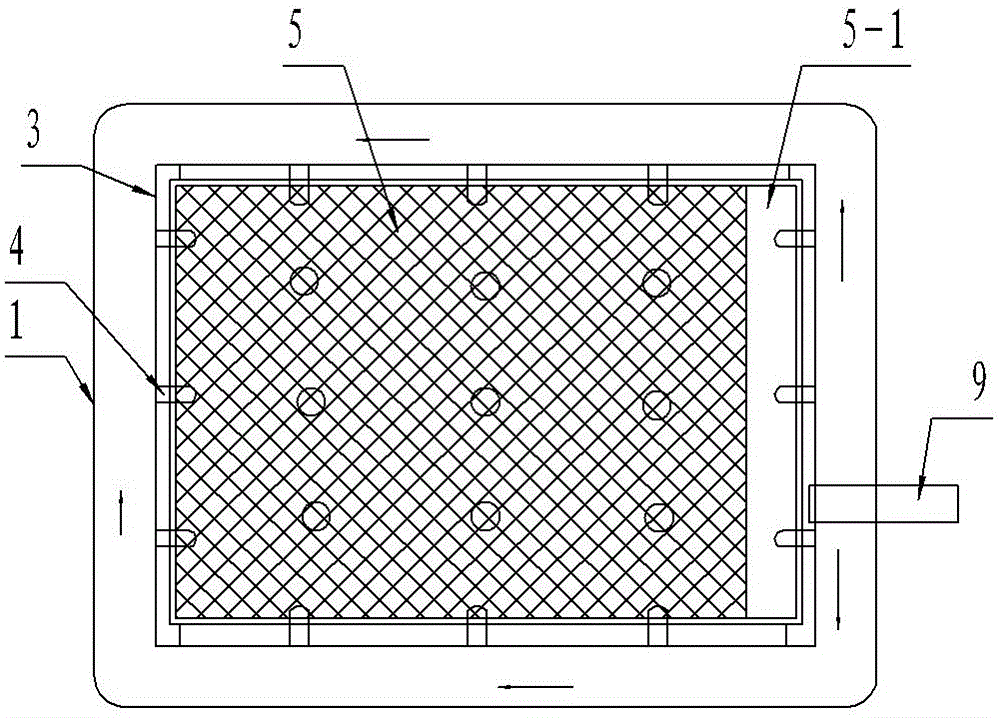

[0013] The cocoon roasting method of the present invention comprises using a cocoon roasting device to roast the cocoons, such a cocoon roasting device as figure 1 , figure 2 Shown, it comprises casing, and each casing is provided with casing cover 6, has the elongated entrance 7 that is used to enter the casing inner wall and is used to enter silkworm cocoon on the casing cover 6. The box wall of the box body has inner wall 3 and outer wall 1 double-layer, and the top of box outer wall 1 is provided with heat conduction opening 8, and heat conduction opening 8 is connected with hot air device, and hot air is input between the box walls of the box body. The inner wall 3 of the box is provided with a plurality of heat pipes 4 inclined downward, and the inner wall 3 of the bottom of the box is provided with heat pipes 4 vertically upward, so that a double-helix hot air flow is generated inside the whole box. The casing is provided with a plurality of screens 5 which are inclin...

Embodiment 2

[0016] The silkworm cocoon drying device has three layers of cabinets stacked, from top to bottom are the upper cabinet, the middle cabinet, and the lower cabinet. The structure of each cabinet is as in Embodiment 1.

[0017] Its baking method comprises the following steps: A, adjust the inclination of the screen in each box, and keep the time for the first row of silkworm cocoons to fall to the box outlet for 60 minutes; Control at 75°C to 78°C, put in silkworm cocoons, row after row of silkworm cocoons are put into the long-shaped inlet of the box; C, 50 minutes after putting the first row of silkworm cocoons into the inlet of the upper box, it is the middle layer The box is fed with hot air, and the temperature is controlled at 70°C to 75°C. At this time, the first row of silkworm cocoons will fall into the first screen of the middle layer box; After 10 minutes, pass hot air into the casing of the lower floor, and the temperature is controlled at 65°C to 70°C. At this momen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com