Fuse monitoring bracket for external protection of high-voltage capacitor and on-line monitoring method

A technology for high-voltage capacitors and external protection, which is applied in the field of monitoring brackets and online monitoring of fuses for external protection of high-voltage capacitors. It can solve the problems of no automatic monitoring means for fuses, and achieve convenient and fast monitoring and viewing, appropriate communication distance, and anti-interference strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

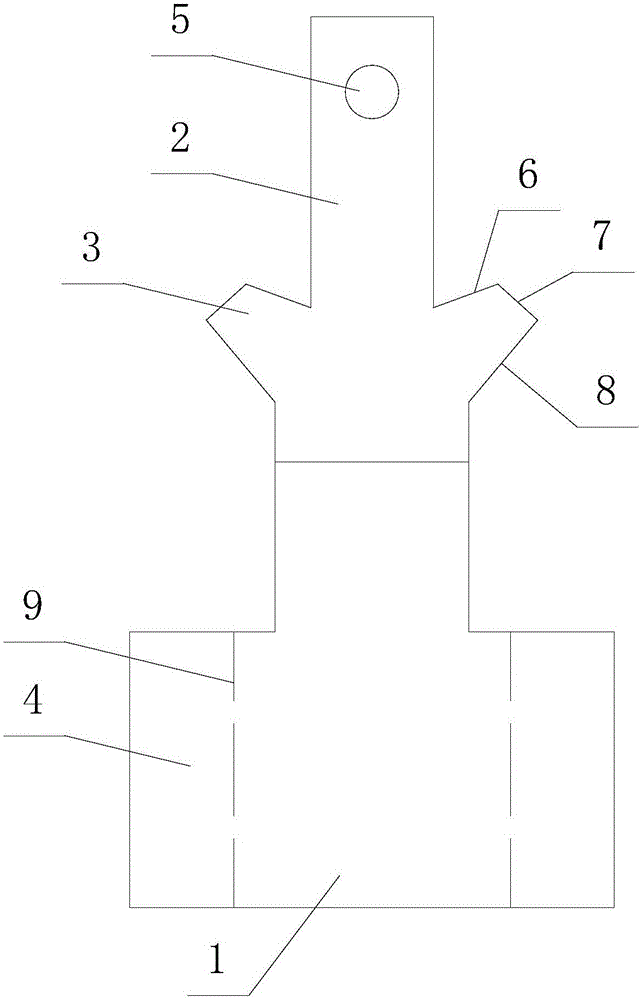

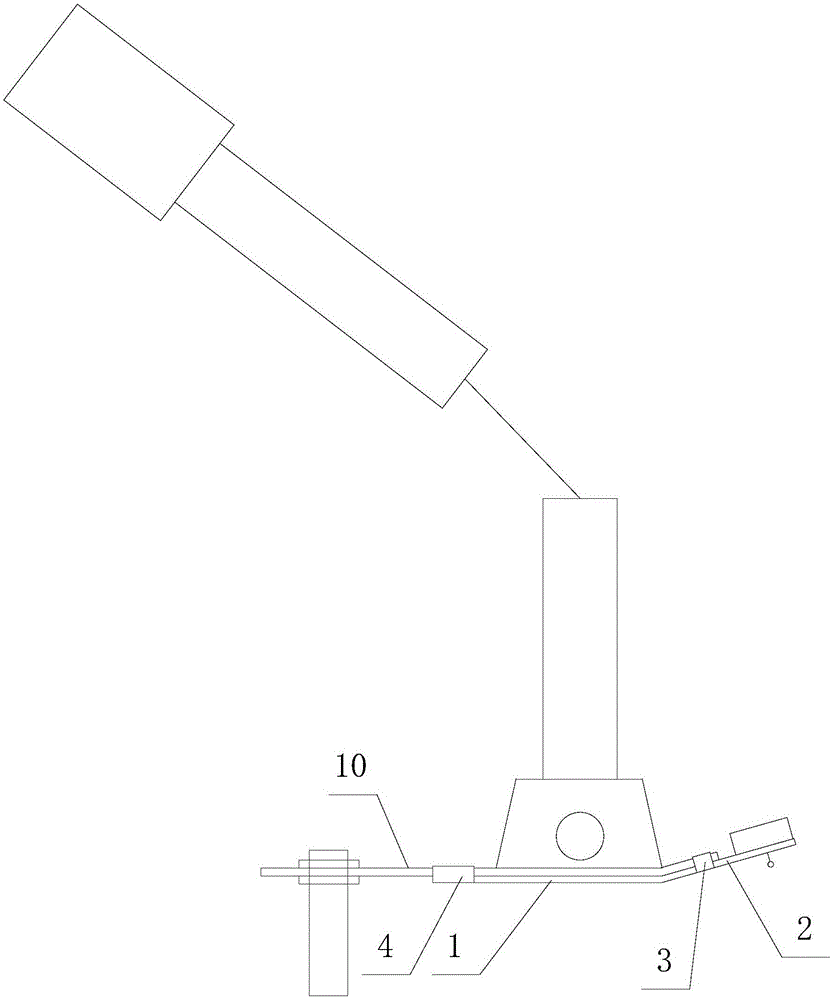

[0030] refer to figure 1 , a fuse monitoring bracket for external protection of high-voltage capacitors, including a fixed plate 1, a mounting plate 2, an upper clamping fastener 3 and a lower clamping fastener 4, the angle between the fixed plate 1 and the mounting plate 2 is an obtuse angle, and the installation A sensor installation hole 5 is opened on the plate 2 , an upper clasping fastener 3 is provided on the lower part of the mounting plate 2 , and a lower clasping fastener 4 is provided on the lower part of the fixed plate 1 .

[0031] The upper clasping fastener 3 is a pair of upper flaps, an upper flap is respectively connected to the left and right side walls of the mounting plate 2, and the upper flap is integrated with the mounting plate 2. The upper flap is quadrilateral, and the upper flap Including the upper side 6, the outer side 7, the lower side 8 and the inner side connected end to end in sequence, the inner side is connected to the mounting plate 2, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com