Marking method for TEM chip sample

A marking method and sample technology, applied in the preparation of test samples, etc., can solve the problems of not remembering the relative position of the target unit, unable to confirm the position of the target unit, unable to operate, etc., so as to reduce wasted time, reduce accidental injury rate, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] In order to achieve the above object, the present invention provides a kind of labeling method of TEM chip sample, mainly comprises the following steps:

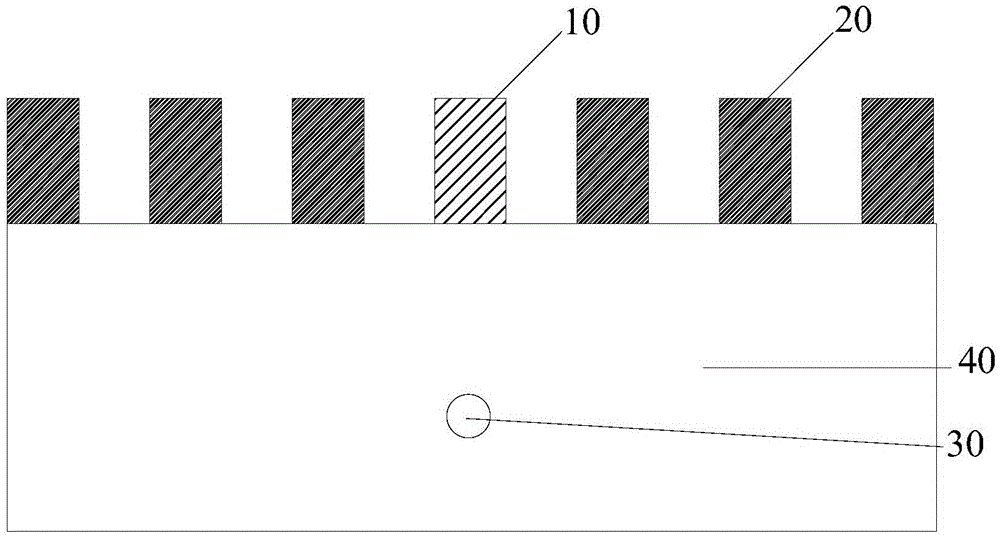

[0023] Step 1: Find the target area that needs to be observed and analyzed in the TEM chip sample. Please refer to image 3 , the target area to be observed and analyzed in the TEM chip sample is a tiny repeating unit area such as a polysilicon gate or a metal lead. direction, several unit structures identical to each tiny repeating unit are arranged side by side, that is, repeating unit structures 20 . Generally, the target areas 10 that need to be observed and analyzed are all failure areas, but even under a transmission electron microscope, these areas are generally simil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com