Parallel robot motion control method with fast response and robust performance

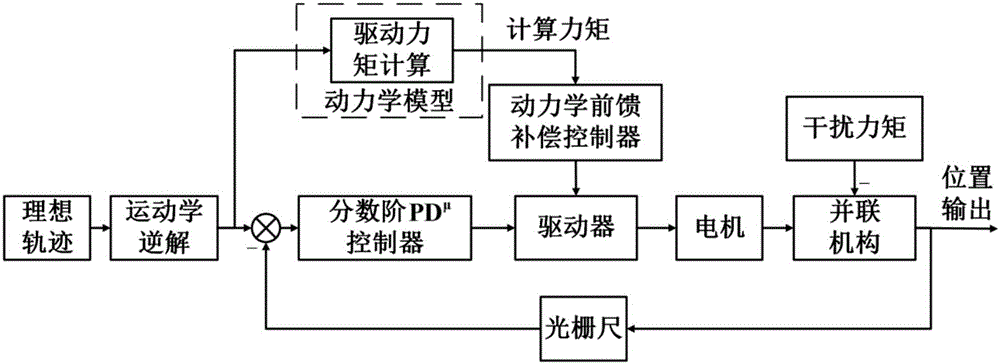

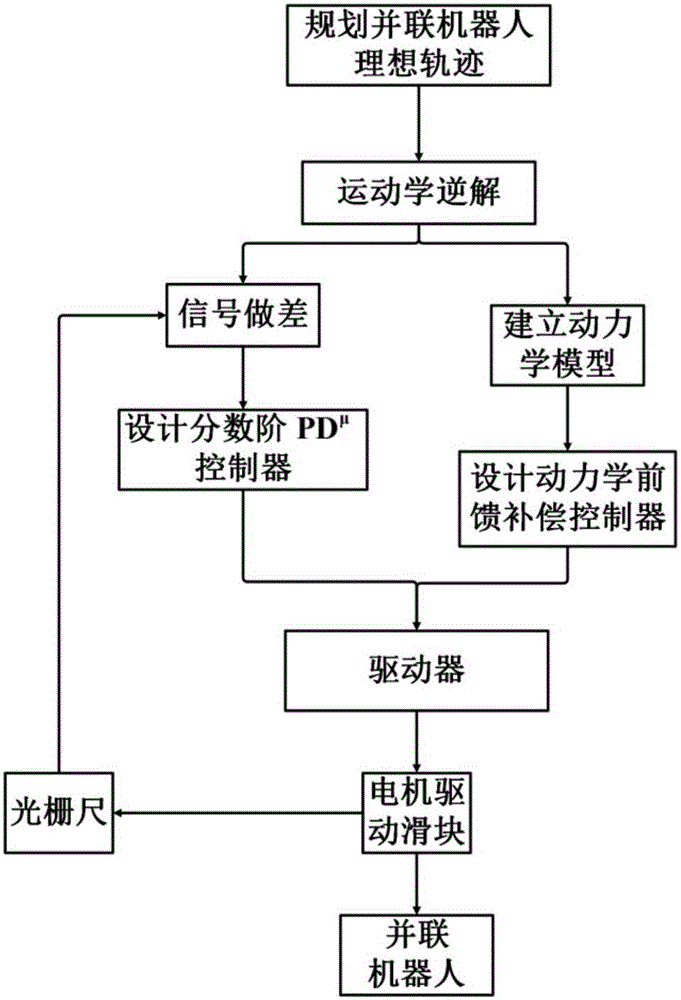

A technology for robot motion and rapid response, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of poor robust performance, insufficient response performance, and low motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

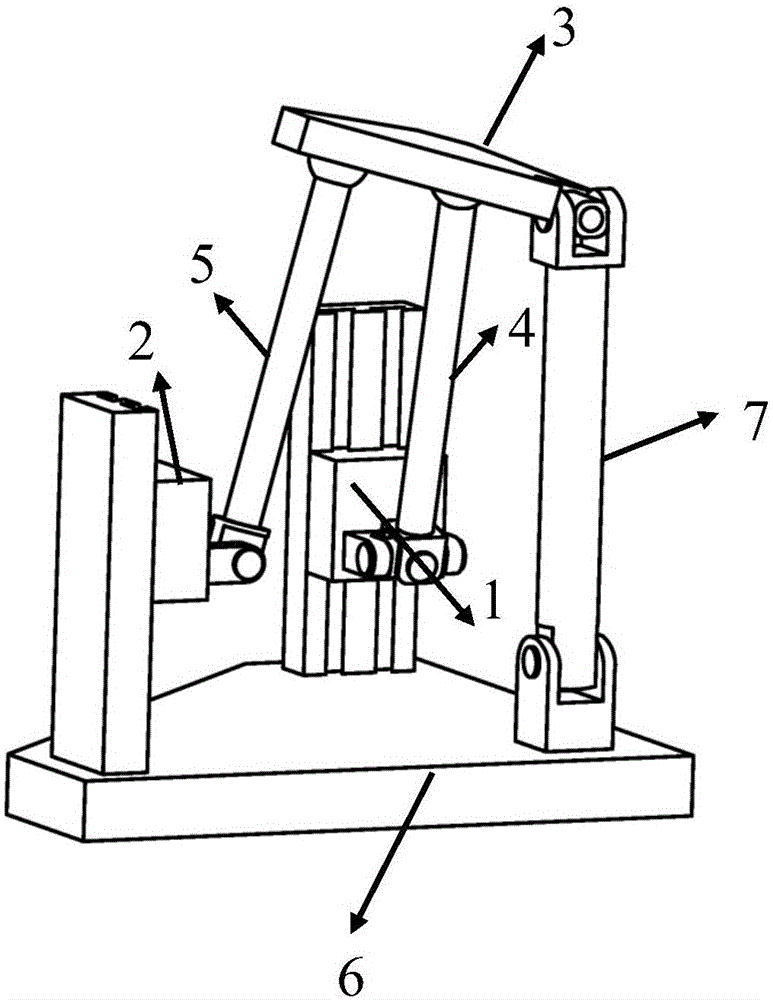

[0083] The proposed motion control method of a parallel robot with fast response and robust performance is applied to a parallel robot with two degrees of freedom in space. The parallel robot is as follows: figure 1 As shown, the robot drives the movement of the terminal movable platform 3 through the movement of the first slider 1 and the second slider 2, the first slider 1 and the second slider 2 are driven by corresponding motors, and the movable platform 3 and the first slider The blocks 1 are connected through the first rod 4, the moving platform 3 and the second slider 2 are connected through the second rod 5, and the moving platform 3 and the static platform 6 are also connected through the third rod 7. The implementation steps of the control method of this embodiment are as follows: 1), the ideal displacement solution of each drive shaft:

[0084] The working space of the parallel robot controlled by this embodiment is α∈(-45° 45 °), β∈(-45°45°), where α, β are tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com