Aluminum-copper explosion cladding CPU cooling fin device

A heat sink, copper-aluminum technology, applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of high cost and low bonding strength of copper-aluminum composite heat sinks, and achieve the goal of not being easy to delaminate and crack, High composite strength and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

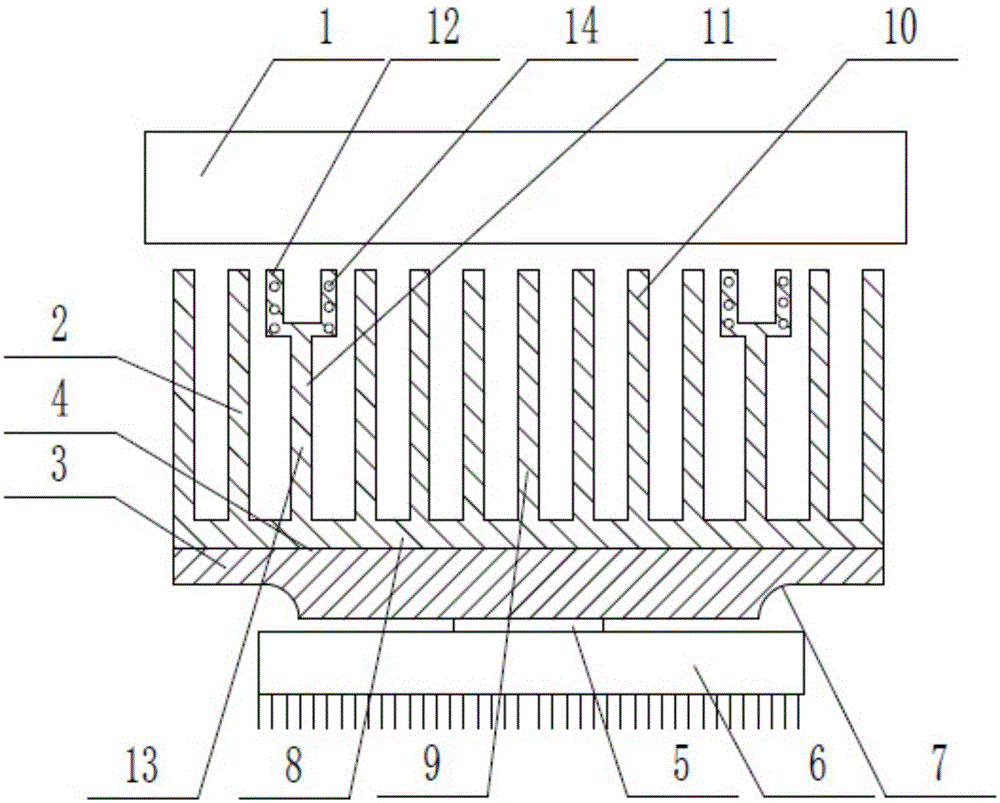

[0020] This embodiment includes a fan 1, heat dissipation fins 2, heat dissipation copper plate 3, explosive composite layer 4, heat conduction silica gel 5, CPU6, the heat dissipation copper plate 3 is arranged directly above the CPU6, and the thickness of the heat dissipation copper plate 3 is 8-10mm. Both sides of the lower end of the heat dissipation copper plate 3 are provided with arc-shaped slots 7, between the heat dissipation copper plate 3 and the CPU 6 are filled with heat-conducting silica gel 5, and directly above the heat dissipation copper plate 3 are provided with heat dissipation fins 2, and the heat dissipation fins 2 include heat dissipation fin seats 8, heat dissipation The fins 9 and the heat dissipation fins 9 are uniformly and vertically arranged on the heat dissipation fin base 8, the heat dissipation fin base 8 is an aluminum plate, and the thickness of the heat dissipation fin base 8 is 3-5 mm. The heat dissipation fins 9 include straight fins 10 and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com