Great-capacitance capacitive liquid level sensor suitable for dynamic environment

A liquid level sensor and dynamic environment technology, which is applied in the field of liquid level sensors, can solve problems such as inability to adapt to the dynamic environment, and achieve the effect of ensuring test life and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

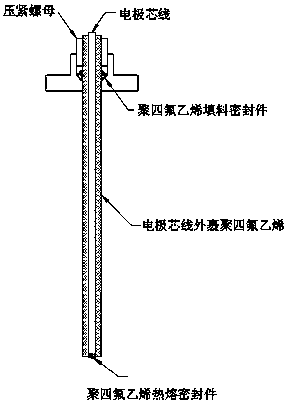

Image

Examples

Embodiment Construction

[0017] Such as image 3 The schematic diagram of liquid level measurement by capacitance method is shown in the figure, and the detection electrode with insulating sleeve and its equivalent circuit diagram are pointed out in the figure. image 3 It can be seen that the top of the liquid surface is C 1 and C 2 Capacitors in series, while the lower part of the liquid is C 3 and C 4 series connection of capacitors, C 总 The output capacitance of the liquid is the parallel connection value of the two series capacitors on the liquid surface and below.

[0018] The following calculates the size of each capacitance value separately:

[0019]

[0020] When measuring conductive dielectric liquids, ε 1 ε 2 ;ε 1 ε 3 Capacitance C 4 In a short circuit state, the capacitance of the lower part of the liquid surface is only determined by the capacitance value of C3.

[0021]

[0022] Assuming that the metal liquid storage tank is cylindrical with a diameter of D, the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com