Graphene coated tilted fiber grating-based liquid refractive index sensor

A technology of tilted fiber grating and liquid refractive index, which is applied in the measurement of phase influence characteristics, etc., can solve the problems of low sensitivity, reduce tilted fiber grating, difficulty in achieving sensitivity, etc., and achieve the effect of high sensitivity and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

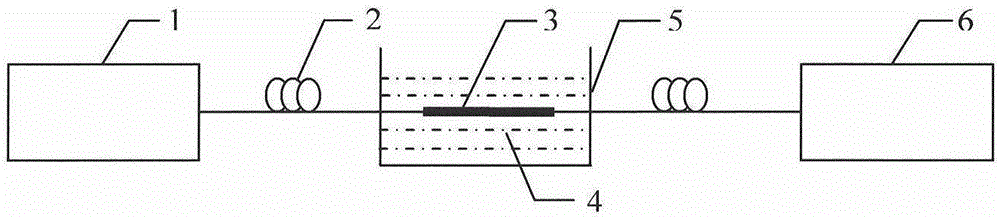

[0022] See attached figure 1 , a liquid refractive index sensor based on a graphene-coated tilted fiber grating includes a broadband light source 1 , a single-mode fiber 2 , a tilted fiber grating 3 , a sample cell 5 and a spectrum analyzer 6 . Among them, the broadband light source 1 is connected to one end of the graphene-coated tilted fiber grating 3 through the single-mode fiber 2, and the other end of the tilted fiber Bragg grating 3 is connected to the spectrum analyzer 6 through the single-mode fiber 2 to monitor and record the transmission spectrum. By sequentially injecting solutions with different refractive indices (such as mixed solutions of water and glycerin with different concentrations) in the sample cell 5 (the small holes on both sides are sealed with UV-curable glue). The sample cell can be removed in the liquid in-situ measurement, directly I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com