Multifunctional gas high-pressure in situ Raman test cell and application thereof

An in-situ Raman and test cell technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of no discovery, few types of in-situ monitoring accessories for Raman spectroscopy, etc., to achieve good performance and expand research fields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

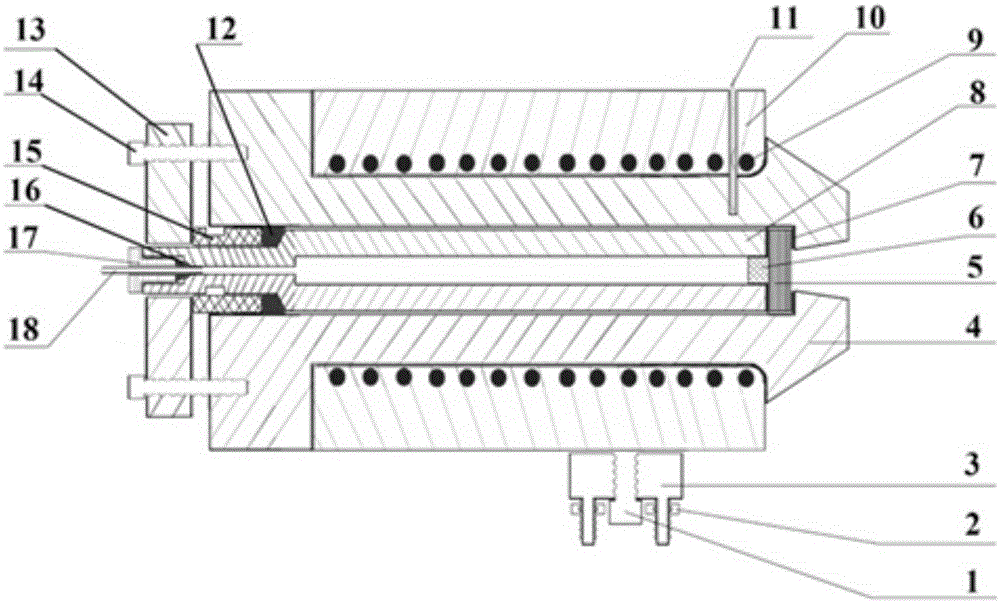

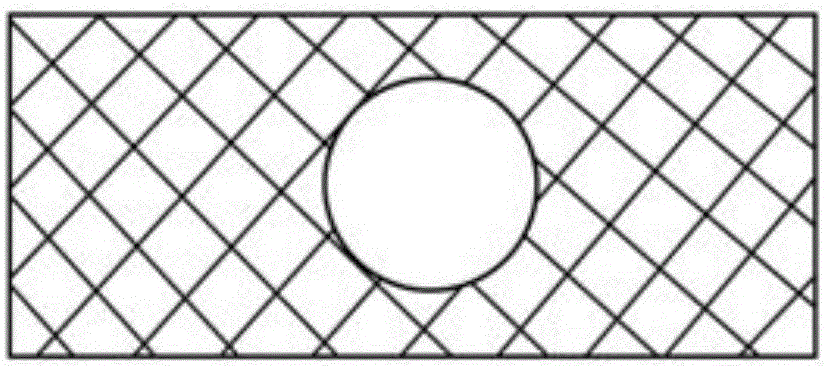

[0053] A multifunctional gas high-pressure in-situ Raman test cell, comprising an outer high-pressure cylinder 4, an inner high-pressure cylinder 8 is arranged in the outer high-pressure cylinder 4, and a window plate 5 is arranged at the front end of the inner high-pressure cylinder 8; The end of the inner high-pressure cylinder 8 is extended to the outside of the outer high-pressure cylinder 4, and is fixedly connected with the end of the outer high-pressure cylinder 4 through fasteners 14; the high-pressure gas source passes through the inner high-pressure cylinder 8 to the The front end of the inner high-pressure cylinder 8 presses the sample 6 to the window 5 .

Embodiment 2

[0055] A multifunctional gas high-pressure in-situ Raman test cell as described in Example 1, the difference is that a thermocouple hole 11 is provided in the outer high-pressure cylinder 4 for inserting a thermocouple.

[0056] A heating part is provided outside the outer high-pressure cylinder 4 . The heating part is a heating pipe 9 .

[0057] An insulation layer 10 is also provided on the outer side of the outer high-pressure cylinder 4 .

Embodiment 3

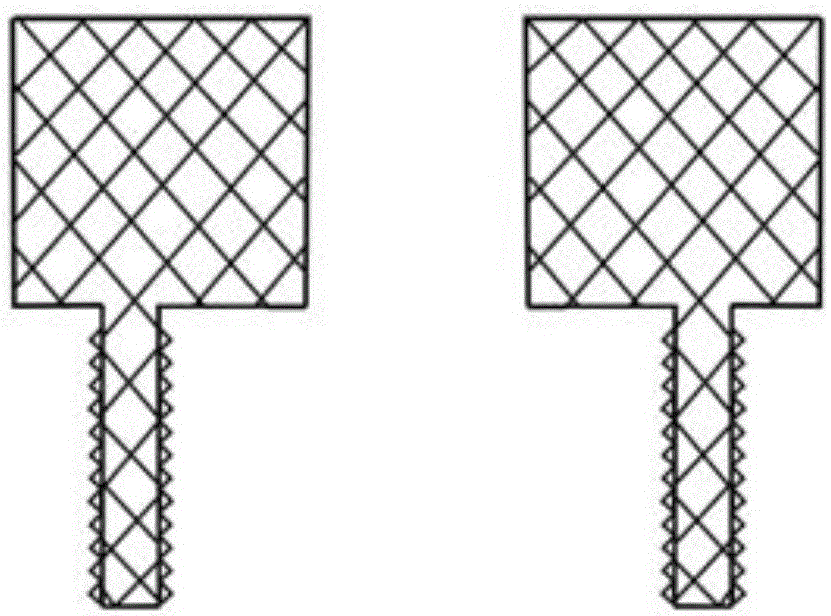

[0059] A multifunctional gas high-pressure in-situ Raman test cell as described in Example 1, the difference is that a height-adjustable base is provided at the bottom of the outer high-pressure cylinder 4 . The height-adjustable base is made of insulating material.

[0060] The height-adjustable base includes a base 3 , connecting screws 1 and fine-tuning nuts 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com